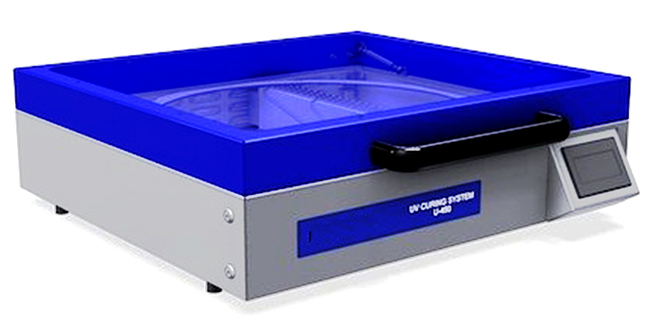

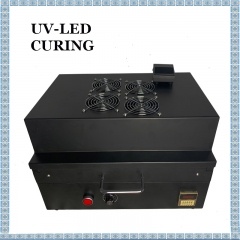

DSXUV LEDUV Curing Systems are built for wafers with frame up to 450mm. The UV LED generates a wavelength of 365nm with an optical power output of maximum 800mW.

model no. :

LED UV Degumming MachineBrand:

DSXUVport of dispatch :

ShenzhenPayment :

T/T 100% before shipmentoriginal region :

ChinaOpening the cover and inserting the wafer to the glass pane, then closing the lid, the UV LED Exposure Machine will start immediately. Curing is completed after about 10-60 seconds, yielding a consistent throughput of 50 to 180 wafers/hour. Fully adjustable exposure dose ranges between 80 mJ / cm2 to 1000 mJ / cm2.

There are numerous UV LED benefits such as less damage to the workpiece by exposure at ambient temperature, a very long lifetime, low power consumption, and safety for replacing the light source because it does not get hot compared to mercury lamps. Equipped with a high-output LED driver, we can achieve an exposure output over 600mW/cm2 (at 6.5mm work distance).

Feature of 6/8/12inch UV Light Curing Machine:

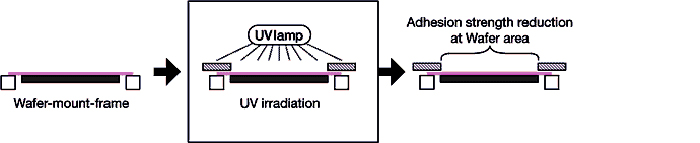

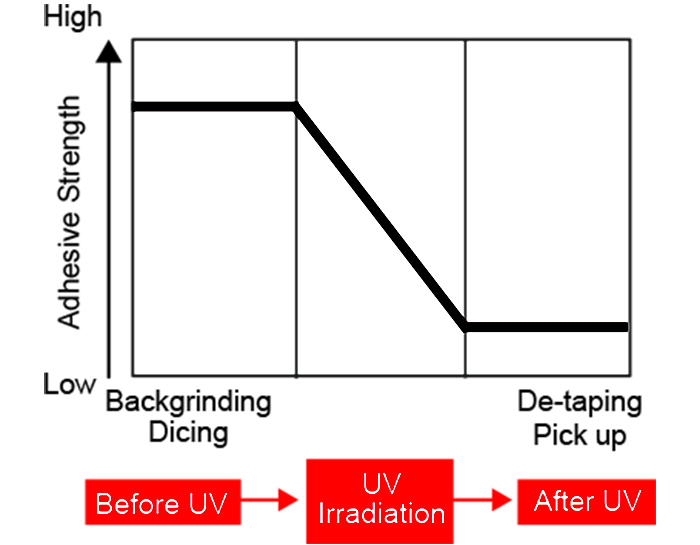

Homogeneous Debonding

Specifications of Silicon Wafer LED UV Curing Equipment :

Frame size: 6/8/12 inches

Types of film: UV film

Wafer: 12 inches and under

Radiation light source: LED UV light source, cold light source, 365nm

Intensity: 600-1000mW/cm2

Place the fixture: 6/8/12 inches wafer can switch with each other

Handling mode: manual put in and take out

Product fixed: alignment pin location

Electric power supply: 220V, 350W,8A

Volume: 645mm*620mm*195mm (L*W*H)

Net weight: 40-50KG

Performance of Dicing UV Flim Degumming Machine:

PLC + touch screen, software control

Irradiation time: 1-999s setting

Production capacity per hour: about 200pcs for general products

Pre-charge nitrogen setting

Key Features of Automatic LED UV Curing Systems :

Low costing procurement = Lowest total cost of ownership (COO)!

No development of harmful ozone

Zero warm-up time

Long service life of UV-LEDs (10,000hrs+)

Low intensity drop (5% in 10,000hours)

No thermal influence on the film

Compact and robust table design

Short installation and implementation time

Low maintenance costs

Conforms to IEC204-1 safety standards

Productivity 50-180 wafer / hr.

6 Inches Dicing Wafer Frame Iron Hoop Semiconductor Fixed Cutting Ring SUS420J Material

6 Inches Dicing Wafer Frame Iron Hoop Semiconductor Fixed Cutting Ring SUS420J Material

6 inches Wafer Expander Rings is used for semiconductor packaging, film, cutting, adhesive process bearing appliances.

12 inches Wafer Frame Dicing Cutting Ring Round Fixed Silicon Disk Iron Ring For Wafer Blue Film

12 inches Wafer Frame Dicing Cutting Ring Round Fixed Silicon Disk Iron Ring For Wafer Blue Film

Stainless Steel 12'' Iron Ring Wafer Frame is strong hardness, resistance to bending, good stickiness, durability.

Customized 6 8 12 inch Crystal Iron Ring Wafer Cutting Film Hoop for Wafer Foundry

Customized 6 8 12 inch Crystal Iron Ring Wafer Cutting Film Hoop for Wafer Foundry

The selection material of Stainless Steel Wafer Iron Rings is through SGS certification, high bending strength, high hardness, can bear high load, high wear, corrosive media.

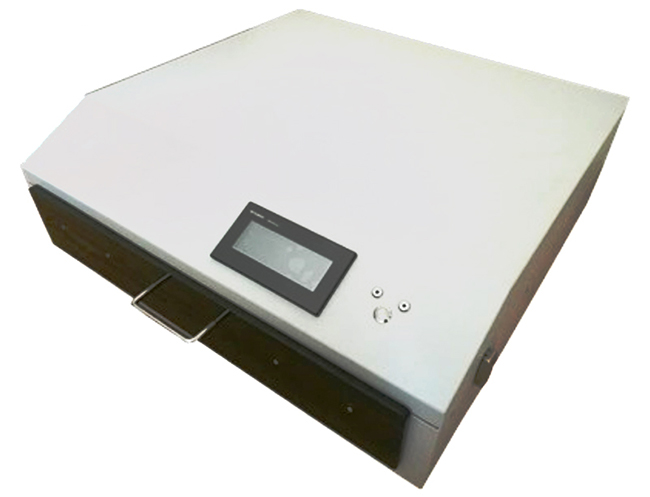

Nitrogen UV Curing Systems Multiple 6 inches Wafer Dicing Machine

Nitrogen UV Curing Systems Multiple 6 inches Wafer Dicing Machine

Curing multiple 6 inches UV Wafer at the same time, UV Film Tape Curing Systems reduce the adhesive strength of all UV-sensitive dicing tapes under controlled environment.

Customized UV LED Cold Light Source UV LED Exposure Unit 365nm 395nm

Customized UV LED Cold Light Source UV LED Exposure Unit 365nm 395nm

Professional Manufacturing UV Wafer Tape Curing Machine is low calorie, good bonding performance, fast speed, environmental protection equipment.

Clamshell 500*500mm UV Tape UV Curing Systems Reducing Blue Film Viscosity

Clamshell 500*500mm UV Tape UV Curing Systems Reducing Blue Film Viscosity

Adhesive strength becomes lower when UV(Ultraviolet light) is irradiated by UV Tape UV Curing Systems.