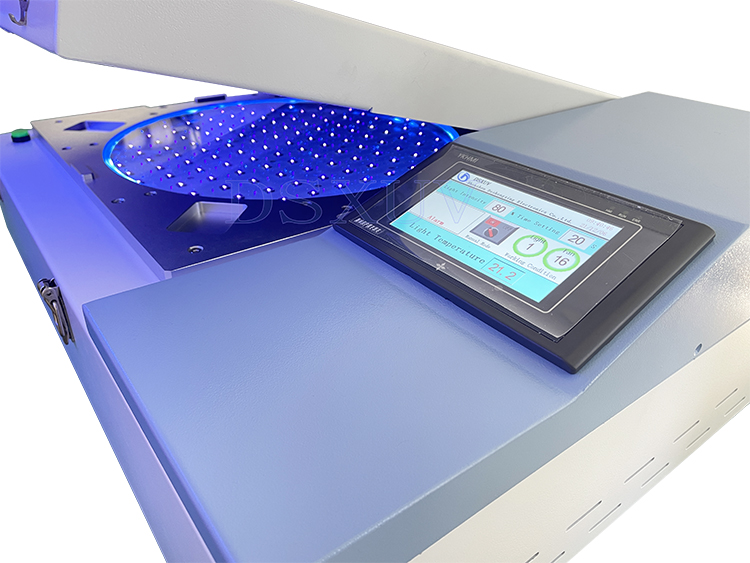

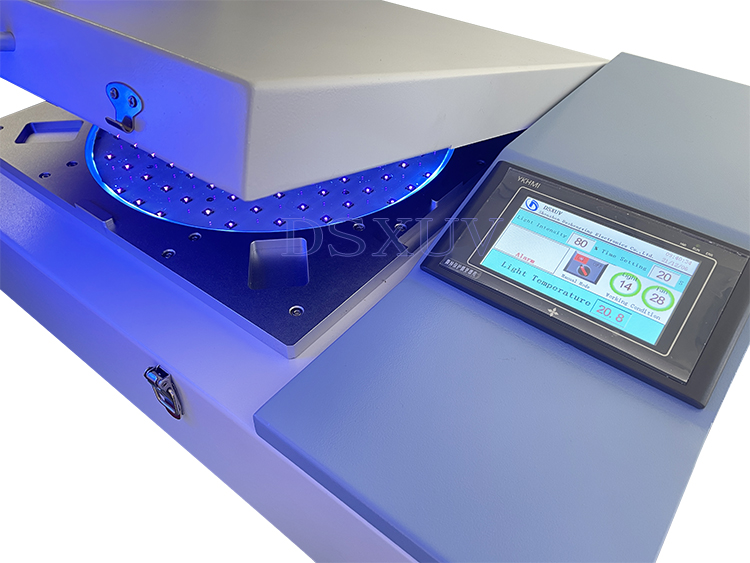

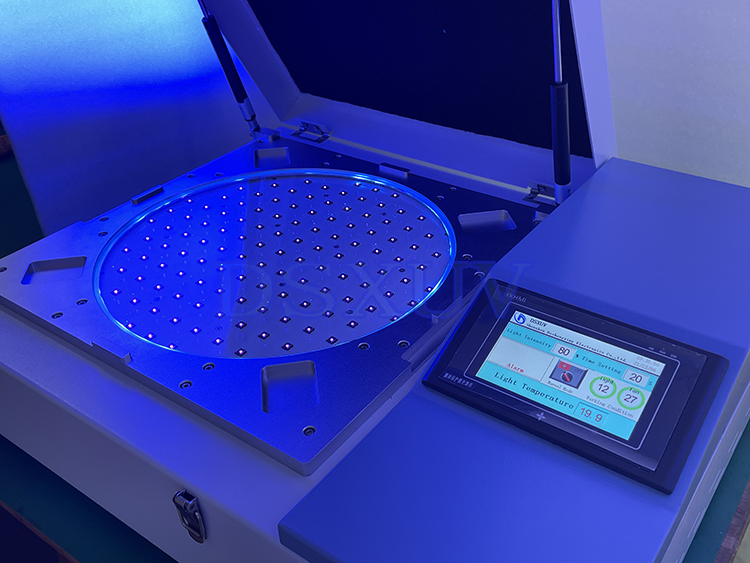

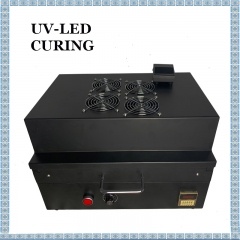

6/8/12 inches UV Tape UV Curing Systems is with high efficiency of degumming ability, can quickly reduce the viscosity of UV film affixed to the materials.

model no. :

UV LED Curing SystemsBrand:

DSXUVport of dispatch :

ShenzhenPayment :

T/T 100% before shipmentoriginal region :

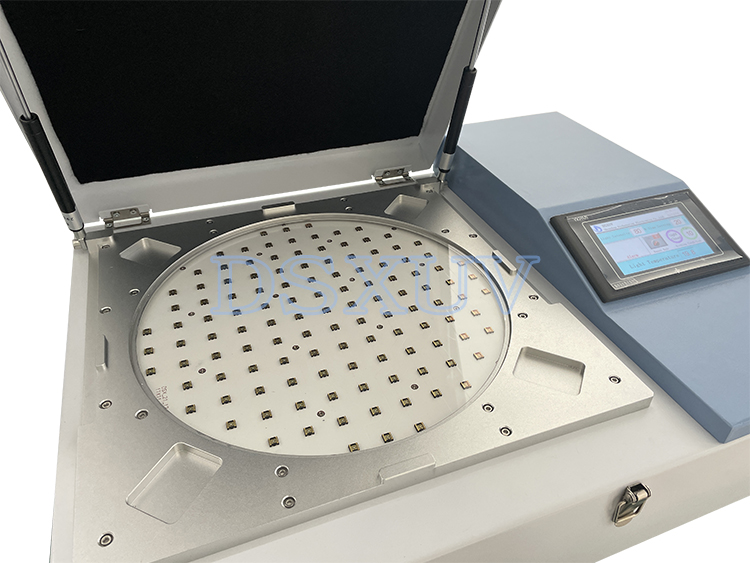

ChinaSuitable for optical lens, LED, IC, semiconductor, integrated circuit board, mobile hard disk and other semiconductor materials, glass filter and other UV film degumming. UV Tape UV Curing Systems is a UV film and cutting film adhesive tape viscosity reduction and removal of the adhesive fully automatic equipment. 6/8/12 inches Wafer Chip UV Film Degumming Machine 365nm is with bracket fixture device, with high efficiency of adhesive ability, can quickly reduce the viscosity of UV film affixed to the materials.

Parameters of Wafer Chip UV Curing Light Source:

Model : DSXUV-Tape-320

Outside dimension : 650*530*201mm

LED : NCSU033C 365nm UV LED

Cooling method : air cooling

Input power : 11-240V AC 50-60Hz

Total power : 370W

Lighting : bottom to the up

Function : can adjust time, intensity (0-100%)

Glass : quartz glass

Warranty : 1 year

Features of UV LED Curing Systems:

1.Small body, suitable for 6/8/10/12 inch wafer chip irradiation

2.Adjustable time and brightness, touch screen operation, simple and convenient

3.Bottom-up irradiation, convenient to place the wafer semiconductor chip

4.LED cold light source, environmental protection products, with low temperature, uniform exposure, compact structure, low energy consumption, is the ideal model of semiconductor industry, and low temperature has no damage to thermal materials

5.The service life is more than 10 times longer than ordinary mercury lamp, continuous service life of 15000-30000h

6.Zero maintenance cost, long term work without replacing the light source parts

7.Closed light source design, no UV side leakage, no damage to human body

8.The degumming speed is fast, it can be degumming in a few seconds

9.Can be compatible with small size

6 Inches Dicing Wafer Frame Iron Hoop Semiconductor Fixed Cutting Ring SUS420J Material

6 Inches Dicing Wafer Frame Iron Hoop Semiconductor Fixed Cutting Ring SUS420J Material

6 inches Wafer Expander Rings is used for semiconductor packaging, film, cutting, adhesive process bearing appliances.

12 inches Wafer Frame Dicing Cutting Ring Round Fixed Silicon Disk Iron Ring For Wafer Blue Film

12 inches Wafer Frame Dicing Cutting Ring Round Fixed Silicon Disk Iron Ring For Wafer Blue Film

Stainless Steel 12'' Iron Ring Wafer Frame is strong hardness, resistance to bending, good stickiness, durability.

Customized 6 8 12 inch Crystal Iron Ring Wafer Cutting Film Hoop for Wafer Foundry

Customized 6 8 12 inch Crystal Iron Ring Wafer Cutting Film Hoop for Wafer Foundry

The selection material of Stainless Steel Wafer Iron Rings is through SGS certification, high bending strength, high hardness, can bear high load, high wear, corrosive media.

Nitrogen UV Curing Systems Multiple 6 inches Wafer Dicing Machine

Nitrogen UV Curing Systems Multiple 6 inches Wafer Dicing Machine

Curing multiple 6 inches UV Wafer at the same time, UV Film Tape Curing Systems reduce the adhesive strength of all UV-sensitive dicing tapes under controlled environment.

Customized UV LED Cold Light Source UV LED Exposure Unit 365nm 395nm

Customized UV LED Cold Light Source UV LED Exposure Unit 365nm 395nm

Professional Manufacturing UV Wafer Tape Curing Machine is low calorie, good bonding performance, fast speed, environmental protection equipment.

Clamshell 500*500mm UV Tape UV Curing Systems Reducing Blue Film Viscosity

Clamshell 500*500mm UV Tape UV Curing Systems Reducing Blue Film Viscosity

Adhesive strength becomes lower when UV(Ultraviolet light) is irradiated by UV Tape UV Curing Systems.