High power uv led curing adhesive UV LED spot curing system for mobile phone camera.

model no. :

DSX-UVP60Brand:

DSXUVport of dispatch :

HongKongPayment :

T/T 100% before shipmentoriginal region :

CHINALead Time :

7daysUV LED spot curing DESCRIPTION

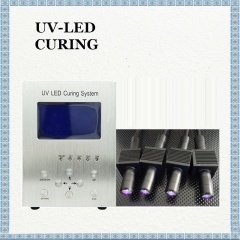

Because of it looks like a very small circle based on the spot area it sents out,we call these machines are UV LED spot curing equipments.According to the different cooling methods of the irradiation heads, we designed the irradiation heads into two ways:nature-cooling and air-cooling.The nature cooling irradiation head is easy to assemble fixed rod,it looks like a pen.And the air cooling irradiation head we use a small radiator fan in it. Threre is a cube in the head part. Two kinds of irradiation heads have become the industry standard at present.

UV LED spot curing equipments'Controller

|

Model |

DSX-UVP60 |

|

Size (mm) |

120*190*220mm |

|

Color |

silver or black |

|

Channel (Heads) |

8 |

|

Consumption |

<60W |

|

Net Weight |

3.050 kg |

|

Step irradiation |

Max 16 steps, eg: light on 5s, light off 2s, light on 3s… |

|

RS232 Interface |

Available |

|

Cooling type |

Fan cooling |

|

Power supply |

100-240V AC 50 Hz, Input Power DC 12 V 5A |

|

Tolerance |

10-150Hz acceleration 50m/s2, half amplitude 0.35mm, X/Y/Z 8 mins. 10 times |

|

Resistance |

150m/s*s 6 directions (up/down, right/left, front/back), each 3 times |

|

Operation |

interface button, foot pedal, RS232 port |

|

Accessory |

user manual, key, power supply cable |

|

Material |

Aluminum |

|

Power setting |

0-100% |

|

Time recording |

max. 999.9s |

Irradiation heads

AIR COOLING

NATRUE COOLING

Feathure & Advantage

*High irradiation intensity up to 8800mw/c㎡

*365nm,385nm,395nm,405nm availabe

*multiple control modes: button, foot pedal, auto

*Environmental friendly, No mercury, No Ozone

*Long working lifespan and low attenuation

*No warm-up time

*Low temperature

*UV output range: 0-100%

Applications

*UV glue, UV adhensive, UV gel curing

*Electronice components fixation curing

*Hard disc, micro-generator, earphone curing

*Watch precision components manufacturing

*DVD/CD light head curing

*Optical lends curing

*LCD sealing curing

*Medical equipment curing

Standard Package

*controller: 1

*led lamps: 1-4

*lens: 1-4

*power adaptor: 1

Caution

1. Package and Transport

When transporting equipment, use random packing materials. Any damage caused by improper packing equipment is not not under warranty.

2. Daily Use and Maintain

LED irradiation head is needed be cleaned regularly. Please use soft buckskin, lens paper and alcohol to clean, ensuring the irradiation intensity and good heat dissipation.

Cleaning the controller regularly. Please wipe with a little alcohol with a cleaning tool. In order to protect the surface of facility, don’t use the volatile liquid or having ammonium hydroxide ingredient to clean (diluent or benzene, etc.).

Attention:

Please do no unauthorized remove the controller and UV LED irradiation head, leading the product to work abnormally.

UV LED Adhesive Curing Machine UV LED Curing Light

UV LED Adhesive Curing Machine UV LED Curing Light

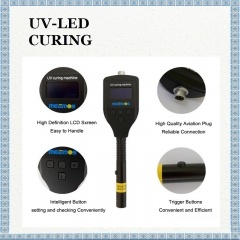

Hand-Held Point Light UV Curing Machine, the first of the world, likes a pen, solidified UV glue, with a USB interface.

Curing UV Glue UV LED Spot Curing System

Curing UV Glue UV LED Spot Curing System

The effect of press polish, UV Glue UV LED Spot Curing System, is better than mercury lamp. Simple operation and high efficiency.

Portable UV Curing System UV Curing Pen Point Contact Switch USB Connector 365nm 395nm

Portable UV Curing System UV Curing Pen Point Contact Switch USB Connector 365nm 395nm

UV Spot Light Source UV Curing Pen is easy to handle, convenient to carry. Its wavelength has 365nm and 395nm.

Air Cooling Spot UV LED Lights for Fast Curing UV Glue

Air Cooling Spot UV LED Lights for Fast Curing UV Glue

UV LED Spoint curing machine is for fast curing UV glue only 1-5 seconds. The facility is using air cooling to shorten the attenuation of the lamp and increase the service life.

Spot UV LED UV Curing Pen is for fast curing UV glue only in 1-5s. Its irradiation head is designed for as a pen, convenient to install carriage in using.

Air Cooling Single Irradiation Head UV LED Spot Light Source

Air Cooling Single Irradiation Head UV LED Spot Light Source

Portable small UV LED Point Light Source Irradiation Machine, with a power controller host and an air cooling head, is easy to carry, light weight, high intensity. It takes only a few seconds to solidify the UV glue.