LED UV curing systems for reducing the adhesive strength of UV sensitive dicing tapes, effective UV 365nm, holds wafers up to 310mm

model no. :

UV Dicing Tape Cure MachineBrand:

DSXUVport of dispatch :

ShenzhenPayment :

T/T 100% before shipmentoriginal region :

ChinaBuilt to cure wafers up to Φ310mm size, providing 365nm wavelength, ozone free UV irradiation source, timer and status indicator, DSXUV UV LED curing system can make the UV-sensitive tape curing and hardening to reduce its adhesive strength in seconds.

Compared to conventional mercury-arc lamps, it utilizes high-capability LEDs. It enables to process a variety of materials at maximum production speeds and homogeneous illumination, with low-input power requirements.

Open the cover and insert the wafer to the glass pane. Close the lid. The exposure will start immediately. Curing is complete after about 10-60 seconds, yielding a consistent throughput of 50 to 180 wafers/hour. The intensity can be adjustable.

Long term research and development, production of various specifications of UV LED Curing Systems, DSXUV support customized multiple wafer LED UV curing system machine.

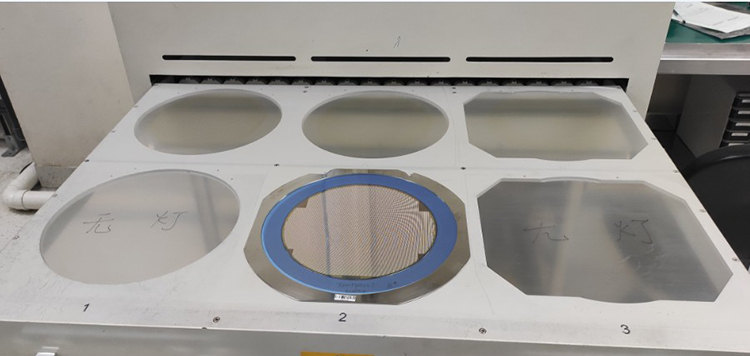

Features of multiple channel UV curing systems:

1.Multiple sizes of wafer crystal rings can be placed at the same time, including 6/8/12 inches and other customized sizes

2.Multi-channel design, can simultaneously debonding, also can independently debonding

3.Curing illumination and energy percentage adjustment function, illumination can be adjusted

4.Time to adjust

5.Prompt function after curing

6.It still use ultraviolet radiation from the bottom up the irradiation way, UV radiation directly to the UV film, avoid radiation damage to the wafer crystal element.

7.The enclosed curing light source has no effect on the human body.

8.Ultraviolet for LED packaging form, is no preheating and save time

9.Imported UV LED light source, service life is over 20000 hours

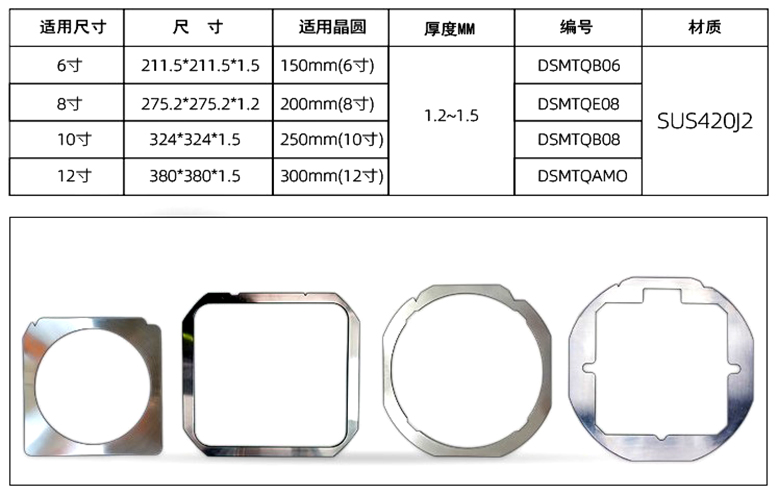

6 Inches Dicing Wafer Frame Iron Hoop Semiconductor Fixed Cutting Ring SUS420J Material

6 Inches Dicing Wafer Frame Iron Hoop Semiconductor Fixed Cutting Ring SUS420J Material

6 inches Wafer Expander Rings is used for semiconductor packaging, film, cutting, adhesive process bearing appliances.

12 inches Wafer Frame Dicing Cutting Ring Round Fixed Silicon Disk Iron Ring For Wafer Blue Film

12 inches Wafer Frame Dicing Cutting Ring Round Fixed Silicon Disk Iron Ring For Wafer Blue Film

Stainless Steel 12'' Iron Ring Wafer Frame is strong hardness, resistance to bending, good stickiness, durability.

Customized 6 8 12 inch Crystal Iron Ring Wafer Cutting Film Hoop for Wafer Foundry

Customized 6 8 12 inch Crystal Iron Ring Wafer Cutting Film Hoop for Wafer Foundry

The selection material of Stainless Steel Wafer Iron Rings is through SGS certification, high bending strength, high hardness, can bear high load, high wear, corrosive media.

Nitrogen UV Curing Systems Multiple 6 inches Wafer Dicing Machine

Nitrogen UV Curing Systems Multiple 6 inches Wafer Dicing Machine

Curing multiple 6 inches UV Wafer at the same time, UV Film Tape Curing Systems reduce the adhesive strength of all UV-sensitive dicing tapes under controlled environment.

Customized UV LED Cold Light Source UV LED Exposure Unit 365nm 395nm

Customized UV LED Cold Light Source UV LED Exposure Unit 365nm 395nm

Professional Manufacturing UV Wafer Tape Curing Machine is low calorie, good bonding performance, fast speed, environmental protection equipment.

Clamshell 500*500mm UV Tape UV Curing Systems Reducing Blue Film Viscosity

Clamshell 500*500mm UV Tape UV Curing Systems Reducing Blue Film Viscosity

Adhesive strength becomes lower when UV(Ultraviolet light) is irradiated by UV Tape UV Curing Systems.