LED Copper Based Plate Board Led Heatsink Thermal Separation Led Lamp Lase For 10pcs 3535 Cree XPE XTE XPG LED DIY

model no. :

SMD UV LED Copper SubstrateBrand:

DSXUVport of dispatch :

ShenzhenPayment :

T/T 100% before shipmentoriginal region :

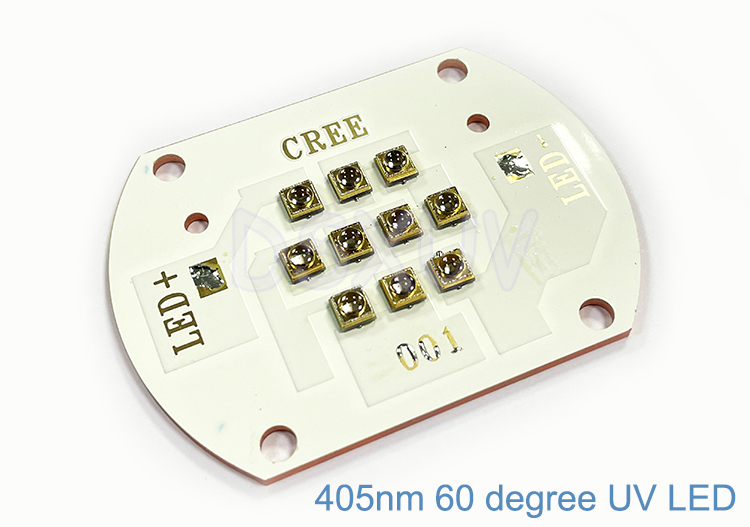

ChinaUV LED Curing Light Source Copper Based Plate is used with 10pcs SMD 3535 LED, all connection in series

Parameters:

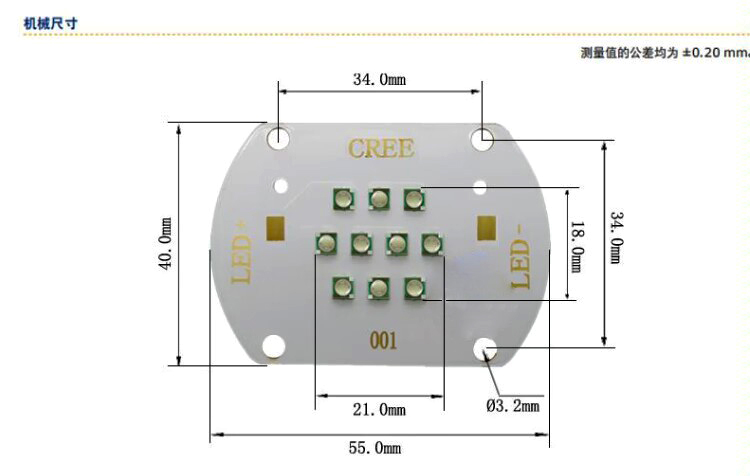

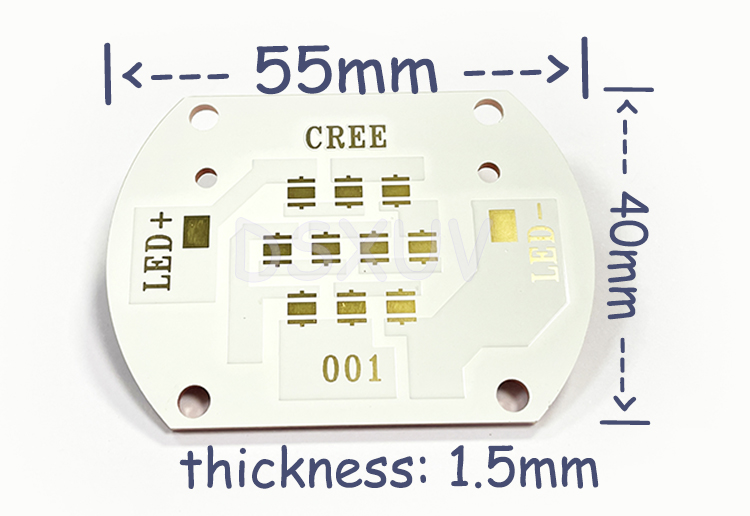

Size of PCB: L55*W40*H1.5mm

Material: copper substrate

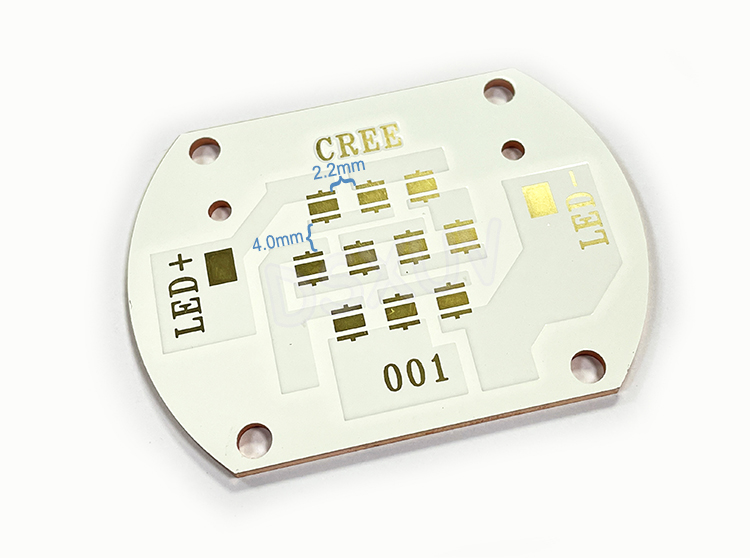

Size of LED: crosswise 2.2mm, lengthways 4.0mm

Right LED: 3pins, UV 3535 LED (like CREE, XPE, XTE, OSRAM, white light, etc.)

Cautions:

1.If you are not sure if your LED is working, please take a photo and send it to customer service to confirm.

2.When using the drive power supply, be sure to ensure that the LED is fully connected to the power supply before powering on. Do not connect LED lights on power, which is very dangerous and also east to burn LED lamp beads, serious, lamp beads may be directly burnout.

3.All LED beads can not be used for a long time with the battery. The correct way is to refer to the second point. The power drive must be a constant current power supply.

4.All the substrate only plays the role of heat conduction, and cannot completely have good heat dissipation function. When used, it is necessary to install additional cooling system, air cooling or water cooling.

5.Self welding basic knowledge: control the temperature and time. Proper selection and use of low temperature tin and thermal grease.

6.Welded substrate of our company will be tested OK and lit up before delivery. If the light is on, it is normal. DSXUV shall not be liable for any human factors. The lamp beads is blackened and the lamp is not worked due to the over-current, the gold wire is fused, and the lamp has bad cooling, belonging to human causes.

(here is a picture for reference, if you need the UVLEDs, please contact customer service)

16mm PCB Aluminum Base Plate for 2835 UV LED

16mm PCB Aluminum Base Plate for 2835 UV LED

This type of 16mm Printed Circuit Board is suitable for 2835 LED light beads.

Three LEDs in Parallel 20mm PCB Printed Circuit Board Matched with 3535 Lights

Three LEDs in Parallel 20mm PCB Printed Circuit Board Matched with 3535 Lights

This is the type for welding three 3535 LEDs in parallel 20mm Copper Base Board, which is appropriate for all 3535 LED light beads.

NICHIA 3535 Copper Base PCB UV Spot Light Chip

NICHIA 3535 Copper Base PCB UV Spot Light Chip

NICHIA's two new lamp beads NCSU276A and NVSU233A can be equipped with a dedicated copper substrate. Nissan 3535 is tailor-made for copper substrates, for flshlight,laboratory,etc..

NCSU033B UV LED Point Light Source Thermoelectric Separation Copper Substrate

NCSU033B UV LED Point Light Source Thermoelectric Separation Copper Substrate

The NCSU033B Thermoelectric Separation Copper Substrate is a dedicated substrate for the UV LED spot light irradiation head.

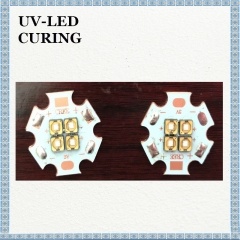

CUN6GF1A 365nm Four Lights a Group Copper Substrate

CUN6GF1A 365nm Four Lights a Group Copper Substrate

CUN6GF1A 365nm 4 series 12V copper specifications: 20mm *1.5mm High brightness curing.

NICHIA Dedicated Copper Substrate for NCSU033B NVSU333A

NICHIA Dedicated Copper Substrate for NCSU033B NVSU333A

NICHIA dedicated copper substrate. Off-the-shelf NCSU033B copper board, NC4U133B copper board, NVSU333A copper board, size 20*1.6mm.