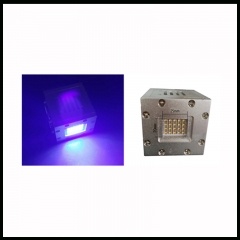

High Efficiency UV LED Curing System has the size of 365nm, 385nm, 395nm, 405nm. The produce can greatly save energy.

model no. :

Energy Saving UV LED Curing Systems for CoatingBrand:

DSXUVport of dispatch :

SHENZHENPayment :

T/Toriginal region :

CHINALead Time :

15-30 DAYSIf you asked what products I recommend to you, Energy Saving UV LED Curing Systems Curing UV Coating is a best choice. Professional LED UV Curing Equipment for UV ink, belongs to Rec Area UV Led Curing, having the size of 365nm, 385nm, 395nm, 405nm. The produce can greatly save energy.

Product Parameters of Powerful LED UV Curing Machine Cure UV Coating :

Type

UV LED

Model Number

UV-LED CURING S264-100x100

Chip Material

GaAs

Emitting Color

Ultraviolet

Luminous Intensity

8W/CM2

Luminous Flux(lm)

30-40lm

Optical Attenuation(%)

0.1

Power

8W/CM2

Power Dissipation

700

Viewing Angle(°)

120

Color Rendering Index(Ra)

0.1

Color Temperature

365 - 405 nm

Operating Temperature(℃)

-10 - 50

Storage Temperature(℃)

-10 - 50

Place of Origin

Guangdong, China (Mainland)

Brand Name

UV-LED CURING

Technical Data of Cool UV Light Source UV Light Curing UV Adhesive Controller:

Type

XYUV - 2

Channel

Two

The size of controller

L400*W360*H110mm

Terminal I/O

Input

Pedal switch & serial RS-232 communication signals

Output

Serial RS-232 communication signals

Cooling method of controller

Air cooling

Power supply voltage

AC100~240V±10%(50/60HZ)

Operation mode

Key Panel

Ambient temperature and humidity

Ambient temperature: -10℃—50℃ Relative humidity: 25%—85%RH

Dimming/Exposure control

Digital Debugging, Manual exposure control, Foot control or timing control (0.1~9999s)

Setting operation

Using the operating switch is set, Power key parameter switch, RS-232

External Control

External input

Enter irradiation alone Irradiation stop input, Interlocking, All lights illuminated input, Query switch

External output

REDAY signal, Error signal, Warning Output, Busy output (Various skinhead), +5VOutput(indicator used)

Irradiation Head Specification of Energy Saving 395nm UV Curing Lamps for Label Printing :

Model

UV-LED CURING S264-200X30-395

Setting Specification

700mA Constant Current

Electronic Power

800W

Electric Power

Water Cooling

Control

UV-4ⅡController, Channel Alone Control

Curing Area

Length 20mm; Width:600mm

Irradiation Distance

10-15mm

UV LED Curing Head

Wavelength

395nm

Peak Irradiance

11W/cm2

Uniformity

±5~8%

Grade

No.1,3B Product

Air Cooling UV Solidify Machine Curing Mobile Phone Touch Screen

Air Cooling UV Solidify Machine Curing Mobile Phone Touch Screen

Air Cooling UV Solidify Machine, Emitting Window:104*25mm, is designed as a simple, low cost, small form factor air-cooled UV LED curing lamp for pinning and curing of inks, coatings and adhesives, mobile phone touch screen.

104*25mm Water Cooling UV LED Curing System

104*25mm Water Cooling UV LED Curing System

The WnnexCureTM EB168 UV Light Emitting Diode provides highest output power in an extremely medium mechanical package for high speed pinning and full cure applications. The EB168 UV LED Light Source is CE, RoHS, and REACH compliant.

Top Quality 365nm UV LED Curing Equipment Drying UV Glue

Top Quality 365nm UV LED Curing Equipment Drying UV Glue

100*100mm high power top quality power saving 365nm LED UV Curing Machine Curing UV Glue can be customized. You know 365nm is the best wavelength to cure UV glue.

365nm LED UV Curing UV Glue UV Curing Machine for Bonding

365nm LED UV Curing UV Glue UV Curing Machine for Bonding

Customized 365nm UV LED Curing System for lens bonding. UV LED Area Curing System can make glue curing, wavelength 365nm, rec area : 20*25mm, quickly, effective to cure.

Bar Type LED UV Curing System for UV Ink Use to Cure

Bar Type LED UV Curing System for UV Ink Use to Cure

Energy Saving Bar Type LED UV Curing System, This kind of UV LED curing system can be used for curing UV ink, UV varnish and UV paint and is suitable for flex printer, offset printer, flatbed printer and flexo printer.

High Power UV LED Dryer for UV Adhesive Curing System 30*120mm

High Power UV LED Dryer for UV Adhesive Curing System 30*120mm

High Power UV LED Dryer for UV Adhesive Curing System is 30*120mm, 365nm.