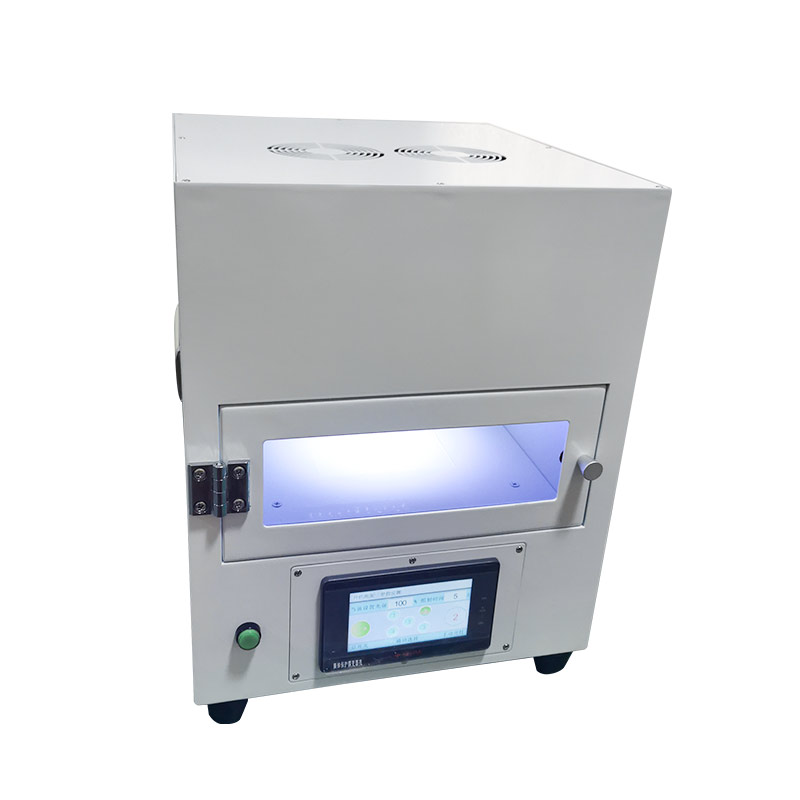

Nitrogen UV Curing System Tape Led,Compact and Practical UV Curing system, 5 seconds for The Film to Detach from The Wafer, Adjustable Time, Adjustable illumination, Nitrogen Protection

model no. :

DSXUV-100x100-N2Color :

Whiteport of dispatch :

ShenzhenPayment :

T/T before shipmentoriginal region :

ChinaLead Time :

10-15 days

The Nitrogen UV Curing Box is an equipment that performs UV curing process in an inert gas (nitrogen) environment, mainly used for efficient curing of photosensitive materials such as inks, coatings, adhesives, etc. Its core features and advantages are as follows:

Model

DSXUV100X100-N2

Shenzhen Deshengxing Electr

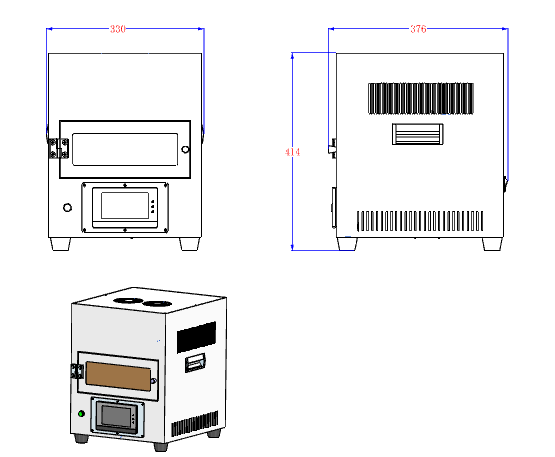

Size

L330*W376*H414mm

Gas

Nitrogen

Drawer capacity

115*115*100mm

Light source area

100X100mm

Wavelength

UVLED365nm /Other wavelengths can be customized

Power

300W

illuminance

10-600mW/cm2 adjustable

Voltage

100-240V AC 50-60HZ

Material

White sheet metal

Function

Adjustable time and illumination, 10% -100% adjustable

Illumination direction

Illuminate from top to bottom

Language

Touch screen/English

Factory

onics

Energy conservation and environmental protection

Low energy consumption: Rapid solidification reduces energy consumption, and nitrogen can be recycled to reduce gas consumption.

Ozone free production: A closed environment is used to prevent UV lamps from producing ozone, reducing pollution and health risks.

2、Core advantages of Nitrogen UV Curing system

Efficient curing performance

Eliminating oxygen blocking polymerization: The nitrogen environment reduces the interference of oxygen on free radical reactions, significantly improving the efficiency of deep and surface curing.

Shorten curing time: 30% -50% faster than traditional air environments, especially suitable for high crosslink density materials.

Improve surface quality

Anaerobic inhibition: avoids surface sticking, atomization and other defects after curing, achieving a high gloss and smooth coating effect.

Reduce bubbles: Inert environment reduces the risk of bubble formation from volatile substances.

6 Inches Dicing Wafer Frame Iron Hoop Semiconductor Fixed Cutting Ring SUS420J Material

6 Inches Dicing Wafer Frame Iron Hoop Semiconductor Fixed Cutting Ring SUS420J Material

6 inches Wafer Expander Rings is used for semiconductor packaging, film, cutting, adhesive process bearing appliances.

12 inches Wafer Frame Dicing Cutting Ring Round Fixed Silicon Disk Iron Ring For Wafer Blue Film

12 inches Wafer Frame Dicing Cutting Ring Round Fixed Silicon Disk Iron Ring For Wafer Blue Film

Stainless Steel 12'' Iron Ring Wafer Frame is strong hardness, resistance to bending, good stickiness, durability.

Customized 6 8 12 inch Crystal Iron Ring Wafer Cutting Film Hoop for Wafer Foundry

Customized 6 8 12 inch Crystal Iron Ring Wafer Cutting Film Hoop for Wafer Foundry

The selection material of Stainless Steel Wafer Iron Rings is through SGS certification, high bending strength, high hardness, can bear high load, high wear, corrosive media.

Nitrogen UV Curing Systems Multiple 6 inches Wafer Dicing Machine

Nitrogen UV Curing Systems Multiple 6 inches Wafer Dicing Machine

Curing multiple 6 inches UV Wafer at the same time, UV Film Tape Curing Systems reduce the adhesive strength of all UV-sensitive dicing tapes under controlled environment.

Customized UV LED Cold Light Source UV LED Exposure Unit 365nm 395nm

Customized UV LED Cold Light Source UV LED Exposure Unit 365nm 395nm

Professional Manufacturing UV Wafer Tape Curing Machine is low calorie, good bonding performance, fast speed, environmental protection equipment.

Clamshell 500*500mm UV Tape UV Curing Systems Reducing Blue Film Viscosity

Clamshell 500*500mm UV Tape UV Curing Systems Reducing Blue Film Viscosity

Adhesive strength becomes lower when UV(Ultraviolet light) is irradiated by UV Tape UV Curing Systems.