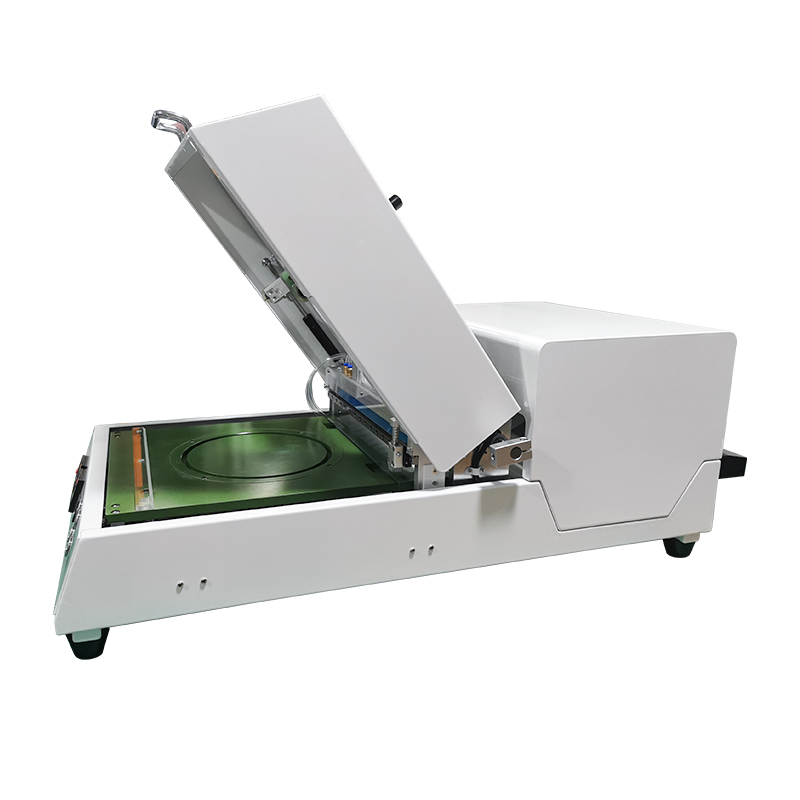

model no. :

DSXUV- Semi-auto-BGWM12port of dispatch :

ShenzhenPayment :

T/T 100% before shipmentoriginal region :

ChinaLead Time :

15-20days

Local features:

1. Suitable for BG film, UV film, and blue film;

2. Suitable for 12 inch wafer with iron ring for slicing

3. Easy to operate, adjustable blade cutting position;

4. The film has no cracks, no bubbles on the surface, no burrs on the edges, and no other abnormalities;

5. The main body is made of stainless steel and aluminum alloy, with reliable quality and stable performance;

6. The film has high precision and stability;

7. Simple operation, easy to understand and master;

8. The appearance of this machine is beautiful, sturdy and reliable, with superior performance and affordable price, which can greatly improve production efficiency for customers.

Tube size: diameter 8mm

Machine casing: white spray painted metal casing

Volume: length 1450 * width 650 * height 497mm

Net weight: approximately 150KG

Packing List:

1 machine

2. One power cord

3. One manual

4. One copy of warranty card and one copy of certificate of conformity

5. One circular cutting blade

6. One cross cutting knife

7. One catheter

Consumables for vulnerable parts

Round cutting blade

Cross cutting blade

Air duct

Solenoid valve

The Shenzhen Deshengxing Electronics semi-automatic wafer laminating machine has the following functions and advantages:

1. Film application accuracy: The semi-automatic wafer film application machine adopts advanced film application technology and precise alignment system, which can achieve high-precision film application operation, ensuring accurate alignment and bonding between the film material and the wafer.

2. Wafer size adaptability: The semi-automatic wafer laminating machine is suitable for various wafer size ranges and can handle wafers from small to large sizes, providing flexible usage options.

3. Operational convenience: The equipment is equipped with a user-friendly interface and control system, allowing operators to easily master and operate the equipment, reducing training costs and learning difficulties for operators.

In semi-automatic mode, operators can participate in some operations as needed, providing more flexible film selection.

5. High efficiency: The semi-automatic wafer laminating machine can quickly complete laminating tasks, improve production efficiency, shorten laminating cycles, and is suitable for situations that require efficient processing of small batches of wafers.

6. Safety: The equipment is equipped with safety features such as safety sensors and emergency stop buttons to ensure the safety of the operation process and reduce potential risks for operators.

7. Accessories and Accessories: The semi-automatic wafer laminating machine can be equipped with various accessories and accessories, such as laminating tools and laminating materials, to meet different laminating needs.

8. Reliability and stability: The equipment design has undergone strict engineering and quality control, with good reliability and stability, and can operate stably for a long time, reducing equipment failures and maintenance costs.

In summary, the semi-automatic wafer laminating machine has become an important equipment choice in wafer production and processing due to its high-precision laminating operation, wafer size adaptability, ease of operation, and safety. It can improve the quality and efficiency of film coating, providing reliable solutions for wafer manufacturing and the semiconductor industry.

Semiconductor Double Film Wafer Chip Laminating Machine

Semiconductor Double Film Wafer Chip Laminating Machine

Wafer Frame Film Mounter Machine can place UV tape and blue film at the same time for using.

Manual Wafer Laminating Machine Wafer Backgrinding Mounter 6 8 12 Inches

Manual Wafer Laminating Machine Wafer Backgrinding Mounter 6 8 12 Inches

6/8/12 inches Manual Wafer Laminator series is a fast and efficient sticking film machine, special designed for wafer, glass, LED PCB, and ceramic cutting process.

DSXUV-Wafer-M8 8 Inches Manual UV Tape Wafer Mounter

DSXUV-Wafer-M8 8 Inches Manual UV Tape Wafer Mounter

Wafer Frame Film Mounter is a machine that fixes a wafer and a ring together through a blue film or UV film.

DSXUV-Wafer-M6 6 Inches Semiautomatic Wafer Mounter For Dicing UV Film Cutting

DSXUV-Wafer-M6 6 Inches Semiautomatic Wafer Mounter For Dicing UV Film Cutting

Wafer Tape Laminating Machine is a machine that fixes a wafer and a ring together through a blue film or UV film.

Customized Glass Filter Semiconductor BG Film QFN Lamination Equipment

Customized Glass Filter Semiconductor BG Film QFN Lamination Equipment

DSXUV accept customized various glass material film laminating machine, various UV tape blue film BG film laminating systems.

Customized Plastic Ring Wafer Film Mounting Machine

Customized Plastic Ring Wafer Film Mounting Machine

DSXUV accept customized various glass material film laminating machine, various UV tape blue film BG film laminating systems.