275nm 60mW UVC LED Light Chip is used for air, surface and water disinfection and purification.

model no. :

UVC LED Chip 280nm DiodeBrand:

DSXUVport of dispatch :

ShenzhenPayment :

T/T 100% Before Shipmentoriginal region :

China

275nm UVC Ultraviolet LED Lamp Beads is widely used in clean water sterilization, food and object surface sterilziation, etc., and can be installed in disinfection cabinet, microwave oven and other household appliances.

Features:

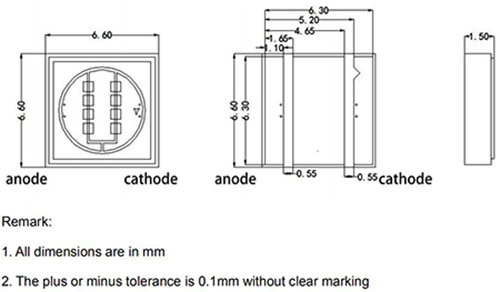

1. Package size: 6.5*6.5*1.5mm

2. Ceramic substrate package is adopted

3. Welding method: reflow welding

4. Comply with RoHS standards

5. Adopt high reliability package with stable energy

6. Eutectic process is adopted

Outside Dimension :

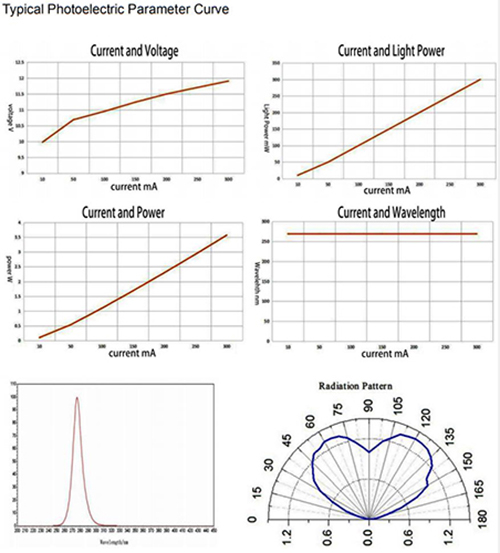

Parameters : (Ta=25℃)

|

Process |

Symbol |

Test Condition (mA) |

Minimum Value |

Typical Value |

Maximum Value |

Unit |

|

Forward voltage |

VF |

IF=180mA |

10 |

12 |

15 |

V |

|

Forward current |

IF |

- |

- |

180 |

260 |

mA |

|

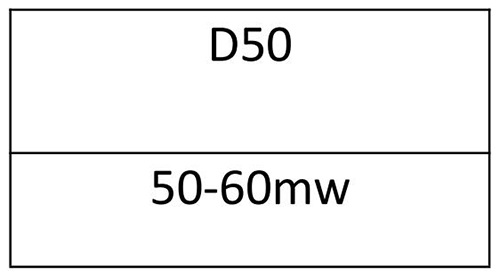

Optical power |

IV |

- |

- |

50 |

70 |

mW |

|

Irradiation Angle |

2θ 1/2 |

IF=180mA |

- |

130 |

- |

° |

|

Wavelength |

λP |

IF=180mA |

270 |

275 |

285 |

nm |

|

Half wave width |

△λ |

IF=180mA |

- |

9.6 |

- |

nm |

|

Thermal resistance |

R |

IF=180mA |

- |

25 |

- |

℃/W |

Note:

1. The measured tolerance of the output optical power is 10%

2. Voltage measurement tolerance is 0.1V

3. The measurement tolerance of the main wavelength is 1nm

4. Both can be operated with pulse (frequency: 100Hz, duty ratio: 5%), and the maximum working current is 260mA

Output Power Grade

Note:

In order to obtain a better stable output, UV-LED needs a good heat dissipation environment or heat dissipation system. It is recommended that the lamp bead should not exceed 50℃ in working condition.

Reliability Test Project and Conditions :

|

Test Item |

Test Conditions |

Test Current |

Test Time |

Quantity of Test |

Passing Rate |

|

Hot and cold impact |

Ta*: -40℃~85℃, 1min (10sec) 1min |

N/A |

50 cycles |

25 |

100% |

|

Temperature cycle |

Ta*: -40℃~25℃~85℃~25℃, 30min 5min 30min 5min |

N/A |

20 cycles |

25 |

100% |

|

Moisture resistance |

Ta*: 25℃~85℃~-10℃, RH=90%,24 hrs/1 cycle |

N/A |

10 cycles |

25 |

100% |

|

High temperature storage |

Ta=120℃ |

N/A |

1000 hrs |

25 |

100% |

|

High temperature high humidity storage |

Ta=85℃, RH=90% |

N/A |

200 hrs |

25 |

100% |

|

Low temperature storage |

Ta=-40℃ |

N/A |

1000 hrs |

25 |

100% |

|

Vibratory test |

100-2000-100Hz Sweep 4min 200m/s2,3, 4 periods |

N/A |

48 min |

25 |

100% |

|

Solder-ability test |

245℃, 5sec (aged in steam for 16 hours) |

N/A |

|

25 |

100% |

|

Heat resistance test for reflow welding |

260℃, 10sec |

N/A |

|

25 |

100% |

|

Antistatic Ability |

R=1.5kΩ, C=100pF, V=±2KV, three times |

N/A |

|

25 |

100% |

Criterion for unqualified reliability test :

IV : attenuation is excess of 30%

IF : change over 20%

Remark :

The test of the same sample experimental result should be completed within 2 hours

The test shall be carried out only after each test is completed and the material returns to normal environmental conditions.

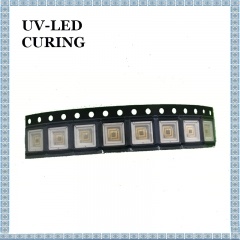

High Power 365nm UV LED Light Beads UV LED Chip

High Power 365nm UV LED Light Beads UV LED Chip

High Power 365nm UV LED Light Beads is used for UV curing, fluorescent spectroscopy, sensors and monitors, phototherapy, printing, coating, etc..

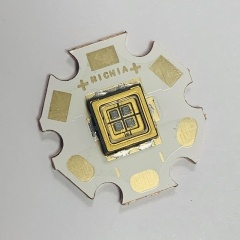

NICHIA NC4U133A NC4U133B 12W 365nm Ultraviolet Bead Four Chip Series Packaging

NICHIA NC4U133A NC4U133B 12W 365nm Ultraviolet Bead Four Chip Series Packaging

High Power 12W NICHIA UV Light Beads curing UV ink, UV glue, etc.

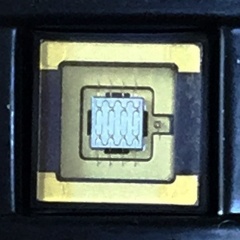

LG 70mW 278nm UVC LED UV Disinfection Lamp

LG 70mW 278nm UVC LED UV Disinfection Lamp

High power 70mW UVC LED UV Disinfection Lamp for water treatment air purification, for laboratory test.

NICHIA NWSU333B 365nm UV LED Lamp Beads Curing Light Source

NICHIA NWSU333B 365nm UV LED Lamp Beads Curing Light Source

NWSU333B LED UV Lamp Source is widely used in UV LED Curing Machine, because of its stable output, high uniformity, and save 80% electrical energy than mercury lamp and low energy consumption.

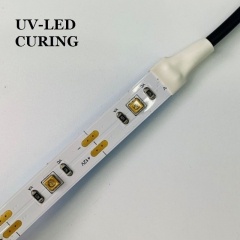

Flexible 270nm UVC LED Sterilization Lamp for Disinfection

Flexible 270nm UVC LED Sterilization Lamp for Disinfection

Deep Ultraviolet UVA+UVC lamp belt application field : pet environment, medical equipment, house disinfection, pharmaceutical manufacturing, laboratory

High Power 4in1 UV LED LG 5w 365nm Ultraviolet Light Bead

High Power 4in1 UV LED LG 5w 365nm Ultraviolet Light Bead

365nm 6868 4in1 LED UV Ink Curing Light Chips is used in UV curing, UV ink curing, photo-catalyst, sensor light, etc.