2023-10-24 16:48:50

Before the wafer is thinned, a sticky film is attached to the front of the wafer. The role of the film is to secure the chip on the front of the wafer, which is easy for the grinding machine to grind on the back of the wafer. Generally, the thickness of the silicon wafer before grinding is about 700 μm, and after grinding, the thickness of the wafer becomes 200 μm, or even 120 μm. The wafer thinning process will be based on customer requirements and the application environment of the chip. Before slicing, the back of the wafer will be glued to a film, the role of the film is to stick the chip to the film, which can keep the grain in the cutting process integrity, reduce the collapse generated during the cutting process, and ensure that the grain will not be displaced and dropped during the normal transfer process.

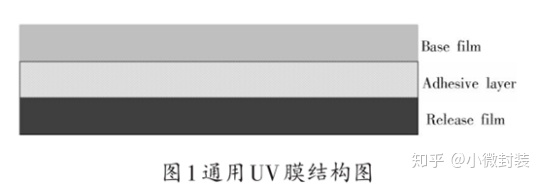

As mentioned above, the chip thinning and cutting process uses a film that is used to fix the wafer chip. In the actual production process, this film generally uses UV tape or blue film. UV tape and blue film play a very important role in the process of chip thinning and cutting, but there are obvious differences in their characteristics.

Whether it is back mask, scribing or thinning, our wafer laminator / wafer mounter can be applied.