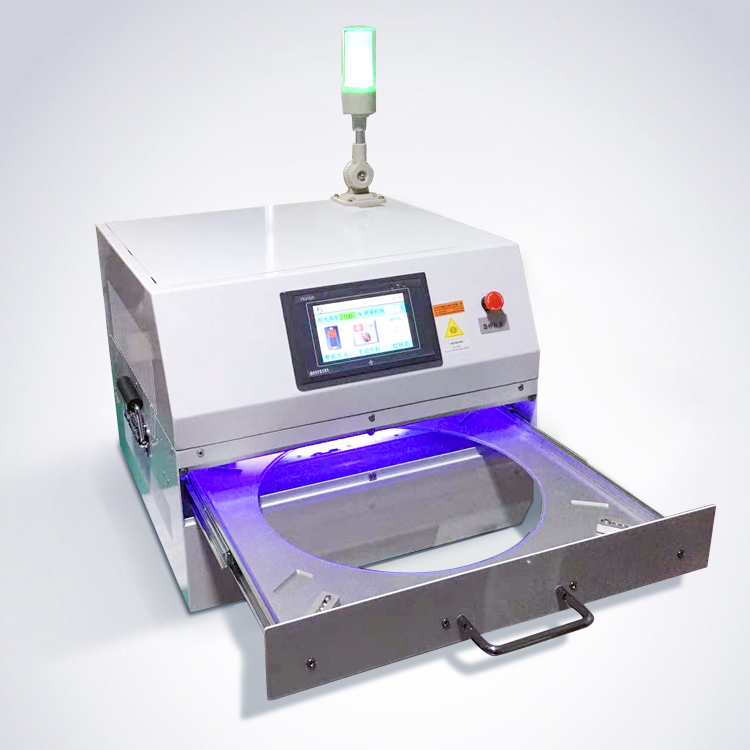

DSXUV 12inch Semi-automatic Wafer Mounter Film Sticking Machine

This equipment (lamator) is mainly used for 12 inch Si wafer BG film coating. No burrs, no bubbles. The wafer type is dummy wafer. This semi-automatic film sticking machine is suitable for applying film to products such as wafers, semiconductors, ceramics, and glass. It is a device used for film coating processing, specifically designed to precisely adhere thin film materials to the surface of wafers. It combines the characteristics of manual operation and automatic control, providing higher film application accuracy and efficiency while maintaining operational convenience.