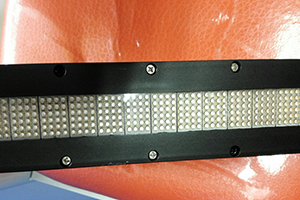

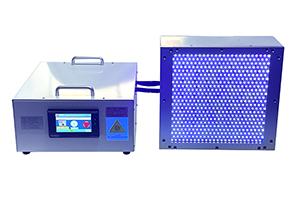

Main Types of Mainly Products : UV 310nm, UV 365nm, UV 375nm, UV 385nm, UV 395nm, UV 405nm, UV 415nm, UV 420nm, Deep UV LED 265nm or 275nm UV LED Packing Size : 335, 4040, 4545, 5050, 6363, 6868, 7070, etc. Business Brand : Japan NICHIA (NCSU033B 、NCSU276A、NCSU033C、NVSU233A、NVSU233A-D1、NVSU233B、NC4U133A、NC4U133B, and maximum power - 365nm NVSU...

continue reading

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español Nederlands

Nederlands العربية

العربية български

български svenska

svenska

+8618924372460

+8618924372460 live:1651063690jennifer

live:1651063690jennifer uvcure@uvspacelight.com

uvcure@uvspacelight.com 0086-18924372460

0086-18924372460