Industrial grade UV online tester UV sensor, high-precision radiometer, real-time monitoring RS485 communication, UV energy meter probe

model no. :

DSXUV-5900Color :

Whiteport of dispatch :

ShenzhenPayment :

100% before shipmentoriginal region :

ChinaLead Time :

3 daysRS485 communication interface

MODBUS communication protocol

Real time monitoring of energy/power/temperature

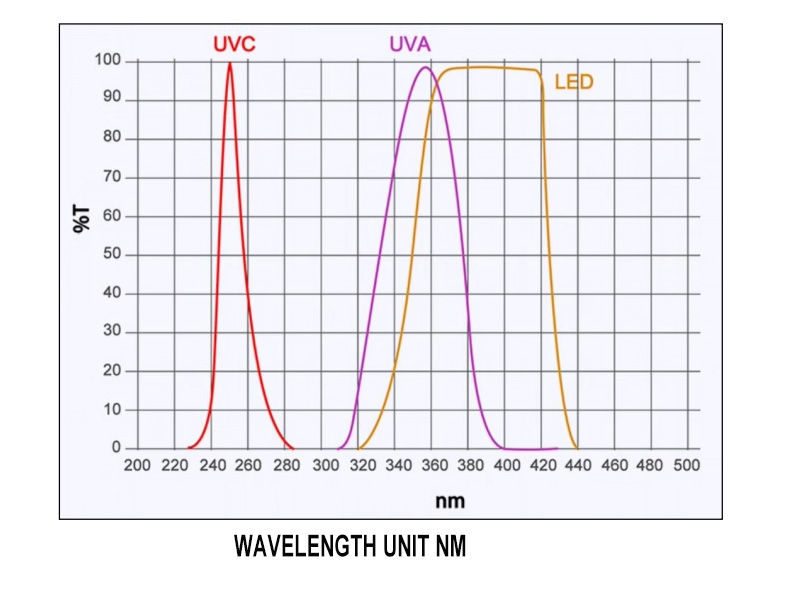

LED probe (340nm-420nm),UV curing, UV LED surface light source intensity and energy measurement

UVA probe (320nm-390nm),UV curing, high-pressure mercury lamp intensity and energy measurement

UVC probe (230-280nm),254nm, Measurement of intensity and energy of ultraviolet sterilization mercury lamp

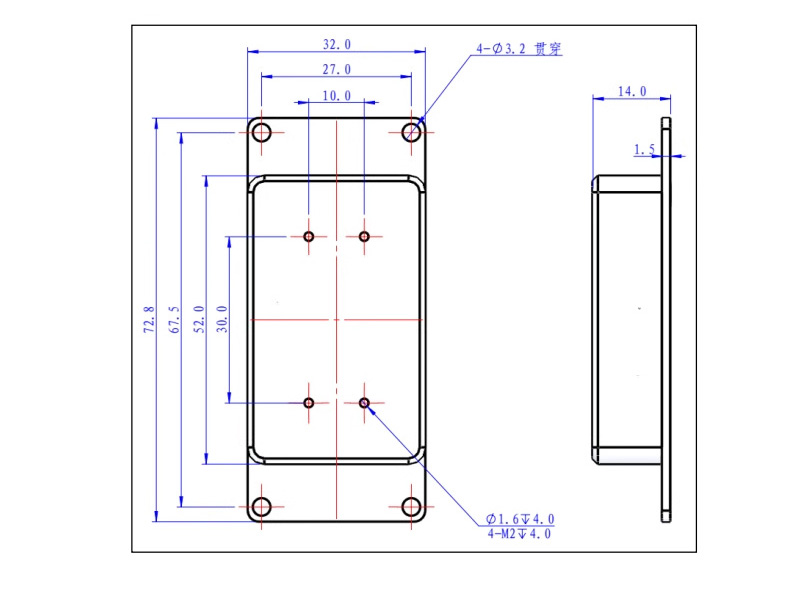

Controller size diagram:

Communication parameters:

1. Station number

This UV digital probe supports the standard MODBUS protocol, with a default communication address of "1". The probe address can be modified through the "Human Machine Interface Debugging Tool" or communication protocol. The address setting range is 1-247

2. Baud rate

The baud rate of the UV digital probe is 9600bps, which can be modified through the human-machine interface debugging tool or communication protocol. The available baud rates are:

4800,9600,19200,38400,57600,115200,230400,460800,921600

3. Communication protocol

Supports standard MODBUS protocol, which can read probe measurement data and set communication address and baud rate through communication protocol. For detailed communication commands, please refer to "UV Digital Probe Communication Protocol"

Measurement and precautions:

1. The probe receiving window is directly facing the ultraviolet light source to obtain the power density of ultraviolet radiation energy at the current testing point

2. Avoid contact with radioactive materials and stay away from high humidity environments

3. It is recommended that the inspection cycle be one year

4. Due to the sensitivity of UV probes to humidity changes, the storage environment is crucial. Long term use of this instrument. Please make sure to keep the probe in a low humidity environment. For example, keep the probe in a dry plastic bag.

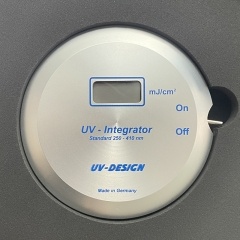

UV-DESIGN UV Integrator 140 High Temperature Resistance Ultraviolet Energy Measuring Instrument

UV-DESIGN UV Integrator 140 High Temperature Resistance Ultraviolet Energy Measuring Instrument

The Standard UV INT 140 Integrator is a high quality UV measuring instrument, measuring an integral in the spectral range from 250-410nm, with a peak at the area of 330nm.

Original Binding 250nm-410nm UV INT 150 UV-Integrator Radiometer

Original Binding 250nm-410nm UV INT 150 UV-Integrator Radiometer

UV 150 Integrator Radiometer is very small size round shape UV-Integrator, for measuring UV dose (mJ/cm2), diameter 90 mm only, height 12 mm, various spectral ranges available.

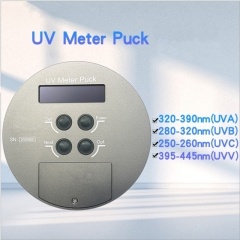

UV Meter Puck Testing UVA UVB UVC UVV Illumination Power Detector

UV Meter Puck Testing UVA UVB UVC UVV Illumination Power Detector

UV Meter Puck can measure four UV wavelength values through the same UV process. The default wavelength is UVA (320-395nm), UVB (280-320nm), UVC (250-260nm), UVV (395-445nm).

LS129 On-line Real-time Monitoring of UV Energy Value Illuminometer

LS129 On-line Real-time Monitoring of UV Energy Value Illuminometer

LS129 UV Illuminance Measurement is an intelligent UV digital probe, with communication functions, can direct-Connect PLC, Man-machine interface, PC and so on. Mainly used for on-line monitoring of ultraviolet intensity.

Short-Wave Measurement Deep UVC UV Radiaometer for Mercury Lamp Tube

Short-Wave Measurement Deep UVC UV Radiaometer for Mercury Lamp Tube

The product of Short-Wave Deep UV Illumination Meter is exclusively used in detecting ultraviolet UVC wave spectrum irradiation value.

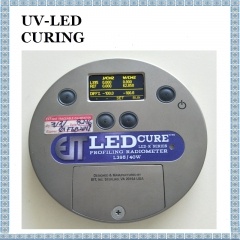

EIT LEDCure Radiometers UV Energy Meter Measure the Energy Generated

EIT LEDCure Radiometers UV Energy Meter Measure the Energy Generated

EIT LEDCure Radiometers, Accurately Measure the Energy Generated is highly accurate readings run-to-run, very repeatable unit-to-unit matching, absolute values when evaluating different sources.