High Quality UV LED Curing Systems has 365nm 395nm 405nm, water cooling, 600*30mm emitting window size.

model no. :

UV LED Lamp Curing SystemBrand:

DSXUVport of dispatch :

SHENZHENPayment :

T/T 100% Before Shipmentoriginal region :

CHINA

High Quality UV LED Lamp Curing System has 365nm 395nm 405nm, water cooling, 600*30mm emitting window size.

Quick Details of Linear Irradiation UV Exposure Machine for UV Printing :

|

Type |

UV LED |

|

Model Number |

UV-LED CURING-II |

|

Chip Material |

AlGaInP |

|

Emitting Color |

Blue |

|

Luminous Intensity |

Max. 20W/cm^2 |

|

Luminous Flux(lm) |

30-40lm |

|

Optical Attenuation(%) |

10 |

|

Power |

0.1W |

|

Power Dissipation |

2000 |

|

Viewing Angle(°) |

55 |

|

Color Rendering Index(Ra) |

100 |

|

Color Temperature |

Ultraviolet |

|

Operating Temperature(℃) |

-10 - 50 |

|

Storage Temperature(℃) |

-10 - 50 |

|

Place of Origin |

Guangdong, China (Mainland) |

|

Brand Name |

UV-LED CURING |

|

Certification |

CE, RoHS |

|

Application |

Printing |

|

Wavelength |

395nm |

|

Product name |

200w High Power UV LED |

|

Item name |

UV LED Head |

|

Warranty |

1 Years |

|

Main Parts |

Controller |

|

Product Type |

High Power COB UV LED |

|

Cooling Method |

Air Cooled |

|

Wavelength |

395nm / 405nm |

Packaging & Delivery of High Quality 395nm UV Lightsource Systems Curing UV Glue :

Packaging Details : Standard export cartons or processed wooden case according customer's request.

Delivery Time : 25 days after payment

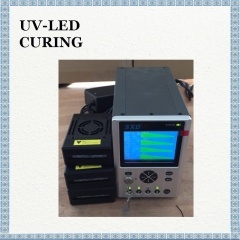

Technical Data of Low Temperature 405nm UV Paint Curing Machine Controller :

|

Type |

XYUV-4II |

|

|

Channel |

One |

|

|

The size of controller |

L304*W284*H90mm |

|

|

Terminal I/O |

Input |

Pedal switch & serial RS-232 communication signals |

|

Output |

serial RS-232 communication signals |

|

|

Cooling method of controller |

Air cooling |

|

|

Power supply voltage |

AC100~240V±10%(50/60HZ) |

|

|

Operation mode |

Touch Panel |

|

|

Ambient temperature and humidity |

Ambient temperature:-10℃—50℃ Relative humidity:25%—85%RH |

|

|

Dimming/Exposure control |

Digital Debugging,Manual exposure control,Foot control or timing control (0.1~9999S) |

|

|

Setting operation |

Using the operating switch is set,Power key parameter switch,RS-232 |

|

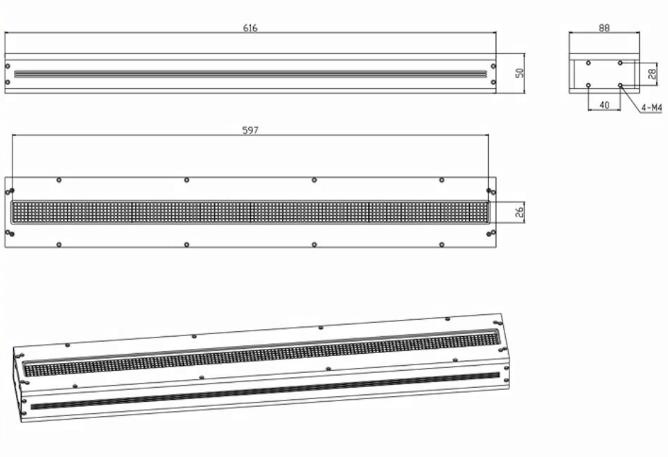

Technical Data of High Performance UV LED Curing Systems for Bonding :

|

product model |

emitting window size |

wavelength |

cooling method |

peak irradiation |

irradiation distance |

|

UV-LED CURING-S792-600x30 |

600X30mm |

395nm |

water cooling |

16000mw/cm² |

10-30mm |

Hand-held UV Curing Equipment for Label Printing UV Curing Machine

Hand-held UV Curing Equipment for Label Printing UV Curing Machine

High Effeciency UV LED Curing Lamp, because of its extra-long life, energy saving, stable output, high uniformity,has been chosen by customers. And also, mulyiple control modes is one of its advantages.

UV-LED CURING High Power Water Cooling Customized 395nm LED UV Curing Lamp

UV-LED CURING High Power Water Cooling Customized 395nm LED UV Curing Lamp

Fan/Water cooling is used to High Power 395nm UV LED Curing Lamp. Because of cold light source, it does not produce harmful ultraviolet radiation without thermal radiation and reduce the heat generated by the curing process.

UV-LED CURING Professional Efficient UV LED Curing Lamp

UV-LED CURING Professional Efficient UV LED Curing Lamp

Professional and Effective UV LED Curing Dryer, the wavelength is 365~405nm, is not suitable for nails.

Strongest UV Intensity Class Air-Cooled Line Type UV LED

Strongest UV Intensity Class Air-Cooled Line Type UV LED

Air-Cooled UV LED Linear Light Souce is through professional designed optical lens module outputting a long and narrow UV LED light band, satisfying banding, printing and other production needs.

UV Glue Fast Curing UV LED Linear Light Source 5*50mm 365nm Curing Ink

UV Glue Fast Curing UV LED Linear Light Source 5*50mm 365nm Curing Ink

UV LED Linear Light Source Machine do not need to replace the ink, is power saving, high efficiency, practical, mercury free, etc..

Customized LED Linear-Type UV Curing System

Customized LED Linear-Type UV Curing System

Customized UV LED Linear Light Source System, its luminescent mode emits a linear light spot, is made of numbers of LED chips.