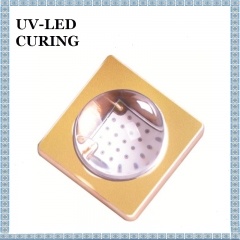

255nm Ultraviolet LED Light Beads is widely used in UV light curing system, medical treatment, sterilization and disinfectionand other fields.

model no. :

255nm UVC UV LEDBrand:

DSXUVport of dispatch :

ShenzhenPayment :

T/T 100% Before Shipmentoriginal region :

China255nm Disinfectant UVC Ultraviolet Light Chips is used in water/air/surface sterilization, used for disinfection cabinet, microwave oven and other household appliances.

Features:

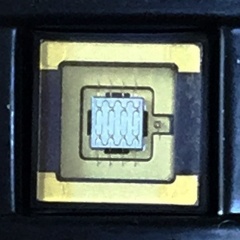

1. Package size: 3.85*3.85*1.4mm

2. Ceramic substrate package is adopted

3. Welding method: reflow welding

4. Comply with RoHS standards

5. Adopt high reliability package with stable energy

6. Eutectic process is adopted

Application Scope:

1.Water/air/surface sterilization, used for disinfection cabinet, microwave oven and other household appliances

2.Clean water sterilization, food and object surface sterilization, etc

3.Widely used in UV light curing system, medical treatment, sterilization and disinfection, plant purification equipment, gemstone identification, banknote identification, light resin hardening and other fields.

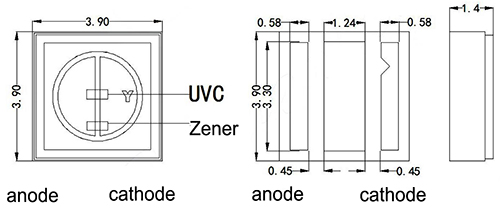

Outside Dimension :

Remark:

1. All dimensions are in mm

2. The plus or minus tolerance is 0.1mm without clear marking

Parameters : (Ta=25℃)

|

Process |

Symbol |

Test Condition (mA) |

Minimum Value |

Typical Value |

Maximum Value |

Unit |

|

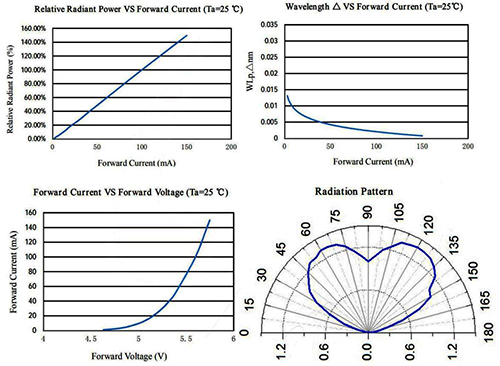

Forward voltage |

VF |

IF=100mA |

4.5 |

6.0 |

7.5 |

V |

|

Forward current |

IF |

- |

- |

100 |

120 |

mA |

|

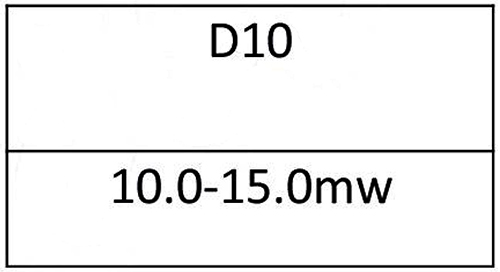

Optical power |

IV |

- |

10 |

11 |

15 |

mW |

|

Irradiation Angle |

2θ 1/2 |

IF=100mA |

- |

130 |

- |

° |

|

Wavelength |

λP |

IF=100mA |

250 |

255 |

260 |

nm |

|

Half wave width |

△λ |

IF=100mA |

- |

11 |

- |

nm |

|

Thermal resistance |

R |

IF=100mA |

- |

25 |

- |

℃/W |

Note:

1. The measured tolerance of the output optical power is 10%

2. Voltage measurement tolerance is 0.1V

3. The measurement tolerance of the main wavelength is 1nm

4. Both can be operated with pulse (frequency: 100Hz, duty ratio: 5%), and the maximum working current is 260mA

Output Power Grade

Note:

In order to obtain a better stable output, UV-LED needs a good heat dissipation environment or heat dissipation system. It is recommended that the lamp bead should not exceed 50℃ in working condition.

Typical Photoelectric Parameter Curve

Reliability Test Project and Conditions :

|

Test Item |

Test Conditions |

Test Current |

Test Time |

Quantity of Test |

Passing Rate |

|

Hot and cold impact |

Ta*: -40℃~50℃, 1min (10sec) 1min |

N/A |

50 cycles |

25 |

100% |

|

Temperature cycle |

Ta*: -40℃~25℃~85℃~25℃, 30min 5min 30min 5min |

N/A |

20 cycles |

25 |

100% |

|

Moisture resistance |

Ta*: 25℃~85℃~-10℃, RH=90%,24 hrs/1 cycle |

N/A |

10 cycles |

25 |

100% |

|

High temperature storage |

Ta=120℃ |

N/A |

1000 hrs |

25 |

100% |

|

High temperature high humidity storage |

Ta=85℃, RH=90% |

N/A |

200 hrs |

25 |

100% |

|

Low temperature storage |

Ta=-40℃ |

N/A |

1000 hrs |

25 |

100% |

|

Vibratory test |

100-2000-100Hz Sweep 4min 200m/s2,3, 4 periods |

N/A |

48 min |

25 |

100% |

|

Solder-ability test |

245℃, 5sec (aged in steam for 16 hours) |

N/A |

|

25 |

100% |

|

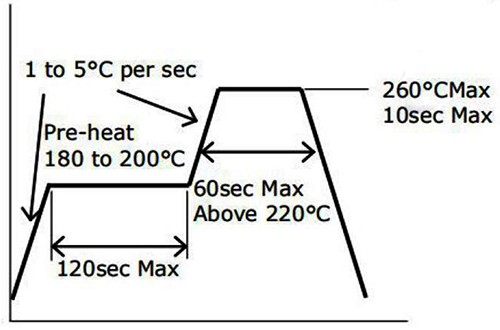

Heat resistance test for reflow welding |

260℃, 10sec |

N/A |

|

25 |

100% |

|

Antistatic Ability |

R=1.5kΩ, C=100pF, V=±2KV, three times |

N/A |

|

25 |

100% |

Criterion for unqualified reliability test :

IV : attenuation is excess of 30%

IF : change over 20%

Remark :

The test of the same sample experimental result should be completed within 2 hours

The test shall be carried out only after each test is completed and the material returns to normal environmental conditions.

Notes :

1.Storage

In order to avoid the influence of moisture, we recommend that the product be stored at 5-30 ℃ before opening the package, and the relative humidity is less than 60%.

The LED light source that has been opened should be used and installed within 24 hours. If it is not used up, it should be dehumidified and sealed after vacuuming. Dehumidified must be carried out when the humidity card is opened for more than a week. Dehumidification conditions : 60℃±5℃, 12H

The product shall be sealed and kept for one year.

2.Matters needing attention in assembly

Welding conditions : the product must be operated by reflow welding. The maximum temperature of the reflow curve shall not exceed 260℃. during operation on storage, external force or sharp objects of more than 1000g shall not act on the surface of LED lamp beads (such as external force, like pressure, friction and tools such as pliers and tweezers), so as to avoid component damage.

If these conditions are exceeded, we will not guarantee the stability of the product. If these conditions are exceeded, please be sure to conduct a risk assessment.

3.Anti-static measures

Take adequate precautions to prevent static electricity, such as with a static ring or anti-static finger sleeve. Each manufacturing plant with respect to the product (plant, equipment, machine, carrier and transport unit) shall be connected to the ground to avoid electrification of the product.

4.Temperature control

In order to reduce the contract thermal resistance during the assembly, please note that during the assembly process, the heat dissipation fins shall adopt good quality thermal conductive paste and have a reasonable distribution area, without too little or high or low inequality.

The heat dissipation medium shall pass the voltage withstand test of dielectric at least 500V.

5.Drive control

This product needs to be driven by constant current source, and the output current conforms to the power use range in the specification book. If constant voltage source or other use conditions are needed, please conduct risk assessment of the use effect.

6.Others :

This product may bot be used under any of the following conditions. If the product is used under any of the following conditions, please evaluate its use risk and effect.

-- directly or indirectly getting wet, as in the rain

-- damaged or eroded by sea water

-- exposure to corrosive gases (e.g. CI2, H2S, NH3, SOx, NOx, etc.)

-- exposure to dust, liquid, or oil

All high power light emitting LED products are mounted on aluminum metal core printed circuit boards that can be lit directly. But we do not recommend lighting high-power LED lighting for more than 5 seconds without a proper cooling equipment room.

The product emits a short wavelength LED. During use, LEDs emit high levels of ultraviolet light, which can damage the skin and eyes.

UV light can damage the skin and even has the risk of cancer. Avoid exposure to UV light during operation.

Take care to avoid direct exposure to ultraviolet light without UV protective glasses. LEDs are not allowed to look directly at their lenses when lit.

Reflow soldering should not be done more than twice. The maximum temperature for reflow soldering is recommended below 260℃. when the temperature exceeds 260℃, it is very likely to cause LED product failure.

In order to obtain a better stable output, UV LED needs a goods heat dissipation environment or heat dissipation system. It is recommended that the lamp bead should not exceed 50℃ in working condition.

Lead-free reflow welding curves are as follows (the maximum temperature is set at 260℃)

High Power 365nm UV LED Light Beads UV LED Chip

High Power 365nm UV LED Light Beads UV LED Chip

High Power 365nm UV LED Light Beads is used for UV curing, fluorescent spectroscopy, sensors and monitors, phototherapy, printing, coating, etc..

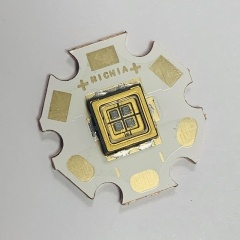

NICHIA NC4U133A NC4U133B 12W 365nm Ultraviolet Bead Four Chip Series Packaging

NICHIA NC4U133A NC4U133B 12W 365nm Ultraviolet Bead Four Chip Series Packaging

High Power 12W NICHIA UV Light Beads curing UV ink, UV glue, etc.

LG 70mW 278nm UVC LED UV Disinfection Lamp

LG 70mW 278nm UVC LED UV Disinfection Lamp

High power 70mW UVC LED UV Disinfection Lamp for water treatment air purification, for laboratory test.

NICHIA NWSU333B 365nm UV LED Lamp Beads Curing Light Source

NICHIA NWSU333B 365nm UV LED Lamp Beads Curing Light Source

NWSU333B LED UV Lamp Source is widely used in UV LED Curing Machine, because of its stable output, high uniformity, and save 80% electrical energy than mercury lamp and low energy consumption.

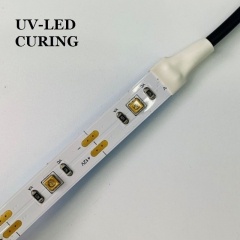

Flexible 270nm UVC LED Sterilization Lamp for Disinfection

Flexible 270nm UVC LED Sterilization Lamp for Disinfection

Deep Ultraviolet UVA+UVC lamp belt application field : pet environment, medical equipment, house disinfection, pharmaceutical manufacturing, laboratory

High Power 4in1 UV LED LG 5w 365nm Ultraviolet Light Bead

High Power 4in1 UV LED LG 5w 365nm Ultraviolet Light Bead

365nm 6868 4in1 LED UV Ink Curing Light Chips is used in UV curing, UV ink curing, photo-catalyst, sensor light, etc.