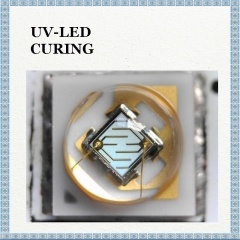

SVC CUN66A1B 3W UV LED 3535 365nm series are designed for high current operation and high power output applications.It incorporates state of the art SMD design and low thermal resistant material.SVC CUN66A1B 3W UV LED 3535 365nm is ideal UV light source for curing, printing, and detecting applications.

Product Parameters:

Brand: Korea SVC

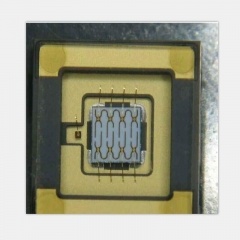

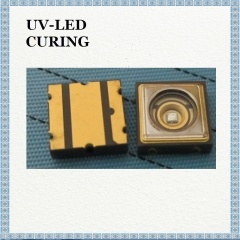

Type:CUN66A1B

Size:3.5*3.5mm

Wavelength:360-370nm

Radiant Flux:1000-1300mW

Forward Current/Forward Voltage:1400mA/3.0-4.4V

View Angle:55deg.

Lens:Silicon

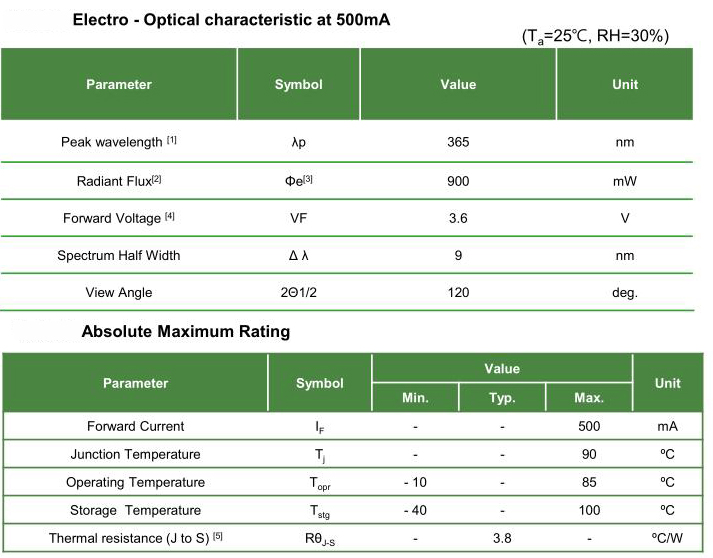

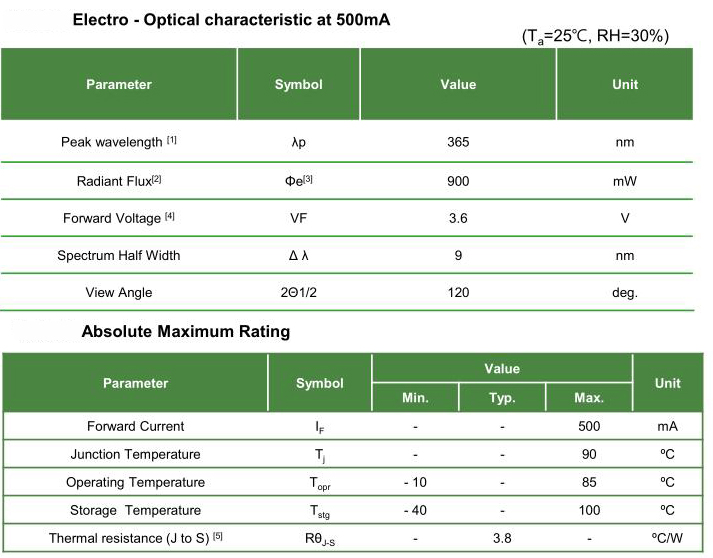

Performance Characteristics

Notes :

1. Peak Wavelength Measurement tolerance : ±3nm

2. Radiant Flux Measurement tolerance : ± 10%

3. Φ e is the Total Radiant Flux as measured with an integrated sphere.

4. Forward Voltage Measurement tolerance : ±3%

5. Rθ J-S is the thermal resistance between chip junction to solder.

The PCB is made of aluminum and the size of PCB is 2.5cm by 2.5cm

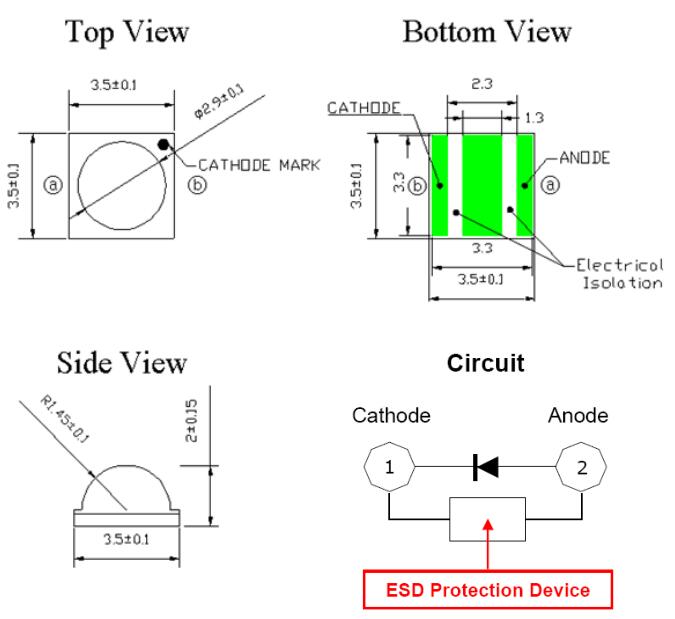

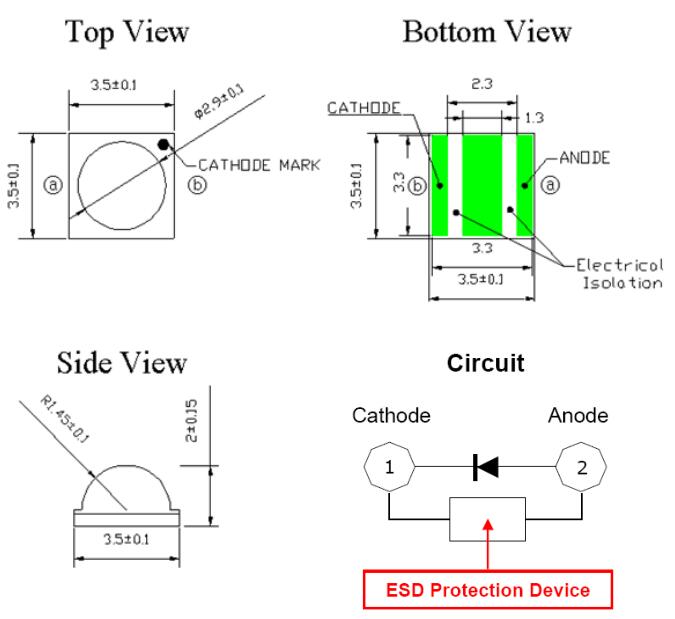

Mechanical Dimensions

(1) All dimensions are in millimeters.

(2) Scale : none

(3) Undefined tolerance is ±0.2mm

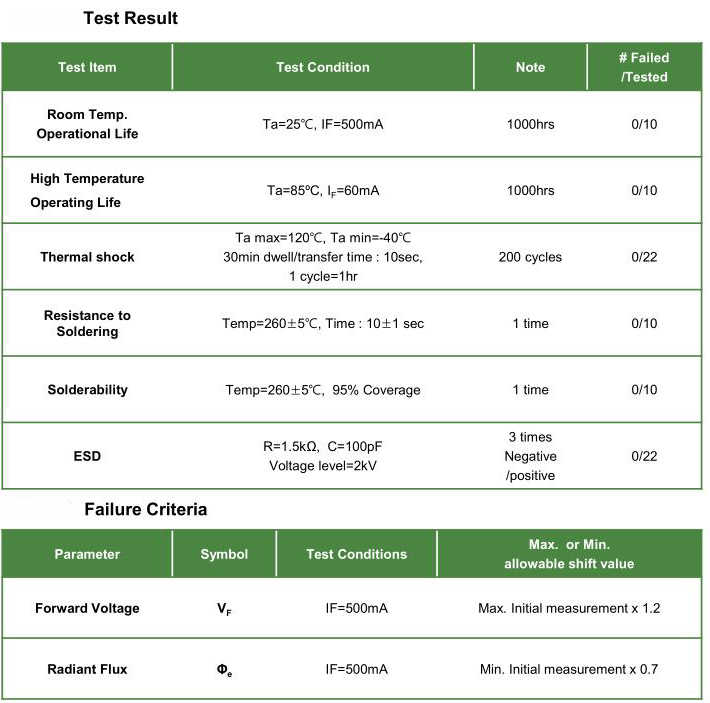

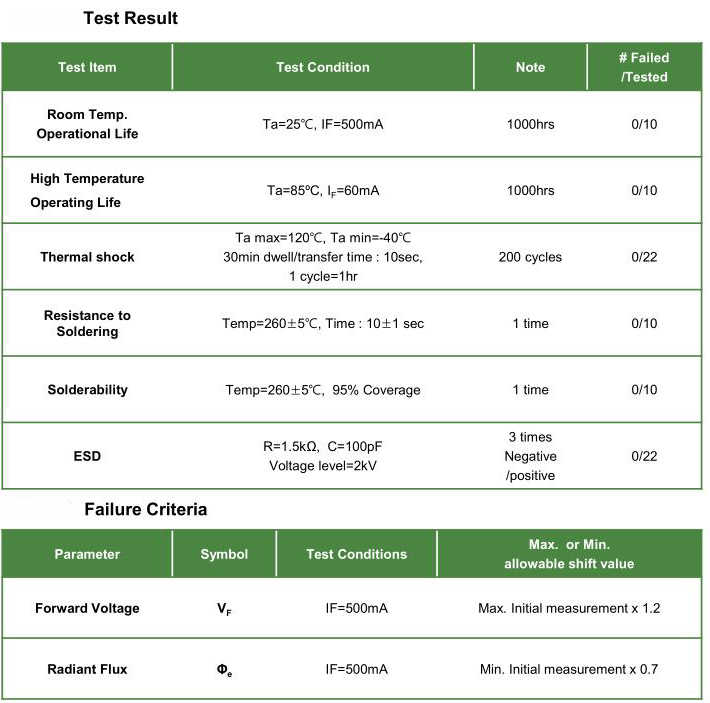

Reliability Test

Notes :

The value is measured after the test sample is cooled down to the room temperature.

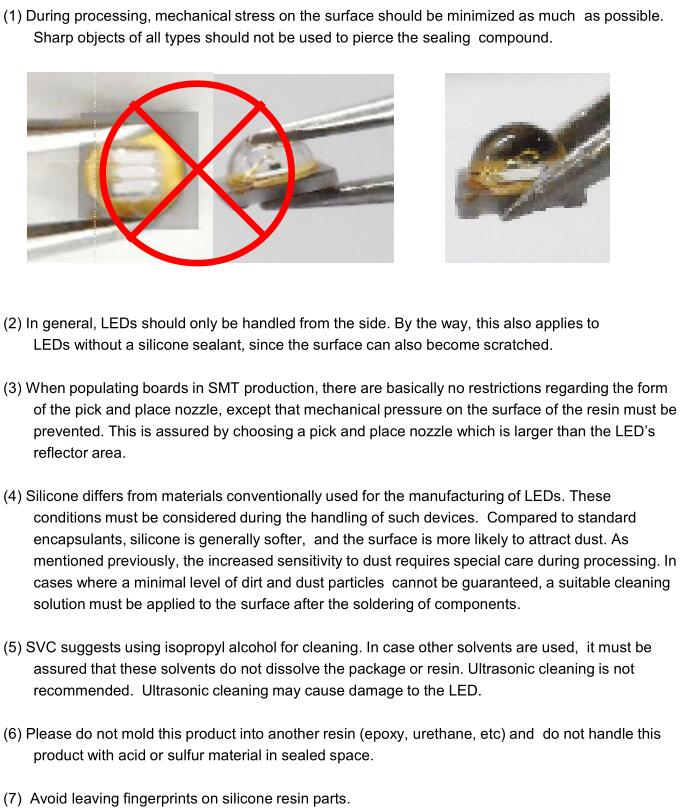

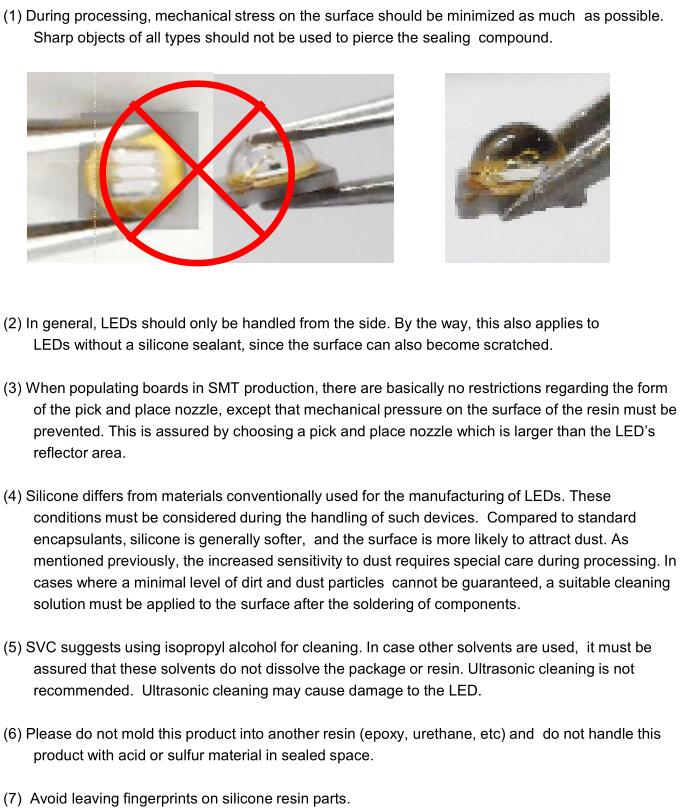

Handling of Silicone Resin for LEDs

Precaution for Use

(1) Storage

To avoid the moisture penetration, we recommend storing LEDs in a dry box with a desiccant . The

recommended storage temperature range is 5℃ to 30℃ and a maximum humidity of RH50%.

(2) Use Precaution after Opening the Packaging

Use proper SMD techniques when the LED is to be soldered dipped as separation of the lens may

affect the light output efficiency.

Pay attention to the following:

a. Recommend conditions after opening the package

- Sealing / Temperature : 5 ~ 30℃ Humidity : less than RH60%

b. If the package has been opened more than 4 weeks (MSL 2a) or the color of

the desiccant changes, components should be dried for 10-24hr at 65±5℃

(3) Do not apply mechanical force or excess vibration during the cooling process to normal

temperature after soldering.

(4) Do not rapidly cool device after soldering.

(5) Components should not be mounted on warped (non coplanar) portion of PCB.

(6) Radioactive exposure is not considered for the products listed here in.

(7) This device should not be used in any type of fluid such as water, oil, organic solvent and etc.

When washing is required, IPA (Isopropyl Alcohol) should be used.

(8) When the LEDs are in operation the maximum current should be decided after measuring the

package temperature.

(9) LEDs must be stored in a clean environment. We recommend LEDs store in nitrogen-filled

container.

(10) The appearance and specifications of the product may be modified for improvement without

notice.

(11) VOCs (Volatile organic compounds) emitted from materials used in the construction of fixtures ca

n penetrate silicone encapsulants of LEDs and discolor when exposed to heat and photonic energy. T

he result can be a significant loss of light output from the fixture. Knowledge of the properties of the m

aterials selected to be used in the construction of fixtures can help prevent these issues.

(12) The slug is electrically isolated.

(13) Attaching LEDs, do not use adhesives that outgas organic vapor.

(14) The driving circuit must be designed to allow forward voltage only when it is ON or OFF. If the rev

erse voltage is applied to LED, migration can be generated resulting in LED damage.

(15) LEDs are sensitive to Electro-Static Discharge (ESD) and Electrical Over Stress (EOS). Below is

a list of suggestions that Seoul Viosys purposes to minimize these effects.

a. ESD (Electro Static Discharge)

Electrostatic discharge (ESD) is the defined as the release of static electricity when two objects come

into contact. While most ESD events are considered harmless, it can be an expensive problem in

many industrial environments during production and storage. The damage from ESD to an LEDs may

cause the product to demonstrate unusual characteristics such as:

- Increase in reverse leakage current lowered turn-on voltage

- Abnormal emissions from the LED at low current

The following recommendations are suggested to help minimize the potential for an ESD event.

One or more recommended work area suggestions:

- Ionizing fan setup

- ESD table/shelf mat made of conductive materials

- ESD safe storage containers

One or more personnel suggestion options:

- Antistatic wrist-strap

- Antistatic material shoes

- Antistatic clothes

Environmental controls:

- Humidity control (ESD gets worse in a dry environment)

b. EOS (Electrical Over Stress)

Electrical Over-Stress (EOS) is defined as damage that may occur when an electronic device is

subjected to a current or voltage that is beyond the maximum specification limits of the device.

The effects from an EOS event can be noticed through product performance like:

- Changes to the performance of the LED package

(If the damage is around the bond pad area and since the package is completely encapsulated

the package may turn on but flicker show severe performance degradation.)

- Changes to the light output of the luminaire from component failure

- Components on the board not operating at determined drive power

Failure of performance from entire fixture due to changes in circuit voltage and current across total

circuit causing trickle down failures. It is impossible to predict the failure mode of every LED exposed

to electrical overstress as the failure modes have been investigated to vary, but there are some

common signs that will indicate an EOS event has occurred:

- Damaged may be noticed to the bond wires (appearing similar to a blown fuse)

- Damage to the bond pads located on the emission surface of the LED package

(shadowing can be noticed around the bond pads while viewing through a microscope)

- Anomalies noticed in the encapsulation and phosphor around the bond wires.

- This damage usually appears due to the thermal stress produced during the EOS event.

c. To help minimize the damage from an EOS event Seoul Viosys recommends utilizing:

- A surge protection circuit

- An appropriately rated over voltage protection device

- A current limiting device

High Power UV-LED NVSU333A U365nm 18.9W 3640mW/cm2

High Power UV-LED NVSU333A U365nm 18.9W 3640mW/cm2

NICHIA UV LED NVSU233B U365nm

NICHIA UV LED NVSU233B U365nm

NICHIA NCSU033B 365nm UV LED

NICHIA NCSU033B 365nm UV LED

NICHIA UV LED NCSU033C U365nm

NICHIA UV LED NCSU033C U365nm

SVC CUN6GF1A UV 365nm 5W High Radiant Flux 1300mW

SVC CUN6GF1A UV 365nm 5W High Radiant Flux 1300mW

High Power NICHIA UV LED NCSU276A U365nm for UV Curing

High Power NICHIA UV LED NCSU276A U365nm for UV Curing