UV Integrator 140 UV Energy Meter measures the spectral range of 250-410nm (nanometer), and the optimal induced UV wavelength is 365nm (nanometer).

model no. :

Ultraviolet Integrator DetectionBrand:

DSXUVport of dispatch :

ShenzhenPayment :

T/T 100% Before Shipmentoriginal region :

ChinaRUNWING Energy Meter 140 is a high quality, high precision UV energy meter. Type 140 energy meter is our patented product (special No. : 200630307499.7). its special built-in handle design makes it more convenient to use and is also one of the characteristic that distinguishes it from other band of UV energy meter.

RUNWING UV Integrator 140 UV Energy Radiometer is used to measure the irradiation energy of different light sources under certain conditions. It is an extremely important curing quality instrument in the UV production process, and an essential tool to control and achieve good curing quality consistency of products.

The UV energy meter measures the spectral range of 250-410nm (nanometer), and the optimal induced UV wavelength is 365nm (nanometer).

For each use, please set the switch of the instrument to the position of “ON”, and the reading displayed ON the LCD screen is “0”mJ/cm2. if it is not for special purpose, please reset the reading to zero before each measurement.

If your process is particularly required, you can also make repeated measurements. After each measurement, the reading does not need to be reset to zero. Then, the last reading displayed on the instrument will be the cumulative value of many repeated measurements.

When the measurement is completed, the switch should be adjusted to the “off” position so that the instrument can be turned OFF in time. Correct operation will effectively extend the battery life of the instrument.

Parameters of U250-410nm UV Energy Tester :

1.Spectrum : UV 250-410nm

2.Light intensity : 0-5000mW/cm2

3.Energy : 0-999999mJ/cm2

4.Power supply : AAA battery

5.Power consumption : 100uA

6.Battery life : one year under normal operating conditions

7.Dimension : disc structure, diameter is 140mm, height is 13mm

8.Weight : 450g

9.Ambient temperature : 0 to 45℃

10.Temperature duration : continuous irradiation not exceeding 10s at 110℃

11.Calibration period : as all electronic components, such as sensors, usually age over time, a one-year calibration period is recommended to ensure more accurate measurement accuracy and effectiveness.

12.Warranty period : within one year from the date of purchase, expect for man-made damage or damage caused by objective factors.

Usage of UV Integrator 140 Joule Measurement :

1.Turn the witch ON the right side of the energy meter to the ON position and the digital “o” mJ/cm2 will be displayed ON the screen.

2.To prepare the measurement, turn the back of the energy meter towards the UV light source to ensure the effectiveness of the measurement.

3.When the UV energy detected has been recorded after the instrument has been exposed to the light source for a certain period of time, the energy value, corresponding to mJ/cm2, can be read from the display screen on the front of the instrument.

4.Each time a new instrument is made, the instrument is turned off as needed and then turned on again. The display will be reset to “0” mJ/cm2. You can then follow these steps to continue.

Cautions of UV Integrator Detector Meter :

1.Please avoid shaking or breaking the instrument by force.

2.After each measurement, please turn off the instrument and put it back in the box for safe-keeping.

3.When measuring, please do not look directly at the UV light source, to avoid exposure to strong light on exposed skin.

4.When measuring, please avoid putting the LED screen on the front of the instrument in strong light or high heat environment.

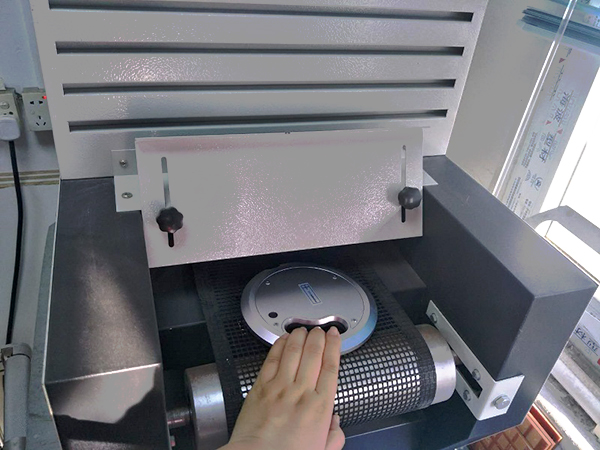

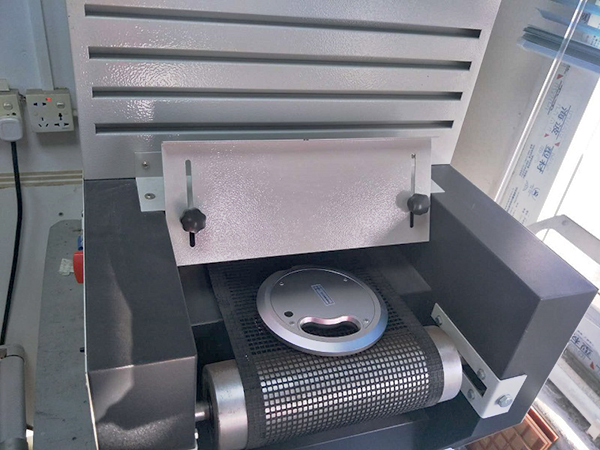

Application demonstration :

RUNWING UV Integrator provides an example of how to operate a UV energy meter by measuring a conveyor belt UV curing device. It details how to properly use a UV energy meter, a UV joule meter, a UV tester.

1. First of all, please confirm that the UV energy Tester is within its validity period. The normal annual calibration period is 1 year. If the validity period has been exceeded, it is recommended that you complete the calibration before using it in order to obtain accurate measurement data. As for our product, please contact us, we will have professionals to provide you with services and reasonable suggestions.

2. The second step is to start and light the ultraviolet lamp of the equipment and confirm that it reaches a stable working state. At this time, it is ready to start measurement. Take the UV energy meter out of the special package, please not the following :

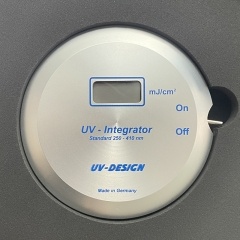

Front logo and structure : the appearance is disc type with a diameter of 14cm. The basic logo includes LED screen, unit of energy value, model logo, on/off logo and brand logo (Type RUNNING 140, which does not have RUNNING brand logo when it leaves the factory, only model “Integrator 140”)

Turn ON the UV energy meter : turn OV/OFF to the state of “ON”. At this time, the LCD will display a reading of “0”.

3. The third step is to lay the back side of the UV energy radiometer, namely the side with photosensitive window, on the conveyor belt facing the irradiation direction of the UV light source, so as to ensure that the photosensitive window can be normally sensitized. The effective value that can be directly displayed on the LED screen can be converted through the logic calculation inside the instrument.

Usually in this step, you need to be careful, remember not to mistakenly operate the front side, that is, the side with LED screen, and put into the UV room for exposure. Due to the different power of UV equipment / UV machine, the number of light sources is different, usually in the emitting of strong UV light at the same time will also produce a stronger IR thermal effect, that is, UV indoor environment temperature rise. If the LCD is mistakenly placed in a high-light and high-heat environment, the direct radiation of UV (ultraviolet) and IR (infrared) may cause damage to the device of the instrument.

4. The fourth step is to take off the UV Integrator energy meter measurement at the other end of the transmission belt, that is, the discharging mouth, and try not to exert too much force as far as possible, so as to avoid causing friction between the surface and conveyor belt, and scratching the display screen and the instrument shell, which will affect the reading and perception.

5. The fifth step is to read the data correctly. Visually inspect the front of the instrument to make sure that the upper and lower direction is correct when you read. The LCD screen is located on the top, and the data read is actually detected.

6. The sixth step is, if you just want get every measurement values, rather than the two above the accumulative energy value, please at the start of the next measuring instrument before action will reset. The specific operation is, adjust the ON/OFF to “OFF” state, stay for 3 seconds, until there is no data on the LCD screen display, you can reopened.

7. The seventh step is, if you are aware of the surface temperature of the instrument by the time you finish using it, please let it cool down before putting it into the packaging box.

The above is for your reference only, please use and operate according to the correct method, in order to give full play to the true function of the UV tester, and provide data guarantee for your process.

UV-DESIGN UV Integrator 140 High Temperature Resistance Ultraviolet Energy Measuring Instrument

UV-DESIGN UV Integrator 140 High Temperature Resistance Ultraviolet Energy Measuring Instrument

The Standard UV INT 140 Integrator is a high quality UV measuring instrument, measuring an integral in the spectral range from 250-410nm, with a peak at the area of 330nm.

Original Binding 250nm-410nm UV INT 150 UV-Integrator Radiometer

Original Binding 250nm-410nm UV INT 150 UV-Integrator Radiometer

UV 150 Integrator Radiometer is very small size round shape UV-Integrator, for measuring UV dose (mJ/cm2), diameter 90 mm only, height 12 mm, various spectral ranges available.

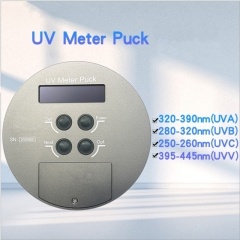

UV Meter Puck Testing UVA UVB UVC UVV Illumination Power Detector

UV Meter Puck Testing UVA UVB UVC UVV Illumination Power Detector

UV Meter Puck can measure four UV wavelength values through the same UV process. The default wavelength is UVA (320-395nm), UVB (280-320nm), UVC (250-260nm), UVV (395-445nm).

LS129 On-line Real-time Monitoring of UV Energy Value Illuminometer

LS129 On-line Real-time Monitoring of UV Energy Value Illuminometer

LS129 UV Illuminance Measurement is an intelligent UV digital probe, with communication functions, can direct-Connect PLC, Man-machine interface, PC and so on. Mainly used for on-line monitoring of ultraviolet intensity.

Short-Wave Measurement Deep UVC UV Radiaometer for Mercury Lamp Tube

Short-Wave Measurement Deep UVC UV Radiaometer for Mercury Lamp Tube

The product of Short-Wave Deep UV Illumination Meter is exclusively used in detecting ultraviolet UVC wave spectrum irradiation value.

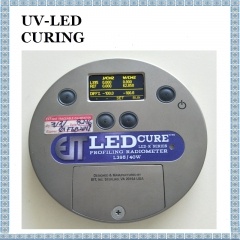

EIT LEDCure Radiometers UV Energy Meter Measure the Energy Generated

EIT LEDCure Radiometers UV Energy Meter Measure the Energy Generated

EIT LEDCure Radiometers, Accurately Measure the Energy Generated is highly accurate readings run-to-run, very repeatable unit-to-unit matching, absolute values when evaluating different sources.