UV LED Modules Chip is high intensity and high power. It is equipped with numbers of lights.

model no. :

High Intensity UV LED Modules ChipBrand:

DSXUVport of dispatch :

SHENZHENPayment :

T/Toriginal region :

CHINAUV LED Modules Chip, high intensity and high power, is equipped with numbers of lights.

Key Features of Customized UV LED Module :

- Best thermally conductive substrates: thick film silver layer on aluminum nitride, or DBC (directed

bonded copper) on aluminum nitride that enable the high-power density;

- Eutectic soldering process instead of silver epoxy for die attach, improving thermal conductivity;

- “Known Good Die”, good brand of UV chips that have been tested reliable with good statistics;

four wavelength ranges: 360 - 370nm; 380 – 390nm; 390 – 400nm; 400 – 410nm.

- Thermally stable and UV stable silicone for encapsulation that were selected based on extensive

experimental test data;

- Long history on packaging UV light source with rich experience and lessons.

Part Number Specification of Replaceable UV LED Modules Chip 365-395nm :

|

Part number |

Wavelength range (nm) |

|

MLUV64-360 |

360-370 |

|

MLUV64-380 |

380-390 |

|

MLUV64-390 |

390-400 |

|

MLUV64-400 |

400-410 |

Absolute Maximum Rating of High Intensity Ultraviolet LED Chip Curing UV Ink :

|

DC forward current (A) |

|

|

MLUV64-360 |

5.6 (0.7 per channel) |

|

MLUV64-380 |

10.0 (1.25 per channel) |

|

MLUV64-390 |

10.0 (1.25 per channel) |

|

MLUV64-400 |

10.0 (1.25 per channel) |

|

Power consumption (W) |

|

|

MLUV64-360 |

162 (2.5W per chip) |

|

MLUV64-380 |

295 (4.6W per chip) |

|

MLUV64-390 |

295 (4.6W per chip) |

|

MLUV64-400 |

295 (4.6W per chip |

|

LED junction temperature (°C) |

130 |

|

Operating ambient temperature (°C) |

50 |

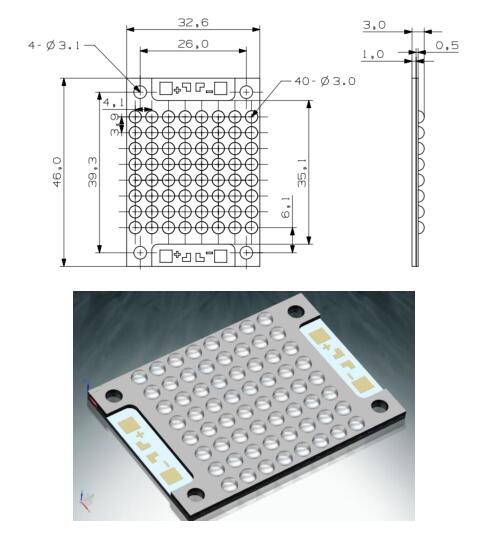

Mechanical Dimension of High Performance UV LED Chip :

|

Dimension (mm x mm x mm) |

46.0 x 32.6 x 3.0 |

|

Emitting area (mm x mm) |

31.7 x 30.3 |

Electrical Characteristics of UV LED Chip LED Module for UV Curing Systems :

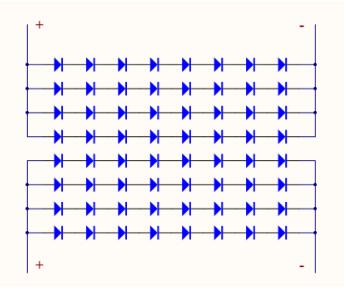

8 lines, each line has 8 LED chips connected in series; 8 lines are divided in 2 groups, each group has 4 lines;

the 4 lines in each group are connected in parallel at the ends.

Forward current (A)

Typical

Maximum

MLUV64-360

5.6 (0.7 per channel)

MLUV64-380

5.6 (0.7 per channel)

10.0 (1.25 per channel)

MLUV64-390

5.6 (0.7 per channel)

10.0 (1.25 per channel)

MLUV64-400

5.6 (0.7 per channel)

10.0 (1.25 per channel)

Forward voltage range (V)

Typical

Maximum

MLUV64-360

28.8 - 32.8 (3.6 - 4.1 for a die)

MLUV64-380

27.2 - 29.2 (3.4 - 3.65 for a die)

29.2 - 32.4 (3.65 - 4.05 for a die)

MLUV64-390

27.2 - 29.2 (3.4 - 3.65 for a die)

29.2 - 32.4 (3.65 - 4.05 for a die)

MLUV64-400

27.2 - 29.2 (3.4 - 3.65 for a die)

29.2 - 32.4 (3.65 - 4.05 for a die)

Power consumption range (watt)

Typical

Maximum

MLUV64-360

160 - 186 (2.5 - 2.9 for a die)

MLUV64-380

152 - 163 (2.38 - 2.55 for a die)

294 - 326 (4.6 - 5.1 for a die)

MLUV64-390

152 - 163 (2.38 - 2.55 for a die)

294 - 326 (4.6 - 5.1 for a die)

MLUV64-400

152 - 163 (2.38 - 2.55 for a die)

294 - 326 (4.6 - 5.1 for a die)

Connector 1

Connector 2

Optical Performance of Customized UV LED Chip 365-405nm :

|

Part Number |

Peak wavelength range (nm), @25°C, @3.5A (0.7A per channel, note 1 |

|

MLUV64-360 |

360 - 370 |

|

MLUV64-380 |

380 - 390 |

|

MLUV64-390 |

390 - 400 |

|

MLUV64-400 |

400 - 410 |

|

FWHM (nm) |

15 |

Radiant flux (W), @25°C, @3.5A

(0.7A per channel)

Min.

Max.

MLUV64-360

51 (0.8W per die)

64 (1W per die)

MLUV64-380

64 (1W per die)

77 (1.2W per die)

MLUV64-390

64 (1W per die)

77 (1.2W per die)

MLUV64-400

64 (1W per die)

77 (1.2W per die)

Radiant flux (W), @25°C, @3.5A

(0.7A per channel)

Min.

Max.

MLUV64-360

74 (1.16W per die)

95 (1.48W per die)

MLUV64-380

92 (1.44 per die)

113 (1.76W per die)

MLUV64-390

92 (1.44 per die)

113 (1.76W per die)

MLUV64-400

92 (1.44 per die)

113 (1.76W per die)

Notes: The peak wavelength is measured with an accuracy of ±1nm

Thermal Performance of Low Temperature UV Light Source Module Curing UV Coating :

|

Thermal Resistance (°C / W) |

0.08 |

Cautions of Industrial Specialized UV Light Module :

UV LIGHT These devices are ultraviolet LEDs. During operation, the LED emits high intensity ultraviolet (UV) light, which is harmful to skin and eyes.

UV light is hazardous to skin and may cause cancer. Avoid exposure to UV light when LED is operational.

Precautions must be taken to avoid looking directly at the UV light without the use of UV light protective glasses. Do not look directly at the front of the LED or at the LED’s lens when LED is operational.

High Power UV LED Module 31×19mm for UV Curing

High Power UV LED Module 31×19mm for UV Curing

Higt Intensity UV LED Module is good brand of UV chips that have been tested reliable with good statistics;Emitting area 31 x 19(mm x mm)

DSX-S03-UVLEDs 395nm UV LED Curing Modules UV Printing

DSX-S03-UVLEDs 395nm UV LED Curing Modules UV Printing

DSX-S03-UVLEDs Energy Saving 395nm UV LED Lamp Modules UV Curing is the use of quartz glass lens, better reliable. Metal material,best weather resistance,waterproof light.

High Power 20W 365nm UV LED Module Using CUN6GB1A Ultraviolet LED Light Beads

High Power 20W 365nm UV LED Module Using CUN6GB1A Ultraviolet LED Light Beads

High Intensity 365nm UV LED Light Module are designed for high current operation and high power output applications.

Customized UV Curing Machine Desktop UV Dryer Machine for UV Curing

Customized UV Curing Machine Desktop UV Dryer Machine for UV Curing

Desktop LED UV Dryer Machine for uv curing. PCB/PCBA Conformal Coating curing. SMT component protection and reinforcement. Medical instrument UV glue curing.

12-Inch 13-Slot Wafer Cassette 6061 Aluminum

12-Inch 13-Slot Wafer Cassette 6061 Aluminum

Product name: 12 inch 13 slot wafer basket Product Code:DSXUV-24G12-000-R1 Product process: Precision machining/ordinary oxidized black

Standard Vacuum Plasma Cleaning Machine with Best Quality and Best Price

Standard Vacuum Plasma Cleaning Machine with Best Quality and Best Price

Standard Vacuum Plasma Cleaning Machine can improve the mobility of ABS material, can improve the plasma hydrophilic pen tongue, can effectively make ink adsorption.