The applications of LG 365nm UV LED 45 Degree Viewing Angle Curing UV Glue are for UV Curing, UV Ink Curing, Photo-Catalyst, Sensor Light, etc..

model no. :

365nm UV LED 45° for UV Glue CuringBrand:

LGport of dispatch :

SHENZHENPayment :

T/Toriginal region :

CHINALead Time :

The Smae DayLG 365nm UV LED 45 Degree Viewing Angle Curing UV Glu erequires unique and delicate production process and places strict controls from wafer manufacturing to final inspection.

Features of LG 365nm Ultraviolet Light :

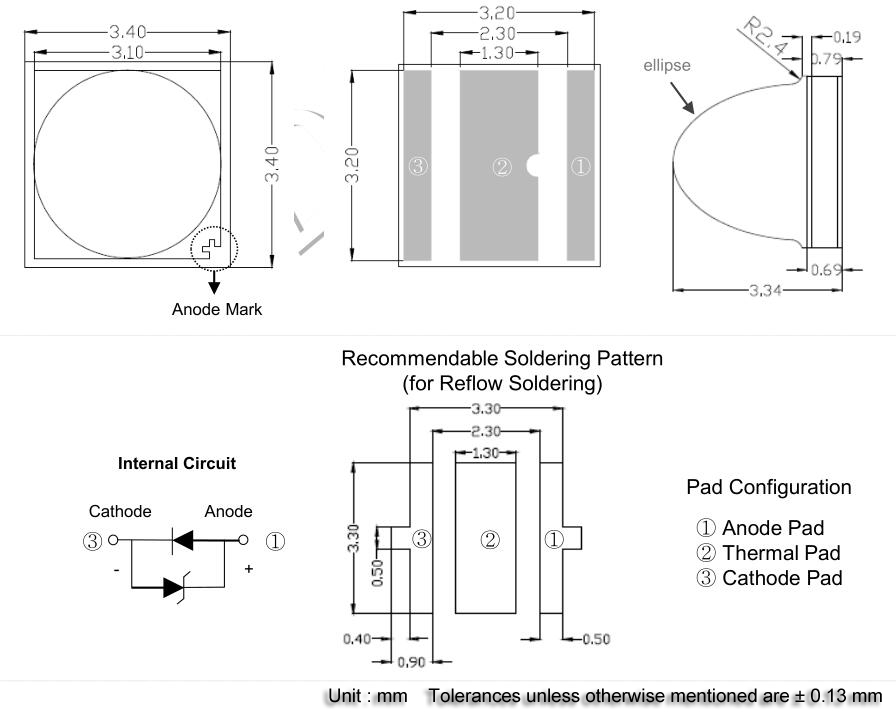

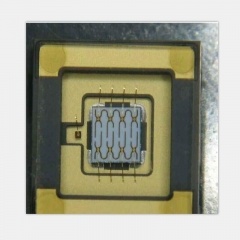

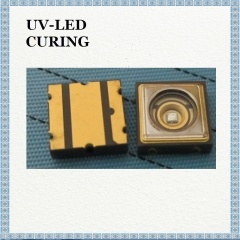

- Surface Mount Type : 3.40×3.40×3.34 (L×W×H, Unit : mm)

- Viewing Angle(Directivity) : Typical 45°

- Soldering Methods : Pb-Free IR-Reflow Soldering

Outline Dimensions of Professional UV Curing Light :

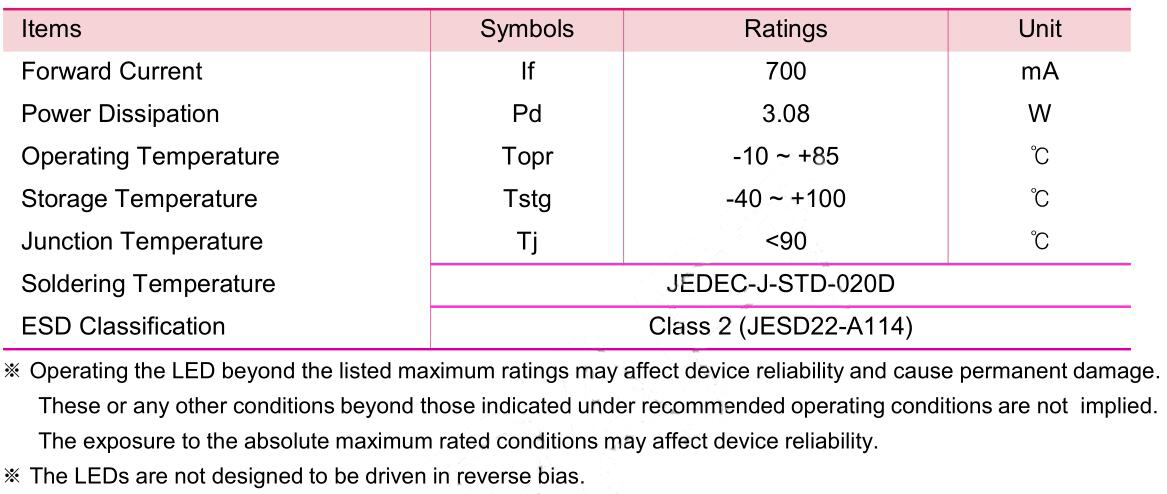

Absolute Maximum Ratings of LG 365nm UV LED :

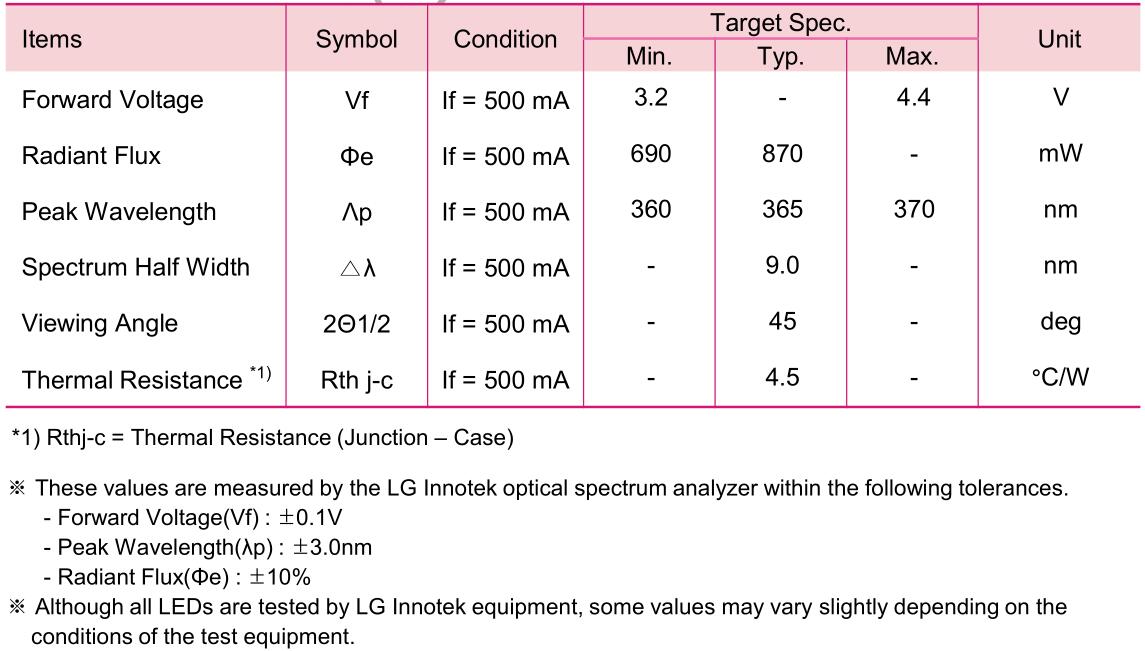

Electro-Optical Characteristics of High Power 365nm UV Curing Light :

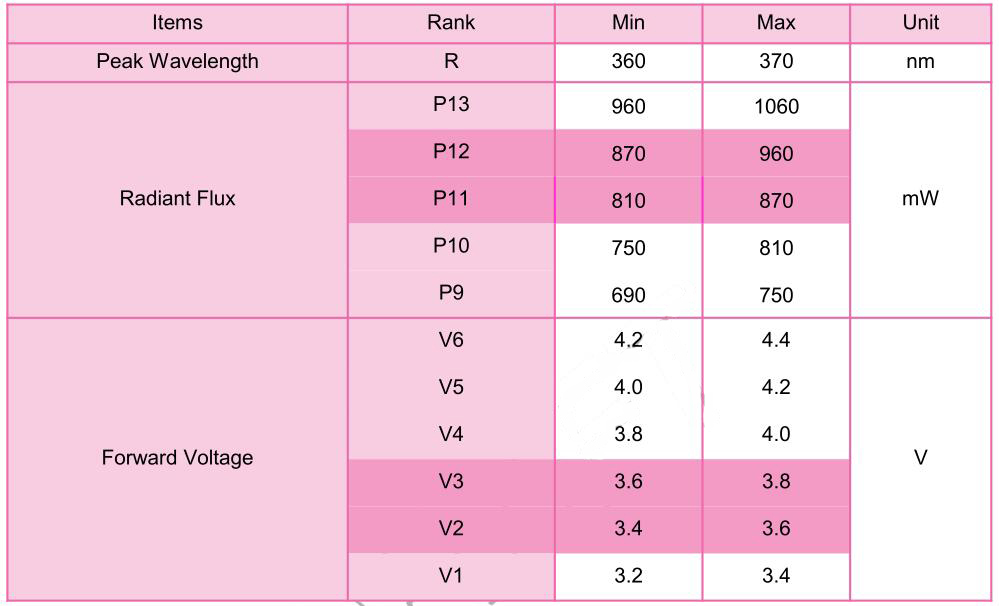

Bin Structures of 45 Degree Viewing Angle UV LED :

※ Forward Current = 500mA

※ Rank name method : Please refer to the following example

Rank Name : R-P11-V2

- Peak Wavelength = R

- Radiant Flux = P11

- Forward Voltage = V2

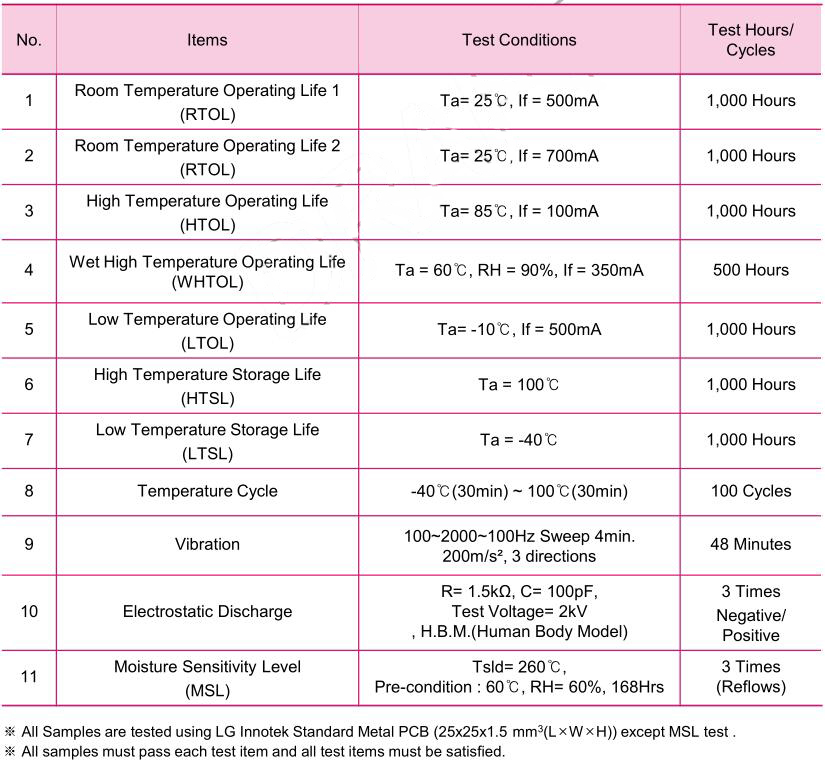

Reliability Test Items and Conditions of LG 365nm UV LED :

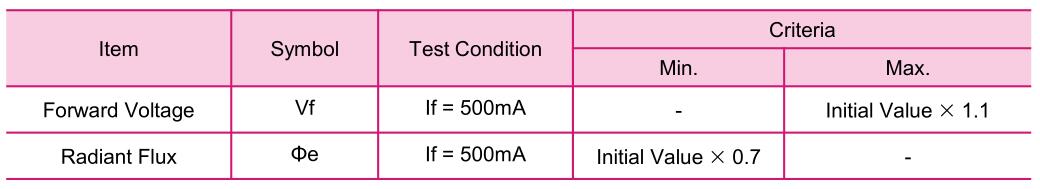

Failure Criteria

Reliability Test

Cautions on Use 365nm UV Curing Light :

1.Moisture-Proof Package-. The moisture in the SMD package may vaporize and expand during soldering.

-. The moisture can damage the optical characteristics of the LEDs due to the encapsulation.

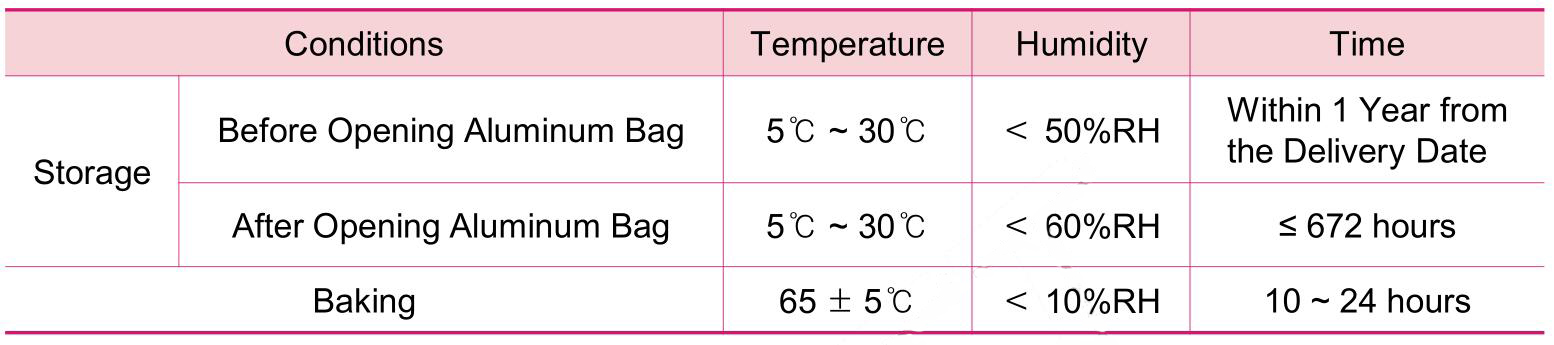

2. During Storage

3. During Usage

-. The LED should avoid direct contact with hazardous materials such as sulfur, chlorine, phthalate, etc..

-. The metal parts on the LED can rust when exposed to corrosive gases. Therefore, exposure to corrosive gases must be avoided during operation and storage.

-. The silver-plated metal parts also can be affected not only by the corrosive gases emitted inside of the end-products but by the gases penetrated from outside environment.

-. Extreme environments such as sudden ambient temperature changes or high humidity that can cause condensation must be avoided.

4. Cleaning

-. Do not use brushes for cleaning or organic solvents (i.e. Acetone, TCE, etc..) for washing as they may damage the resin of the LEDs.

-. Isopropyl Alcohol(IPA) is the recommended solvent for cleaning the LEDs under the following conditions.

Cleaning Condition : IPA, 25℃ max. × 60sec max.

-. Ultrasonic cleaning is not recommended.

-. Pretests should be conducted with the actual cleaning process to validate that the process will not damage the LEDs.

5. Thermal Management

-. The thermal design of the end product must be seriously considered, particularly at the beginning of the system design process.

-. The generation of heat is greatly impacted by the input power, the thermal resistance of the circuit boards and the density of the LED array combined with other components.

6. Static Electricity

-. Wristbands and anti-electrostatic gloves are strongly recommended and all devices, equipment and machinery must be properly grounded when handling the LEDs, which are sensitive against static electricity and surge.

-. Precautions are to be taken against surge voltage to the equipment that mounts the LEDs.

-. Unusual characteristics such as significant increase of current leakage, decrease of turn-on voltage, or non-operation at a low current can occur when the LED is damaged.

7. Electrostatic Discharge (ESD)

- The LEDs are sensitive to static electricity or surge voltage and current. The Electrostatic Discharge can damage a LED Chip. Also, It can be affect a reliability belong to the life time of LED package. When handling LEDs, the following measures against ESD are actively recommended :

1) Please wear a wrist strap, anti-static clothes, foot wear and gloves.

2) Please set up a grounded or anti-static paint floors, a grounded or the ability to surge protection

-workstation equipment and tools.

3) ESD protection- worktable/bench, mat made of a conductive materials.

- An appropriate grounding is required for all devices, equipment, and machinery used in product

assembly. Please apply surge protection after review when designing of commercial products(Curing Module, etc.).

- If tools or equipment contain insulating materials such as glass or plastics, the following measures against ESD are strongly recommended :

1) Dissipating static charge with conductive materials

2) Preventing charge generation with moisture

3) Plug in the ionizing blowers(ionizer) for neutralizing the charge

- The customer is advised to check if the LEDs are damaged by ESD when performing the characteristics inspection of the LEDs in the application. Damage of LED can be detected with a forward voltage checking(measuring) at low current(≤1mA).

- ESD damaged LEDs may have a current flow at a low voltage.

* Failure Criteria : Vf < 2.0V at If = 0.5mA.

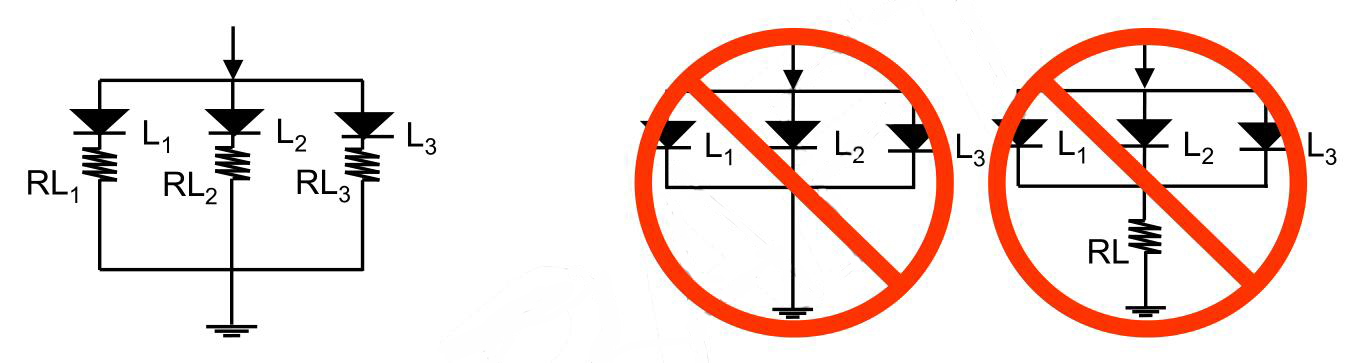

8. Recommended Circuit

-. The current through each LED must not exceed the absolute maximum rating when designing the circuits.

-. In general, there can be various forward voltages for LEDs. Different forward voltages in parallel via a single resistor can result in different forward currents to each LED, which also can output different luminous flux values. In the worst case, the currents can exceed the absolute maximum ratings which can stress the LEDs. Matrix circuit with a single resistor for each LED is recommended to avoid the luminous flux fluctuations.

Fig.1. Recommended Circuit in Parallel Mode :

Separate resistors must be used for each LED.

Fig.2. Abnormal Circuit :

Avoid this circuits! The current through the LEDs may vary due to the variation in LED forward voltage.

-. The driving circuits must be designed to operate the LEDs by forward bias only.

-. Reverse voltages can damage the zener diode, which can cause the LED to fail.

-. A constant current LED driver is recommended to power the LEDs.

High Power UV-LED NVSU333A U365nm 18.9W 3640mW/cm2

High Power UV-LED NVSU333A U365nm 18.9W 3640mW/cm2

NVSU333A UV-LED is widely used in high precision curing, ink curing (printing), bill checker etc. It's also the best way to solidify UV glue.

NICHIA UV LED NVSU233B U365nm

NICHIA UV LED NVSU233B U365nm

NICHIA UV LED NVSU233B U365nm is most applied in UV curing, splicing, UV glue, and UV prinying ink curing.

NICHIA NCSU033B 365nm UV LED

NICHIA NCSU033B 365nm UV LED

NICHIA NCSU033B 365nm UV LED can be used for criminal investigation, such as the observation of fingerprint, bloodstain, etc., mineral fluorescence observation, oil cleaning observation, and so on.

NICHIA UV LED NCSU033C U365nm

NICHIA UV LED NCSU033C U365nm

NICHIA UV LED NCSU033C U365nm is Pb-free reflow Soldering application, built-in EDS protection Device, RoHS compliant.

SVC CUN6GF1A UV 365nm 5W High Radiant Flux 1300mW

SVC CUN6GF1A UV 365nm 5W High Radiant Flux 1300mW

The applications of SVC CUN6GF1A UV 365nm 5W High Radiant Flux 1300mW are UV curing, printing, coating, adhesive, counterfeit dection/security, UV torch, fluorescence, photegraphy, dental curing, crime inspection, oil leak detection.

High Power NICHIA UV LED NCSU276A U365nm for UV Curing

High Power NICHIA UV LED NCSU276A U365nm for UV Curing

NICHIA UV LED NCSU276A U365nm requires unique and delicate production process. NICHIA places strict controls from wafer manufacturing to final inspection.