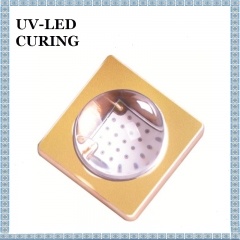

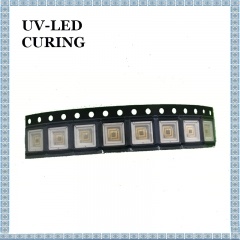

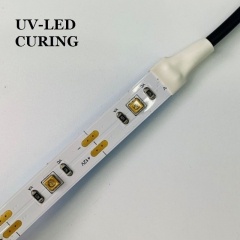

The application of Quartz Lens View Angle deg 30° UV LED for Printing Curing Wavelenth 365-415nm is for UV Curing.

model no. :

Quartz Encapsulates UVLED LampBrand:

DSXUVport of dispatch :

SHENZHENPayment :

T/Toriginal region :

CHINALead Time :

The Same DayQuartz Lens View Angle deg 30° UV LED for Printing Curing Wavelenth 365-415nm is made of high-end packaging material Quartz High End Material Package, aluminium nitride substrate, Taiwan Liansheng 46MIL jumbo size chip, and 99.99% pure gold line.

Features:

1. Emitted Color: White.

2. Lens Appearance: Clean quartz lens

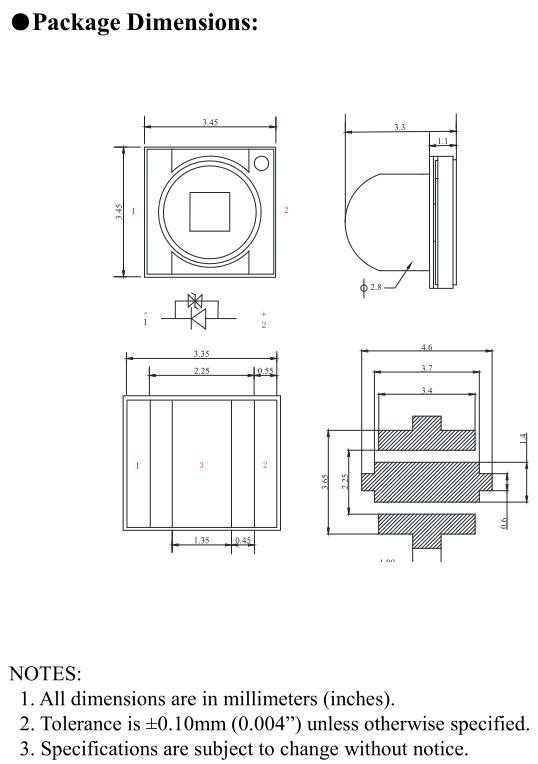

3. 3.45x3.45x3.30mm standard package.

4. Suitable for all SMT assembly methods.

5. Compatible with infrared and vapor phase reflow solder process.

6. Compatible with automatic placement equipment.

7. This product doesn’t contain restriction Substance, comply ROHS standard.

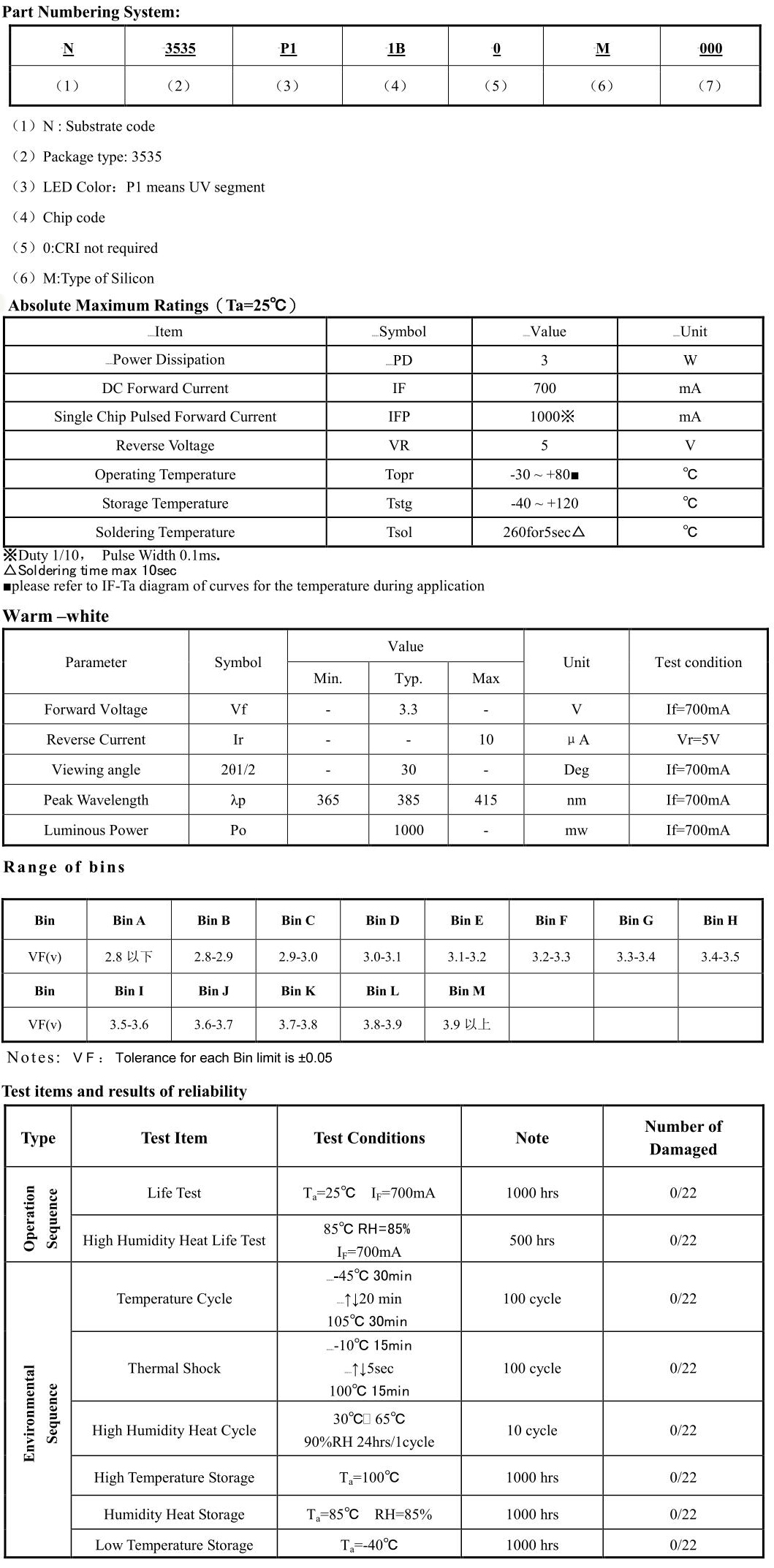

Judgment Criteria ofFfailure for the Reliability

Note:

1. U means the upper limit of specified characteristics. S means initial value.

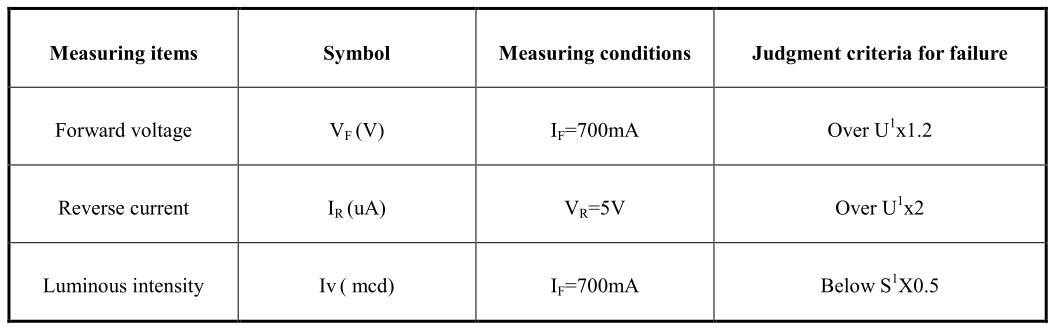

Lens handling

Lens cleaning

In the case where a minimal level of dirt and dust particles can not be guaranteed, a suitable cleaning solution can be applied to the lens surface

1. Try a gentle swabbing using a lint-free swab

2. If needed, the use of lint-free swab and isopropyl alcohol used gently removes dirt from the lens surface

3. Do not use other solvents as they may directly react with the LED assembly

4. Do not use ultrasonic cleaning that the LED will be damaged

Carrier Tape Handling

The following items are recommended when handling the Carrier tape of LEDs

1. Do not twist the carrier tape

2. The inward bending diameter should not smaller than 6cm for carrier tape.

3. Do not bend the tape outward.

4. Storage temperature should not exceed 60℃

Handling :

Care must be taken not to damage LED’s silicon while exposing to high temperature or contact LED’s epoxy resin with hard or sharp objects, such as metal hook, tweezer or sand blasting.

Notes for designing:

Current limiting resistor must be used in the circuit to drive LEDs within the rated figures and not to overload LEDs with instantaneous voltage at the turning ON and OFF cycles.

When using pulse driving, the average current must be within the rated figures. And the circuit should be designed to avoid reverse voltage when turning off the LEDs.

Storage:

In order to avoid the absorption of moisture, it is recommended to solder LEDs as soon as possible after unpacking the sealed envelope.

If the envelope is still packed, to store it in the environment as following:

(1) Temperature : 5℃-30℃(41℉)Humidity : RH 60﹪Max.

(2) After this bag is opened, devices that will be applied to infrared reflow, vapor-phase reflow, or equivalent soldering process must be:

a. Completed within 168 hours.

b. Stored at less than 30% RH.

(3) Devices require baking before mounting, if: (2) a or (2) b is not met.

(4) If baking is required, devices must be baked under below conditions: 48 hours at 60℃±3℃.

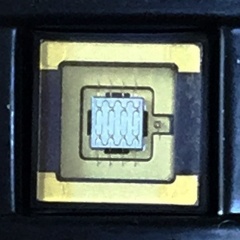

High Power 365nm UV LED Light Beads UV LED Chip

High Power 365nm UV LED Light Beads UV LED Chip

High Power 365nm UV LED Light Beads is used for UV curing, fluorescent spectroscopy, sensors and monitors, phototherapy, printing, coating, etc..

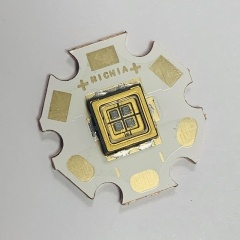

NICHIA NC4U133A NC4U133B 12W 365nm Ultraviolet Bead Four Chip Series Packaging

NICHIA NC4U133A NC4U133B 12W 365nm Ultraviolet Bead Four Chip Series Packaging

High Power 12W NICHIA UV Light Beads curing UV ink, UV glue, etc.

LG 70mW 278nm UVC LED UV Disinfection Lamp

LG 70mW 278nm UVC LED UV Disinfection Lamp

High power 70mW UVC LED UV Disinfection Lamp for water treatment air purification, for laboratory test.

NICHIA NWSU333B 365nm UV LED Lamp Beads Curing Light Source

NICHIA NWSU333B 365nm UV LED Lamp Beads Curing Light Source

NWSU333B LED UV Lamp Source is widely used in UV LED Curing Machine, because of its stable output, high uniformity, and save 80% electrical energy than mercury lamp and low energy consumption.

Flexible 270nm UVC LED Sterilization Lamp for Disinfection

Flexible 270nm UVC LED Sterilization Lamp for Disinfection

Deep Ultraviolet UVA+UVC lamp belt application field : pet environment, medical equipment, house disinfection, pharmaceutical manufacturing, laboratory

High Power 4in1 UV LED LG 5w 365nm Ultraviolet Light Bead

High Power 4in1 UV LED LG 5w 365nm Ultraviolet Light Bead

365nm 6868 4in1 LED UV Ink Curing Light Chips is used in UV curing, UV ink curing, photo-catalyst, sensor light, etc.