2023-07-06 17:21:42

Generally, 2 to 3 UV lamps are installed in the middle part of the paper receiving chain rail, and an exhaust pipe is installed at the top of the paper receiving part, and a UV curing device can also be separately connected, and the conveyor belt is connected to the paper receiving table part. Obviously, the latter, due to the limitation of the conveyor belt speed of the UV curing device, will affect the printing speed, and it is not suitable from the point of view of the footprint. When using the first method, the UV lamp can be set between the unit and the unit, and each unit can be exchanged and used to achieve a wet press dry printing state according to the different requirements of the printed product.

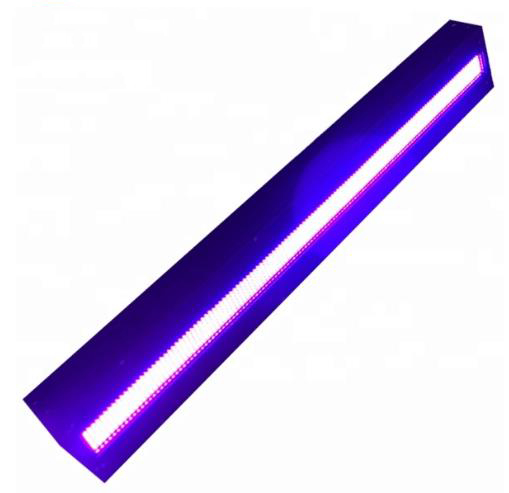

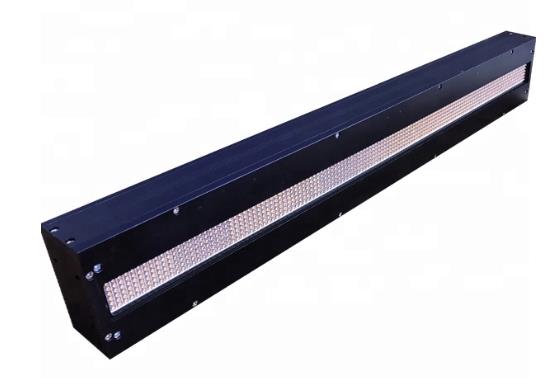

The UV Curing Systems can be equipped with a stepless and adjustable power output, which controls the output power and the printing press in the off-pressure state, and then the output power of the UV lamp is automatically reduced, which can extend the service life of the lamp. UV Curing Units are usually air-cooled and water-cooled at the same time, and each UV lamp is equipped with a mirror to ensure that excess heat is effectively removed during the printing process. At present, the service life of the general UV lamp is 1000 ~ 1500 hours, and if it is used well, it can reach 1500 ~ 2000 hours. At present, the domestic is still mainly imported, of which the products of Germany elthch company and Japan GSM company are more typical.

UV ink to use a special ink roller. The special ink roller's acid resistance, alkali resistance, oil resistance, swelling resistance are better than ordinary ink roller, its high quality performance is specially suitable for UV ink. Usually, the service life of the special ink roller is less than 2 years, and the roller is less than 1 year.

In addition, it is best to install the water cooling device of the ink roller, which can effectively control the temperature of the ink roller and ensure that the quality of the print is not caused by the temperature change after the friction of the UV ink in continuous rapid printing.

The embossing cylinder uses a double diameter cylinder (two turns of the plate cylinder is equivalent to one turn of the embossing cylinder) to ensure the smooth and smooth transfer of the plastic film. The printing sheet is passed to the next cylinder after the stamping cylinder is completed. When the printing machine is running at high speed, it is not easy to fail, and the pressure and impulse force under the printing sheet are kept to a minimum.

The skeleton paper roller replaces the traditional paper roller. A blowing type, a row of air is installed on the paper transfer drum, in the transfer process, the tail of the printed sheet is blown down, and the air cushion will be lifted to prevent dirt or scratches. The other is to use a sliding rod instead of blowing, the two sliding rods are placed on both sides of the printing sheet to avoid contact with the middle of the printing graphic part, the sliding rod can move freely, can be adjusted according to different printing formats.

The skeleton paper roller replaces the traditional paper roller. A blowing type, a row of air is installed on the paper transfer drum, in the transfer process, the tail of the printed sheet is blown down, and the air cushion will be lifted to prevent dirt or scratches. The other is to use a sliding rod instead of blowing, the two sliding rods are placed on both sides of the printing sheet to avoid contact with the middle of the printing graphic part, the sliding rod can move freely, can be adjusted according to different printing formats.

Special steel treatment (such as chrome plating) should be applied to the tips of all paper teeth, paper delivery teeth, and paper receiving teeth to ensure their wear resistance, ensure the accuracy of paper delivery, and prevent overprinting failures caused by slippage. Since the paper receiving teeth need to be cycled from the UV lamp, its own metal structure must be resistant to high temperature, otherwise once deformed, it will seriously affect the printing handover.

The main motor of the printer is an AC motor. Because of the large viscosity and poor fluidity of UV ink, the friction between UV ink rollers is large, and the printing press load is large. Therefore, it is necessary to choose a motor with a higher power than the main motor of an ordinary offset press of the same specification to ensure normal printing.

Due to the high static electricity and dust of sheets such as PVC, it is recommended to install electrostatic devices in the paper feeding and receiving parts. If conditions permit, you can also install dust removal devices in the paper feeding parts.

Business card printing UV offset printing machine to meet the conditions of the printing thickness of 0.1-0.85mm, color accuracy error ≤0.02mm, other functions can be adjusted according to different brands of printing machines.