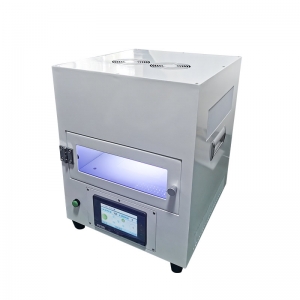

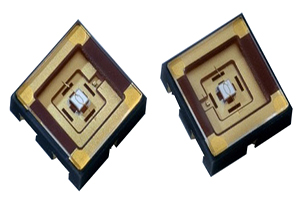

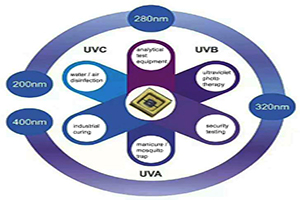

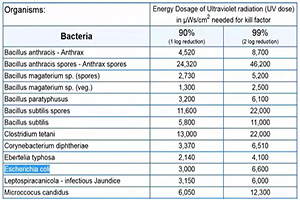

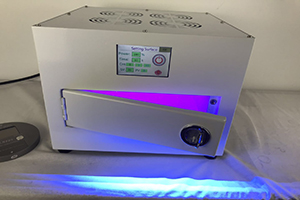

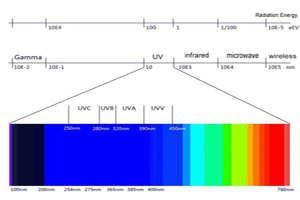

High Power UV LED light curing equipment for UV Curing has widely range of applications and powerful functions, such as medical industry, electronics industry, machinery industry, optical industry, university laboratory, etc.. UV LED light source is safe and reliable, small in size, high photo-electric conversion efficiency, spectral coverage, simple operation and low price. Can UV LED replace the...

continue reading

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español Nederlands

Nederlands العربية

العربية български

български svenska

svenska

+8618924372460

+8618924372460 live:1651063690jennifer

live:1651063690jennifer uvcure@uvspacelight.com

uvcure@uvspacelight.com 0086-18924372460

0086-18924372460