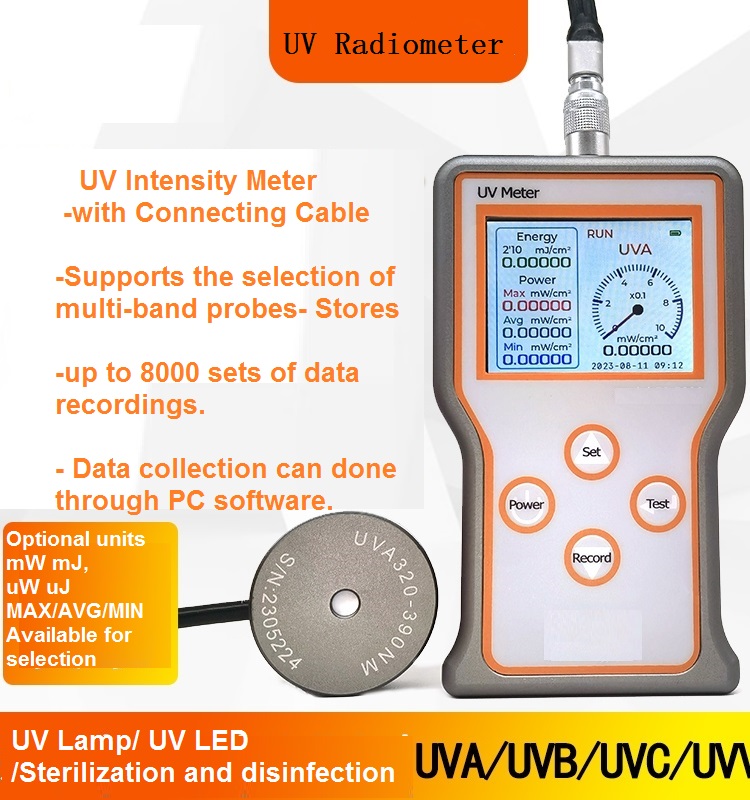

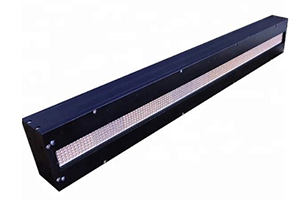

The DSXUVUV strength Meter 5800 series is widely used in various industries in the UV field. It offers multiple options for selecting different UV wavelengths and can measure real-time power, peak power, average power, minimum power, and energy value of UV light sources. It allows users to test different regions of UV light sources and evaluate their uniformity. The instrument is designed for simp...

continue reading

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español Nederlands

Nederlands العربية

العربية български

български svenska

svenska

+8618924372460

+8618924372460 live:1651063690jennifer

live:1651063690jennifer uvcure@uvspacelight.com

uvcure@uvspacelight.com 0086-18924372460

0086-18924372460