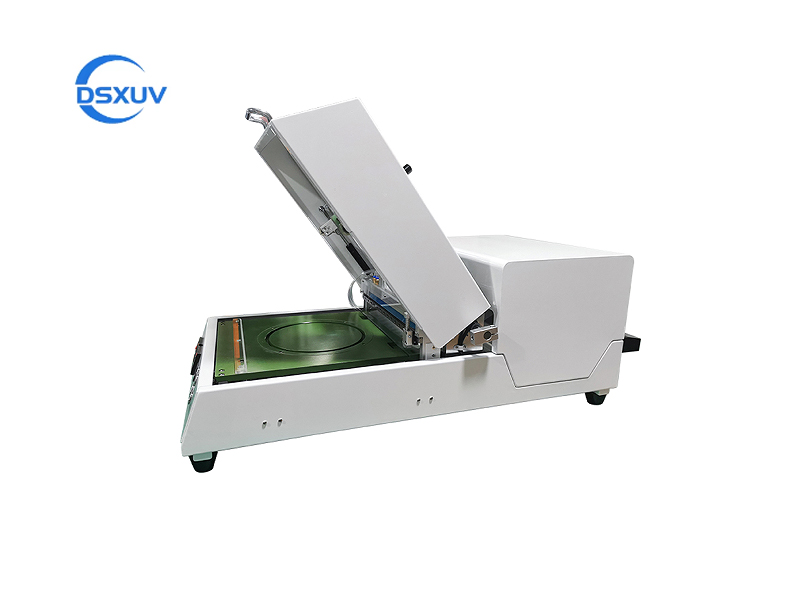

This Wafer Mounter Machine Compatible with Laminator and Grinding Functions, Heating Chuck, Adjustable Chuck, Equipped with Round Cutters and Cross Cutters, Suitable for Wafers of Different Thicknesses. The Film is Guaranteed to Have No Bubbles, No Residual UV film, No Curling Edges, and No Wrinkles.

model no. :

DSXUV-WM-6Brand:

DSXUVColor :

Whiteport of dispatch :

ShenzhenPayment :

100% T/T before shipmentoriginal region :

ChinaLead Time :

10days

The contact surface is coated with anti-static PTFE, effectively protecting the chip

Product name

Wafer mounter machine

Color

White

Model

DSXUV-WM8

Weight

100KG

Voltage

AC 220V

Frequency

50/60HZ

Power

500W

Atmospheric pressure

0.5-0.8MPA

Film

Blue film/UV film

Thickness of film

0.08-1.16MM

Heating Temperature

0-65

Pull film function

Manual

Film function

Manual

Film cutting method

Manual

Wafer thickness

100-200UM

Wafer Size

8inch

Fragment probability

1/10000

WPH

Film requirements

Size

1022*450*342MM

>60pcs

No particles, no fragments, no wrinkles

Customization is acceptable

Advantages and Quality Assurance:

1,Design to save UV film

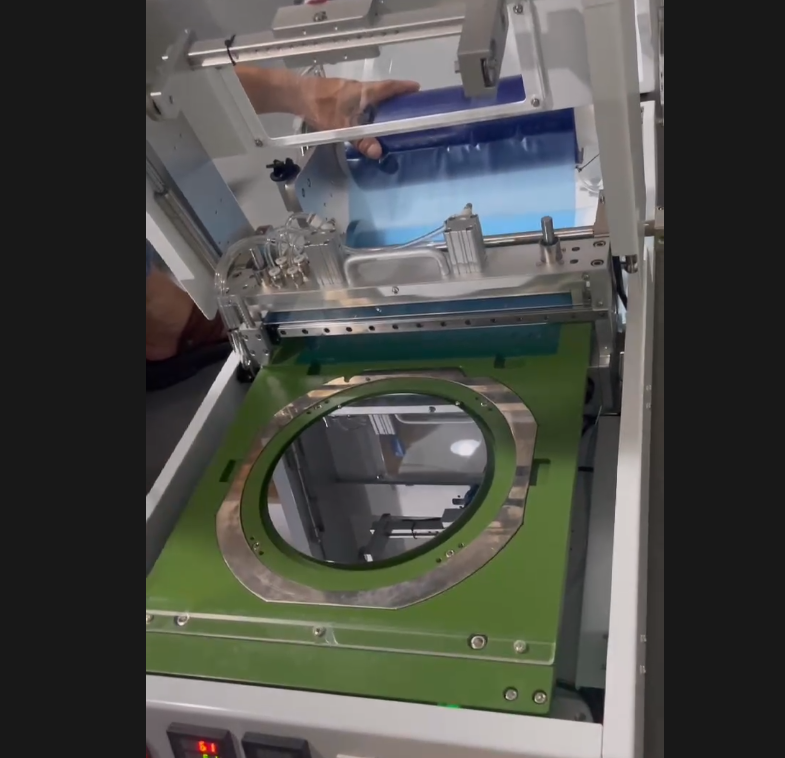

2,Micropore Chuck

3,Iron Buddha Dragon Surface

4,Small Size

5,Adjustable Roller Pressure

6,Suitable for multiple types of films

Product Efficacy:

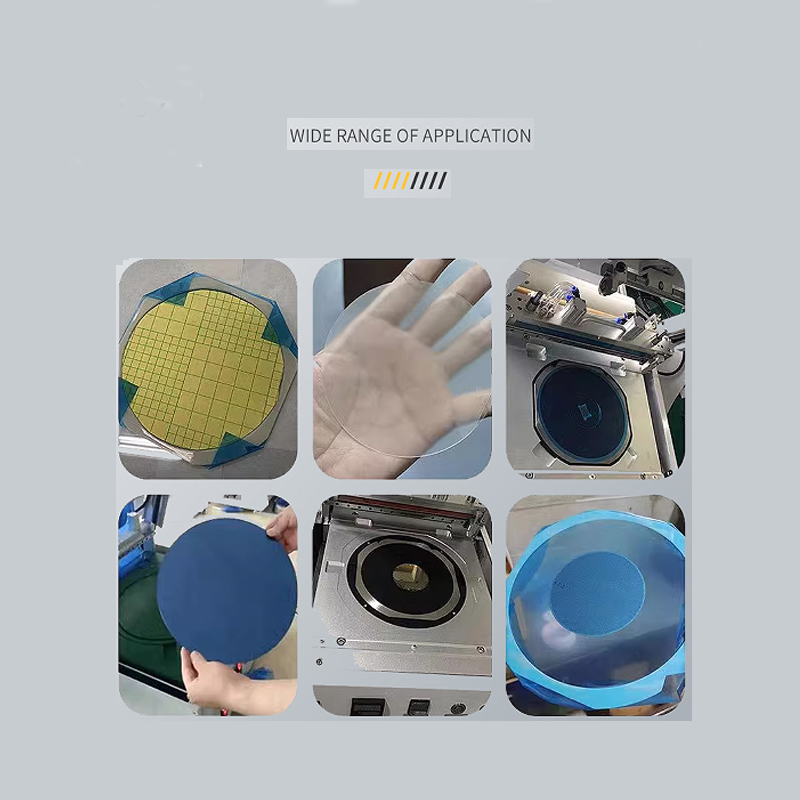

1,Compatibility: One body, compatible with cutting and grinding film functions

2,Heated and elastic film chuck design, suitable for wafers of different thicknesses

3,The pressure of the film roller can be adjusted to meet different film application needs

4,Equipped with circular and cross cutting knives for easy cutting and organization

5,Ionic air rod static removal device can be optionally selected to ensure no bubbles, smooth and burr free effect during the film application process

6,Teflon coated CHUCK ensures smooth film pulling without sticking

7,Vacuum adsorption system for tighter product adhesion

8,Micro porous design tray ensures vacuum adsorption function

9,The film is guaranteed to be bubble free, residue free, edge free, and wrinkle free

Wide Ring of Application:

1,Vacuum adsorption: Micro porous vacuum adsorption Chuck

2,Temperature controller: used to set the heating temperature

3,Vacuum gauge: table vacuum pressure gauge

4,Mode knob: For example, 6-inch 8-inch mode switch

5,Timer: Record the number of rotations of the circular cutter

6,Spring seat: cushion bounce of the chuck

7,Vacuum switch: Press the suction table chip to secure it firmly

8,Recycling roller: Recycling of release layer

9,Tray: Place SIC wafers (surface Teflon)

10,Side door: convenient for maintenance and film replacement

11,Film release roller: placement and fixation of film

12,Technical alarm: When the timer reaches the set value, the alarm will sound

13,Back cover: protection for the film placement area, can be opened and closed, convenient for operation and maintenance

14,Film roller: Roll the film to make it flat, wrinkle free, and bubble free

15,Cutting handle: ring cutting with a ring cutter

Product advantages and features:

Suitable for wafers of different thicknesses: The heated and elastic film design can adapt to wafers of different thicknesses

Adjustable pressure of film roller: The pressure of the film roller can be adjusted according to the requirements of the customer's product

Static electricity removal device: An ion air rod static electricity removal device can be optionally selected to ensure effective resolution of static electricity issues during the film application process

Easy to operate: Manual wafer laminating machines usually have automatic film pulling and laminating functions, reducing the complexity of manual operation and ensuring safe operation

Protecting wafers: Equipped with anti-static Teflon treated work plates and heating functions, it can effectively protect wafers from static electricity and damage

Efficient and stable: The equipment is designed with a floating worktable and precision guide rods to ensure stability and accuracy during the film application process. At the same time, the roller pressure can be adjusted, suitable for products of different thicknesses

Multifunctionality: Some manual wafer laminating machines also have automatic circular trajectory cutting of adhesive film, plasma anti-static function, etc., ensuring that the laminating film is smooth and free of burrs and bubbles

DSXUV 12inch Semi-automatic Wafer Mounter Film Sticking Machine

DSXUV 12inch Semi-automatic Wafer Mounter Film Sticking Machine

This equipment (lamator) is mainly used for 12 inch Si wafer BG film coating. No burrs, no bubbles. The wafer type is dummy wafer. This semi-automatic film sticking machine is suitable for applying film to products such as wafers, semiconductors, ceramics, and glass. It is a device used for film coating processing, specifically designed to precisely adhere thin film materials to the surface of wafers. It combines the characteristics of manual operation and automatic control, providing higher film application accuracy and efficiency while maintaining operational convenience.

Semiconductor Double Film Wafer Chip Laminating Machine

Semiconductor Double Film Wafer Chip Laminating Machine

Wafer Frame Film Mounter Machine can place UV tape and blue film at the same time for using.

Manual Wafer Laminating Machine Wafer Backgrinding Mounter 6 8 12 Inches

Manual Wafer Laminating Machine Wafer Backgrinding Mounter 6 8 12 Inches

6/8/12 inches Manual Wafer Laminator series is a fast and efficient sticking film machine, special designed for wafer, glass, LED PCB, and ceramic cutting process.

DSXUV-Wafer-M8 8 Inches Manual UV Tape Wafer Mounter

DSXUV-Wafer-M8 8 Inches Manual UV Tape Wafer Mounter

Wafer Frame Film Mounter is a machine that fixes a wafer and a ring together through a blue film or UV film.

DSXUV-Wafer-M6 6 Inches Semiautomatic Wafer Mounter For Dicing UV Film Cutting

DSXUV-Wafer-M6 6 Inches Semiautomatic Wafer Mounter For Dicing UV Film Cutting

Wafer Tape Laminating Machine is a machine that fixes a wafer and a ring together through a blue film or UV film.

Customized Glass Filter Semiconductor BG Film QFN Lamination Equipment

Customized Glass Filter Semiconductor BG Film QFN Lamination Equipment

DSXUV accept customized various glass material film laminating machine, various UV tape blue film BG film laminating systems.