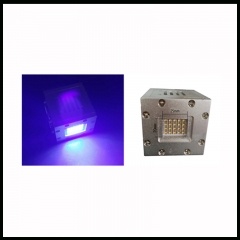

Rectangular 365nm Ultraviolet Curing Light Source for Crack Bonding, irradiation area 360*20mm, greatly reduce the power consumption of traditional mercury lamp, but also reduce the complexity of installing UV curing lamps.

model no. :

UV Ink Curing Light SourceBrand:

DSXUVport of dispatch :

SHENZHENPayment :

T/Toriginal region :

CHINA

UV Ink is used as the base material of the light curing resin as the ink. Under the irradiation of ultraviolet light, the free radical is produced by the photo-initiator, which causes the base material polymerization and the photocrosslinking reaction to solidify the ink.

UV Glue is selectively absorbed by the photon, and its drying is affected by the total energy of the emitted light of UV light source and the distribution of light energy of different wavelengths. Under the irradiation of UV light, the photo-polymerization initiator of UV ink absorbs a certain wavelength of photons and triggers the excitation state to form free radicals or ions. Then, through the transfer of energy between molecules, the polymeric prepolymer and photosensitive monomer are transformed into excited states, which produce charge transfer complexation. These complexes are constantly crosslinked and solidified into membranes.

The Characters of Linear 365nm UV Ink Curing Machine Without Ozone :

1.Instantly curing, high production efficiency.

2.No volatile solvent. There will be no solvent erosion and damage to print; Will not pollute the human body and environmental protection.

3.The ink concentration is stable, and it will not be cause by the difference of concentration.

4.Ink does not dry out, solvent-free stench.

5.The light curing speed is extremely fast, and the UV equipment is small and occupies little space.

6.The heat emitted of UV light does not cause damage to the hot print.

7.Transparent or semi-transparent ink, hardening speed and color effect.

Parameters of Ultra High Power UV Light-Curing Equipment Curing UV Ink :

|

Technical Data of the UV Irradiation Light Head: |

|

|

Wavelength(±5nm) |

365nm/385nm/395nm/405nm |

|

Curing Area |

Other Sized Available |

|

Electronic Power |

800w |

|

Input voltage |

90-260VAC 50Hz / 60Hz |

|

Cooling method |

Water cooling |

|

Life |

>10000H |

|

Conveyor Speed |

100-400mm Adjustable |

|

Irradiation distance |

10-100mm adjustable |

|

Optic power |

800mw/cm2 (10mm irradiation distance) |

|

Recommend Irradiation Distance |

10-100mm |

|

Irradiation Area |

360*20mm |

|

Size of Irradiation Head |

400*38*55mm |

|

Weight |

2kg |

Air Cooling UV Solidify Machine Curing Mobile Phone Touch Screen

Air Cooling UV Solidify Machine Curing Mobile Phone Touch Screen

Air Cooling UV Solidify Machine, Emitting Window:104*25mm, is designed as a simple, low cost, small form factor air-cooled UV LED curing lamp for pinning and curing of inks, coatings and adhesives, mobile phone touch screen.

104*25mm Water Cooling UV LED Curing System

104*25mm Water Cooling UV LED Curing System

The WnnexCureTM EB168 UV Light Emitting Diode provides highest output power in an extremely medium mechanical package for high speed pinning and full cure applications. The EB168 UV LED Light Source is CE, RoHS, and REACH compliant.

Top Quality 365nm UV LED Curing Equipment Drying UV Glue

Top Quality 365nm UV LED Curing Equipment Drying UV Glue

100*100mm high power top quality power saving 365nm LED UV Curing Machine Curing UV Glue can be customized. You know 365nm is the best wavelength to cure UV glue.

365nm LED UV Curing UV Glue UV Curing Machine for Bonding

365nm LED UV Curing UV Glue UV Curing Machine for Bonding

Customized 365nm UV LED Curing System for lens bonding. UV LED Area Curing System can make glue curing, wavelength 365nm, rec area : 20*25mm, quickly, effective to cure.

Bar Type LED UV Curing System for UV Ink Use to Cure

Bar Type LED UV Curing System for UV Ink Use to Cure

Energy Saving Bar Type LED UV Curing System, This kind of UV LED curing system can be used for curing UV ink, UV varnish and UV paint and is suitable for flex printer, offset printer, flatbed printer and flexo printer.

High Power UV LED Dryer for UV Adhesive Curing System 30*120mm

High Power UV LED Dryer for UV Adhesive Curing System 30*120mm

High Power UV LED Dryer for UV Adhesive Curing System is 30*120mm, 365nm.