Equipped with nitrogen support rod, clamshell labor-saving function; Adjust the height of the working plate to rise, you can adjust the spacing between the DIE; Using the motor lifting and cylinder lifting to complete the membrane expansion process, to ensure the consistency of the membrane expansion;

model no. :

DSXUV-WFE-6Brand:

DSXUVport of dispatch :

Shenzhenoriginal region :

ChinaLead Time :

15days1, Parameter

1. Equipment technical parameters:

|

Name |

The wafer expansion machine |

Model |

DSXUV-WFE-6 |

|

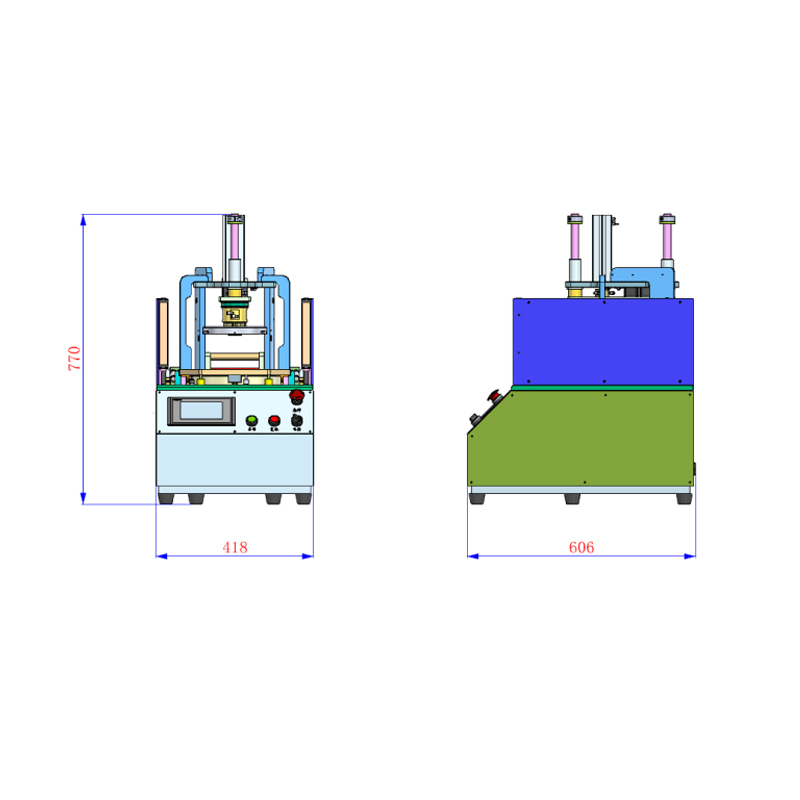

Equipment size |

L418*W606*770mm |

Adapt to product size |

4inch wafer |

|

rated voltage |

AC 220V |

frequency |

50/60HZ |

|

Rising height of working plate / tray heating temperature |

20-60mm/50-80℃ |

pressure |

0.5-0.8Mpa ,Factory setting is 0.6 Mpa |

|

Film type |

PO/PVC NITTO etc. |

Film thickness |

80-180um |

|

Cut the film way |

The knife tte automatically cuts the film |

Membrane expansion function |

Semi-Auto |

|

weight |

About 67 kg |

guarantee period |

New products, non-human damage, the whole machine Quality guarantee for one year |

| Wood Weight | 42KG |

|

1). The height and speed of the expanded film can be set numerically through the touch

screen;

2). Chuck has a constant temperature heating function, to contribute to the ductility of the

membrane;

3). Adjust the height of the working plate to rise, you can adjust the spacing between the DIE;

4). Optional on the round cutting automatic film cutting function;

5). Equipped with nitrogen support rod, clamshell labor-saving function;

6). 5-inch touch screen, display parameters, perform steps, fault alarm;

7). Using the motor lifting and cylinder lifting to complete the membrane expansion process,

to ensure the consistency of the membrane expansion;

8). Clip-cover automatic locking device;

Chip Film Transfer Molding Machine

Chip Film Transfer Molding Machine

Chip inversion machine can be used to transfer wafers from one film to another (such as UV film, blue film, optical film, etc.). This can be used to manufacture devices with specific functions, such as optical devices, sensors, and microelectronic components

6 8 12 inches Semiautomatic Wafer Expander

6 8 12 inches Semiautomatic Wafer Expander

Blue Film Crystal Expander is used for expanding wafers after the singulation/dicing process

Manual UV Tape Expander Machine Die Matrix Expander

Manual UV Tape Expander Machine Die Matrix Expander

Manual Type Semiconductor Wafer Expander is widely used in expanding UV film on the crystal ring to facilitate the next operation.

Standard 8inch Wafer Expander for LED Semiconductor Chip

Standard 8inch Wafer Expander for LED Semiconductor Chip

Semi-Automatic Wafer Film Expander is used to evenly stretch the tape after the cutting process.

Semiconductor Wafer Chip Grip Ring Plastic Hoops Rings for Wafer Handling

Semiconductor Wafer Chip Grip Ring Plastic Hoops Rings for Wafer Handling

Plastic Wafer Expander Rings can be used in semiconductor and LED chip, consisted of inner and outer ring.

6inch Semiautomatic Wafer Expander for UV Tape Blue Film Expansion

6inch Semiautomatic Wafer Expander for UV Tape Blue Film Expansion

6 inch Semi-automatic Die Matrix Expander is widely used in wafer UV tape blue film expansion, frame ring to hoop ring, customized.