Air-Cooled UV LED Linear Light Souce is through professional designed optical lens module outputting a long and narrow UV LED light band, satisfying banding, printing and other production needs.

model no. :

Air-Cooled UV LEDBrand:

DSXUVport of dispatch :

SHENZHENPayment :

T/Toriginal region :

CHINAHigh Efficiency UV LED Linear Light Source is a light module of UV LED light source. It’s through professional designed optical lens module outputting a long and narrow UV LED light band, satisfying banding, printing and other production needs. The characteristics of linear light source in the inheritance point of light source are characterized by large solidification area and short curing time. Ultra long life, cold light source, no heat radiation, life free of open and close times, high energy, uniform irradiation and other advantages. Compared with the traditional light source, the UV LED light source does not contain toxic substance, it is more safe and green.

Parameter of Customized 395nm UV LED Light Curing Machine for UV Ink :

|

Brand |

DSX |

|

Cable Length |

2.4m |

|

Cable of Irradiation Head Length |

1500mm |

|

Size of Irradiation Head |

260*30*95mm (L*W*H) |

|

Size of Controller |

180*100*145mm (L*W*H) |

|

Size of Power Supply |

170*70*40mm (L*W*H) |

|

Weight of Irradiation Head |

1.4kg |

|

Weight of Power Supply |

0.55kg |

|

Weight of Controller |

1.5kg |

|

Total Weight |

4kg |

Characteristics of Industrial LED Ultraviolet Linear Light Source for Printing :

LED light source is cold light source, without thermal radiation, the temperature of the irradiated product is almost constant, and the irradiation will not be damaged.

1.It is not required to be lighted up immediately, and it reaches 100% power ultraviolet output immediately. The irradiation intensity can reach 9000mW/ cm2, and the irradiation effect is very outstanding.

2.The machine adopts ultra small body, only 1/8 volume of the original high pressure mercury lamp irradiation machine. Irradiation head is from the back of the fuselage, which the equipment can be easily integrated into automatic production lines and equipment, but also save a lot of work space.

3.Without toxic mercury, no ozone, safer, more environmentally friendly, is the best substitute for traditional light sources.

4.Reduce cost, LED direct irradiation, equipment is simple, do not need to output optic cable, reduce cable loss.

5.Foreign imported leading brand, new UV LED lamp bead, its light source life is considerable, reaching 30,000 hours.

6.Different from traditional way of irradiation, the UV LED Linear Light Source Irradiation Machine can switch ON / OFF and without the waste of irradiation.

7.UV LED, according to customers’ demand, can integrate the light source needed by the customers in optical and drive.

8.Independent control multiple LED light head, can be applied to independent station of multiple need single-ended output, effectively reduce equipment configuration, multiple LED illuminate head can be controlled by computer programming model to control the irradiation, further support bonding requirements of high precision, reduce artificial operation error caused by the time.

9.Fan / air cooling, stable signal irradiation power output, extended service life.

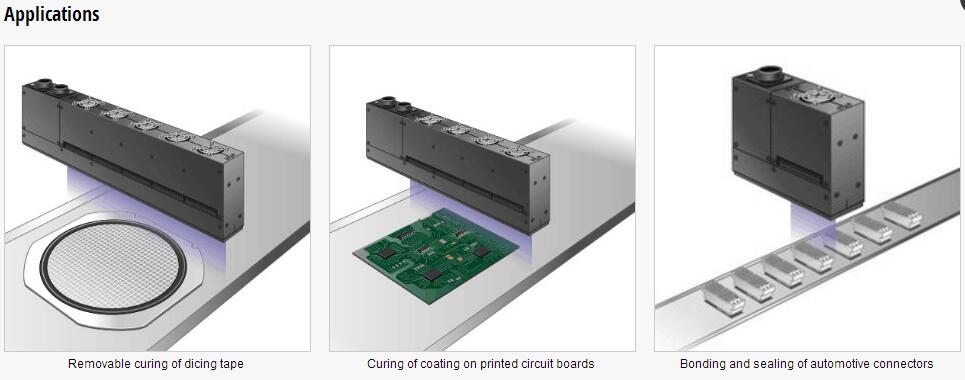

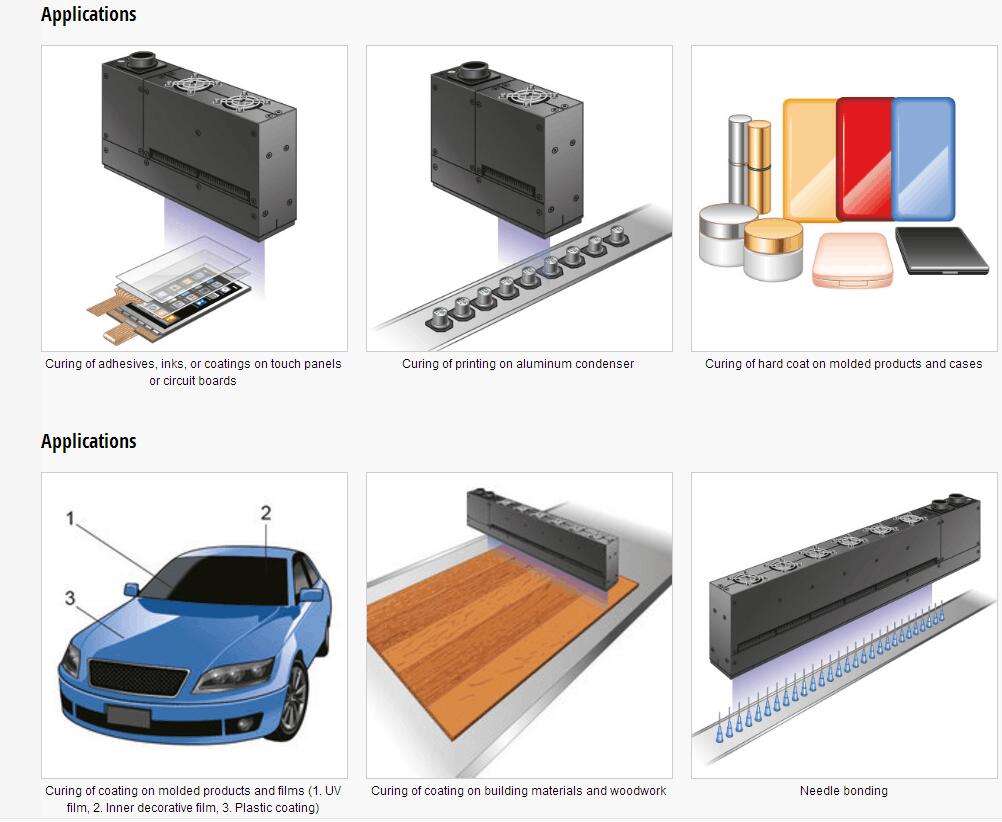

Usage of Small Size LED Ultraviolet Curing Machine for Epoxy Resin :

1.Microelectronics, liquid crystal, PCB, optical communication, optical and other linear light curing.

2.High-grade furniture UV varnish curing.

3.Printing security detection

4.Crafts spray solidified.

5.TFT-LCD panel encapsulation.

6.Capacitance screen side curing, encapsulation curing.

7.Mobile phone screen refurbished adhesive side curing.

8.The screen of LED, LCD, OLED encapsulation curing.

9.Linear curing, gap curing, gap adhesive.

Cautions of Strip Type 365nm LED Ultraviolet Curing Light Source :

1.Please do not see directly UV light and do not irradiation skin. Otherwise, It will damage you eyesight and skin.

2.Please do not bend the cable frequently. Otherwise, it will break line.

3.Please do not dismantling equipment, will lead to electronic circuit and UV Light revealed.

4.Please do not touch irradiation head when the device is out of power or energized.

Hand-held UV Curing Equipment for Label Printing UV Curing Machine

Hand-held UV Curing Equipment for Label Printing UV Curing Machine

High Effeciency UV LED Curing Lamp, because of its extra-long life, energy saving, stable output, high uniformity,has been chosen by customers. And also, mulyiple control modes is one of its advantages.

UV-LED CURING High Power Water Cooling Customized 395nm LED UV Curing Lamp

UV-LED CURING High Power Water Cooling Customized 395nm LED UV Curing Lamp

Fan/Water cooling is used to High Power 395nm UV LED Curing Lamp. Because of cold light source, it does not produce harmful ultraviolet radiation without thermal radiation and reduce the heat generated by the curing process.

UV-LED CURING Professional Efficient UV LED Curing Lamp

UV-LED CURING Professional Efficient UV LED Curing Lamp

Professional and Effective UV LED Curing Dryer, the wavelength is 365~405nm, is not suitable for nails.

UV Glue Fast Curing UV LED Linear Light Source 5*50mm 365nm Curing Ink

UV Glue Fast Curing UV LED Linear Light Source 5*50mm 365nm Curing Ink

UV LED Linear Light Source Machine do not need to replace the ink, is power saving, high efficiency, practical, mercury free, etc..

Customized LED Linear-Type UV Curing System

Customized LED Linear-Type UV Curing System

Customized UV LED Linear Light Source System, its luminescent mode emits a linear light spot, is made of numbers of LED chips.

1000w 395nm System Printing LED Lamp Curing Machine UV Light

1000w 395nm System Printing LED Lamp Curing Machine UV Light

1000w 395nm UV LED Lamp Curing Machine is stable output, high uniformity, cold light source, low temperature.