2021-04-23 18:25:27

In the field of electronic optics, the use of UV glue for the gluing of optical lenses has been very common. When curing UV glue, many manufacturers will choose to use UV LED curing machine instead of traditional UV mercury lamp for curing, why? One of the key factors is that the ultraviolet light source produced by the UV LED Curing Systems is a single band, and belongs to the “cold light source”, no thermal radiation damage and other advantages. In contrast to the traditional UV mercury lamp, the use of UV LED Ultraviolet Light can effectively prevent the deformation of the lens when it fits.

The UV LED curing equipment has been mature used in all kinds of gluing requirements of UV glue for optical lenses. For the problem of poor curing effect caused by glue leakage at the edge of the lens, the UV LED curing function developed and produced by Deshengxing Technology effectively solves the problem of bubbles generated in the gluing process of optical lenses or the problem that the lens edge solidifies and does not dry.

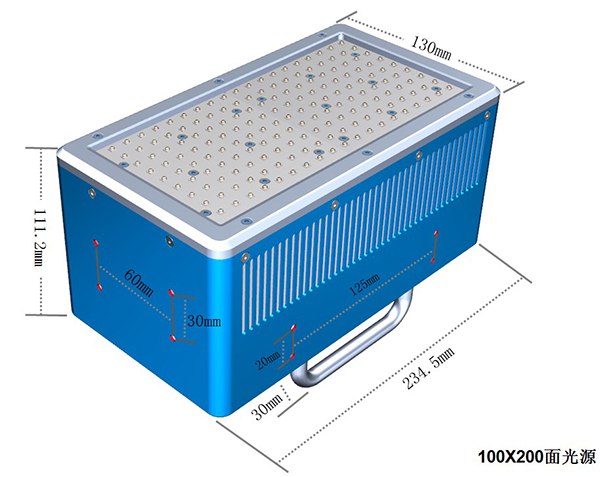

The type of optical lens UV curing machine can be divided into UV LED Spot Light Source, Large Area UV LED Surface Curing Light Source, and Linear UV LED Curing Light Source according to the cured area. For example, a 200*100mm UV LED Curing Systems is supplied to a manufacturer of high precision optical lenses in Guangdong, China. The first test result is OK. After some testing, the irradiation area, illumination intensity, curing time of the customized 100*200mm UV LED Curing Systems are very in line with the customer’s requirements. The customer promptly placed an order for two UV LED Curing machine after we quoted a reasonable price.