model no. :

365nm UV Curing LampBrand:

DSXUVport of dispatch :

ShenZhenPayment :

T/Toriginal region :

CHINALead Time :

15-30days

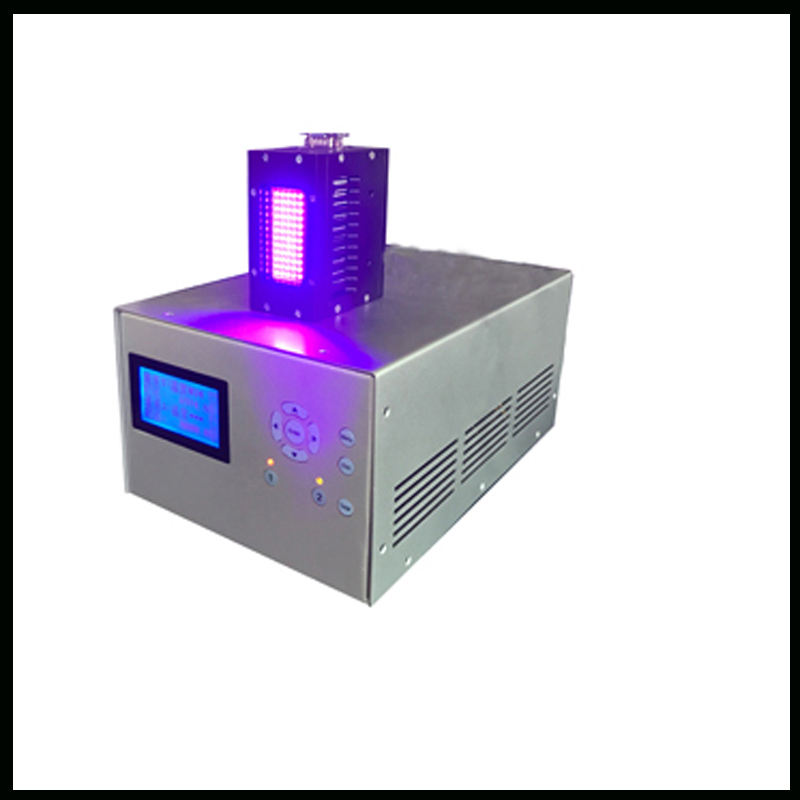

Energy Saving Bar Type LED UV Curing System for UV Ink.

The length of the irradiation head depends on your substrate and the width depends on the printing speed.This kind of Line Type LED UV Curing System can be used for UV ink, UV varnish and UV paint.It is suitable for flex printer, offset printer, flatbed printer and flexo printer. Different size and peak irradiance has different price.

Parameters of Small Area LED UV Curing Systems for Flexible Glue :

|

Long life span |

25000-30000H |

Energy saving |

save 80% electrical than Mercury lamp |

|

Environment friendly |

NO Mercury. NO Ozone. NO warm-up time.Low temperature |

UV output adjustment |

From 1%-100%. |

Irradiation Specification of Industrial UV LED Curing System Enhancing Industrial Curing Process :

| Curing area | wavelength | power intensity | print speed | cooled method |

| 60x25mm | 395nm | 12w/cm2 | 10m to 30m/ min | air or water cooled |

Note:The length of the irradiation head depends on your substrate and the width depends on the printing speed.This kind of uv led curing system can be used for uv ink, uv varnish and uv paint. It is suitable for flex printer, offset printer, flatbed printer and flexo printer. Different size and peak irradiance, different price.

|

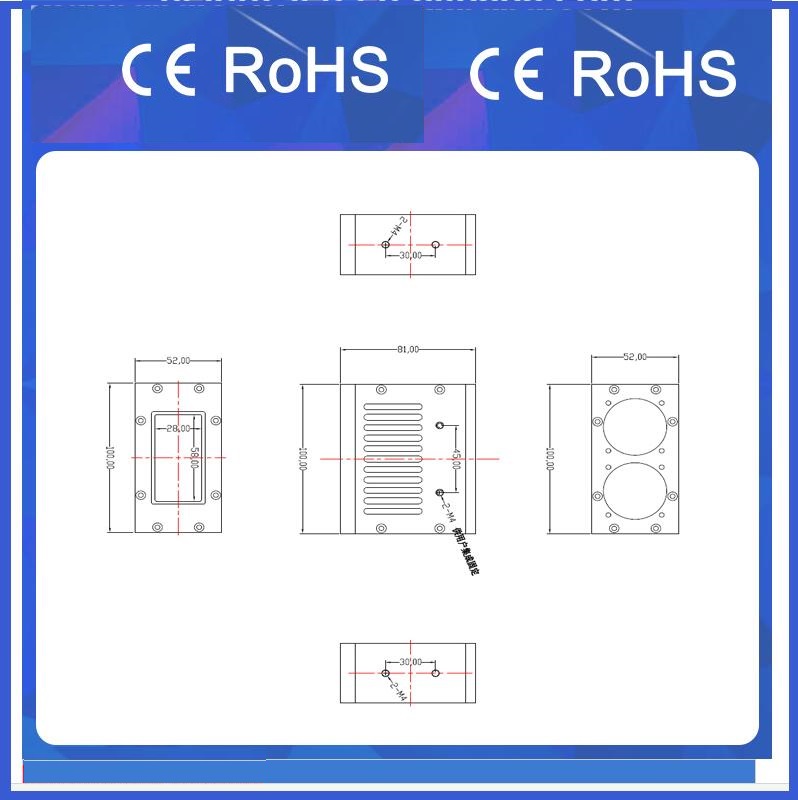

Controller Specification of Linear UV Curing Light Source Curing Screen Printing Inks : |

|||

|

Model |

DSXUV-II |

||

|

Channel |

Two |

||

|

The size of controller |

L200*W310*H150mm |

||

|

Terminal I/O |

Input |

Pedal switch & serial RS-232 communication signals |

|

|

Output |

serial RS-232 communication signals |

||

|

Cooling method of controller |

Air cooling |

||

|

Power supply voltage |

AC100~240V±10%(50/60HZ) |

||

|

Operation mode |

Touch Panel |

||

|

Ambient temperature and humidity |

Ambient temperature:-10℃—50℃ Relative humidity:25%—85%RH |

||

|

Dimming/Exposure control |

Digital Debugging,Manual exposure control,Foot control or timing control (0.1~9999S) |

||

|

Setting operation |

Using the operating switch is set,Power key parameter switch,RS-232 |

||

|

External Control |

External input |

Enter irradiation alone Irradiation stop input, Interlocking,All lights illuminated input,Query switch |

|

|

External output |

READY signal,Error signal,Warning Output,Busy output(Various skinhead),+5VOutput (indicator used) |

||

Product Advantages of Line Type 365nm UV LED Curing Machine Drying UV Ink:

1.Extra-long life: 25000h~30000h

2.Energy saving: save 80% electrical energy than Mercury lamp

3.UV output adjustment: From 1% to 100%

4.Multiple control modes : Constant current, pedal control, intelligent optical and manual modes

5: Photoelectric induction, instant on/off, no preheating required.

6: Low energy consumption, just 20% of the ordinary uv lamp

7: No mercury, No Ozone, eco-friendly

8: Cold light source, low temperature

9: Stable output, high uniformity.

10: Instant on/ off, no preheat required.

Air Cooling UV Solidify Machine Curing Mobile Phone Touch Screen

Air Cooling UV Solidify Machine Curing Mobile Phone Touch Screen

Air Cooling UV Solidify Machine, Emitting Window:104*25mm, is designed as a simple, low cost, small form factor air-cooled UV LED curing lamp for pinning and curing of inks, coatings and adhesives, mobile phone touch screen.

104*25mm Water Cooling UV LED Curing System

104*25mm Water Cooling UV LED Curing System

The WnnexCureTM EB168 UV Light Emitting Diode provides highest output power in an extremely medium mechanical package for high speed pinning and full cure applications. The EB168 UV LED Light Source is CE, RoHS, and REACH compliant.

Top Quality 365nm UV LED Curing Equipment Drying UV Glue

Top Quality 365nm UV LED Curing Equipment Drying UV Glue

100*100mm high power top quality power saving 365nm LED UV Curing Machine Curing UV Glue can be customized. You know 365nm is the best wavelength to cure UV glue.

365nm LED UV Curing UV Glue UV Curing Machine for Bonding

365nm LED UV Curing UV Glue UV Curing Machine for Bonding

Customized 365nm UV LED Curing System for lens bonding. UV LED Area Curing System can make glue curing, wavelength 365nm, rec area : 20*25mm, quickly, effective to cure.

High Power UV LED Dryer for UV Adhesive Curing System 30*120mm

High Power UV LED Dryer for UV Adhesive Curing System 30*120mm

High Power UV LED Dryer for UV Adhesive Curing System is 30*120mm, 365nm.

UV LED Curing System Customized UV LED Dryer for Printing Screen and Printing Dryer 395nm

UV LED Curing System Customized UV LED Dryer for Printing Screen and Printing Dryer 395nm

Curing Area of NEW High intensity 395nm light source UV LED Linear Curing system is 600*20mm and its Wavelength is 395nm.