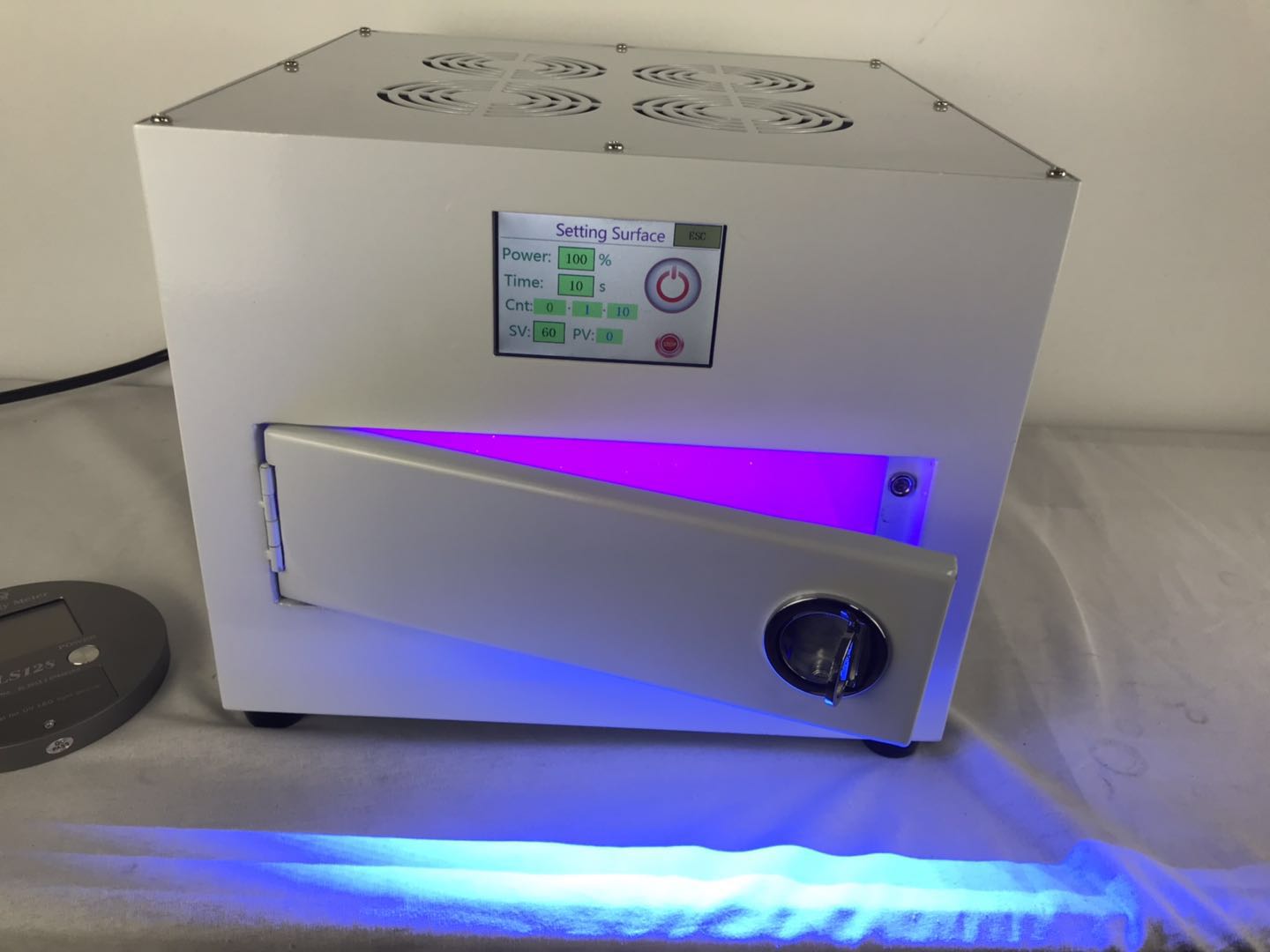

385nm UV Oven is for 3D printing curing. Closed UV Curing Box do not leak light and is used imported 385nm UV LED Light Beads.

model no. :

385nm UV Curing ChamberBrand:

DSXUVport of dispatch :

SHENZHENPayment :

T/T 100% Before Shipmentoriginal region :

CHINA

385nm UV Oven is for 3D printing curing. Closed UV Curing Box do not leak light and is used imported 385nm UV LED Light Source.

Advantages of 385nm UV Curing Chamber :

Fast curing, good effect

No light leakage, no harm to the body

385nm UV Oven Parameters :

|

Model |

DSXUV-OVEN-200150 |

Manufacturer |

Shenzhen Deshengxing Electronics Co., Ltd. |

|

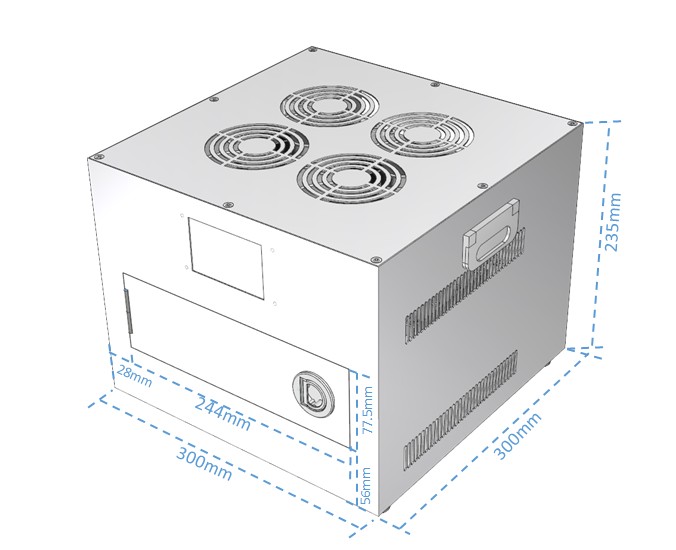

Dimensions |

L300*W300*H2 3 5mm |

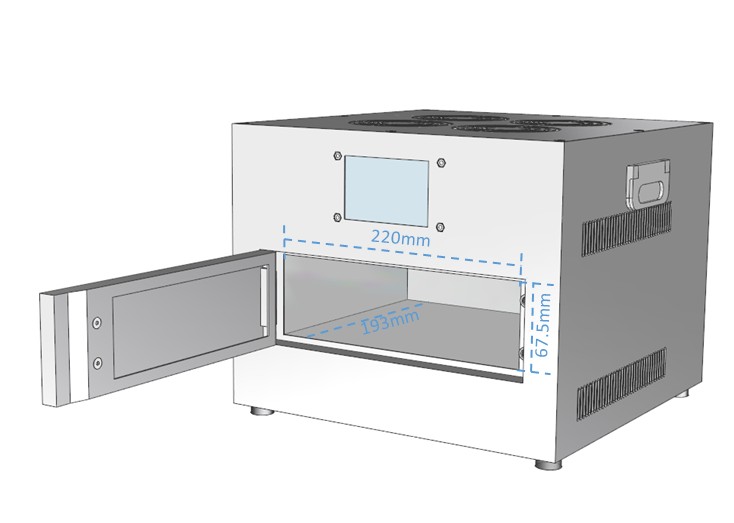

Light output area |

200 * 150 mm |

|

Cooling |

Air Cooling |

Power Input |

100-240V AC 50-60HZ |

|

Power |

420 W |

wavelength |

365nm-420nm optional |

|

Drawer capacity |

L244*W193*H67.5mm |

Illuminance |

> 500 mW / cm2 70mm at EIT Test |

|

Material / Weight |

White gold paint / About 15Kg White Sheet Metal |

Display /Language |

LCD Touch Screen |

|

Function |

Adjustable time, intensity, mode Time, intensity, mode adjustable |

LED Cumulative Time |

Record accumulated using time |

|

RS232 Serial Communication |

Can query and adjust intensity, time and mode |

Control Method |

Connected with MCU, PLC and other automatic equipment to control and feedback the work state |

Application areas of UV Curing Chamber :

Microelectronics Industry - UV Light Curing Applications

1 , mobile phone component assembly (camera lens, earpiece, microphone , housing , LCD module , touch screen coating, etc.)

2 , hard disk head assembly (gold wire fixing , bearing , coil , die bonding, etc.)

3 , DVD / digital camera (lens , lens bonding, circuit board reinforcement)

4 , motor and component assembly (wire , coil fixed, coil end fixed , PTC / NTC component bonding , protection transformer core)

5 , semiconductor chip (moisture protection coating , wafer mask , wafer contamination inspection , UV tape exposure , wafer polishing inspection)

6 , sensor production (gas sensors, photoelectric sensors, fiber optic sensors, photoelectric encoders, etc.)

7, 3D printing curing

PCB industry UV LED Exposure Box application

1 , components (capacitors , inductors , various plug-ins , screws , chips, etc.) fixed

2 , moisture-proof potting and core circuit, chip protection , antioxidant coating protection

3 , circuit board type (corner) coating

4 , ground wire , flying wire , coil fixed

5 , wave soldering through hole mask

Medical device UV Light Curing System application

UV glue bonding makes economical automated assembly of medical devices easier. Nowadays , the advanced LED UV light source system , which can cure solvent-free UV glue for a few seconds , as well as the dispensing system , makes an effective and economical method for consistent and repetitive bonding of medical device assembly processes. The optimization and control of UV light sources is very important for the manufacture of reliable medical devices. The use of UV-curable glue offers many advantages , such as lower energy requirements , saving cure time and location , increasing productivity and making automation easier. UV glue is commonly used to bond and seal medical devices that require very high quality and best reliability. UV glue curing Typical applications are in the medical device assembly , such as the need bond 1) of different material ( or different mechanical properties ) 2) material is not thick enough , can not use the soldering method 3 ) pre-production of sub-parts. .

1 , anesthesia mask 2 , syringe 3 , catheter 4 , intravenous infusion tube 5 , vascular implant accessories 6 . Endoscope 7 , arterial positioning 8 , tubular drainage device 9 , tracheal tube 10 , blood oxygenator 11 , hearing aid 12 , detection , monitoring , and imaging equipment 13 , biochip 14 , bonding PVC, thermoplastic ( polycarbonate) Fat and ABS)

Optical Industry - ST-UVLED Light Curing Applications

1 . Optical component assembly (lens group , prism , optical engine assembly)

2 . Image instrument assembly (microscope , endoscope , infrared , night vision , probe, etc.)

Optical communication industry UVLED light curing application

1 . Passive components (wavelength division multiplexer WDM, array grating waveguide AWG, optical splitter SPLITTER, optical isolator ISOLATOR, optical coupler COUPLOR, etc.) , various glass package structure bonding or potting , fixing of small components Wait.

2 . Active devices (coaxial devices TOSA/ROSA/BOSA, VCSEL , laser collimators, etc.), especially FTTX low-cost miniaturized plastic package structures

3 . Fiber optic cable (overcoat , marking , bonding, fiber optic gyroscope)

Research and Institute - ST-UVLED Light Curing Application

1. Polymer chemistry ( nano coating , photocurable resin , photosensitizer , monomer , UV ink, etc. )

2 , medical polymer materials ( medical plastics , catheters ), microorganisms

3 , photochemistry ( photocatalysis , photoexcitation , photosynthesis, etc. )

4 , semiconductor ( light accelerated etching , cutting , uv tape, etc. )

New Design Portable LED UV Curing Oven for 3D Printing

New Design Portable LED UV Curing Oven for 3D Printing

New Design box-style portable UV Curing Box furnace instead of traditional mercury lamp UV dryer.

100*100mm Customized UV Oven Ultraviolet LED Curing Machine

100*100mm Customized UV Oven Ultraviolet LED Curing Machine

Enclosed 100x100mm UV Curing Oven is widely used in mobile phone shell, CD, film switch, electronic plastic shell UV surface paint coating.

Customized High Power UV LED Masking System Manufacturer

Customized High Power UV LED Masking System Manufacturer

UV LED Masking System can be used for electronics, PCB board and chip, optical lens fixed layer, speakers, DVD bald, computer wire connector, medical industrial and other application fields.

UV Masking Exposure System for Wafer Samples

UV Masking Exposure System for Wafer Samples

UV Masking Exposure System for Wafer Samples is a Very compact table-top system, perfectly monochromatic at 365nm, hard and soft contact up to 4 inches wafer.

Factory Price LED Curing Box UV Ink Curing Oven UV Chamber

Factory Price LED Curing Box UV Ink Curing Oven UV Chamber

LED Curing Box UV Ink Curing Oven UV Chamber is instantaneous curing, no ozone, environment protection, energy conversation, no mercury.

Drawer Type MINI Curing Oven UV Curing Chamber

Drawer Type MINI Curing Oven UV Curing Chamber

Drawer Type MINI Curing Oven UV Curing Chamber is a miniature ultraviolet curing machine, can cure micro motor, LCD, LCM, camera module, atc..