6/8/12 inches Manual Wafer Laminator series is a fast and efficient sticking film machine, special designed for wafer, glass, LED PCB, and ceramic cutting process.

model no. :

Manual Wafer MounterBrand:

DSXUVport of dispatch :

ShenzhenPayment :

T/T 100% before shipmentoriginal region :

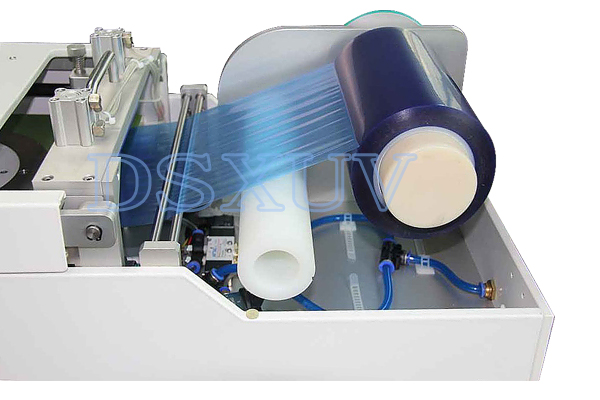

ChinaThe special saving film design can greatly reduce the film cost, and equipped with air flexible elastic (elastic adjustable) pressure roller and desk tray design. DSXUV Manual Wafer Lamination Machine not only can adapt to different thickness of the product, can also minimize the film stress, so that the product is not hurt. Easy to use, no training can be used immediately.

Mainly functions of Manual Wafer Lamination System:

1.Suitable for blue film, UV film, PET substrate film and double layer coating

2.Optional micro-porous tray for ultra-thin wafers

3.The heated and elastic plate design adapts to wafers of different thickness

4.Special film roller pressure adjustable design

5.Equipped with circumferential cutter and cross cutter

6.Optional electrostatic removal device for ionic wind rod

7.Small size, desktop display type

DSXUV Manual Wafer Mounter Type:

FM150: 6 inches wafer

FM200: 8 inches wafer

FM300: 12 inches wafer

Technical Specification of Wafer Mounting Machine:

|

Item |

Parameters |

Unit |

Noted |

||

|

FM150 |

FM200 |

FM300 |

|||

|

Wafer size |

3-6 |

3-8 |

3-12 |

inch |

Glass, ceramic, LED, PCB can be customized according to the size |

|

Minimize wafer thickness |

Normal plate: 150um, micro-porous plate: 100um |

um |

|||

|

Frame Dimension |

6 |

6/8 |

6/8/12 |

inch |

|

|

Plate heating temperature range |

Indoor temperature ~65 |

Indoor temperature ~65 |

Indoor temperature ~655 |

℃ |

|

|

Component replacement time |

<10 |

<10 |

<10 |

minute |

|

|

Machine dimension |

850(D)*390(W)*400(H) |

900(D)*450(W)*400(H) |

1000(D)*550(W)*400(H) |

mm |

|

|

Power supply |

AC220 |

AC220 |

AC220 |

V |

50~60HZ |

|

Compressed air |

0.5~0.8 |

0.5~0.8 |

0.5~0.8 |

MPa |

|

Saving Film Manual Wafer Laminating System:

Specially designed saving film structure, so that the manual laminating machine series become high saving film manual laminating machine. Compared with ordinary manual laminating machine, it can save about 15%, greatly reducing the cost of customers. The cost savings are even more significant when using expensive UV films now or in the future.

Suitable for ultra-thin wafer micro-porous film plate (optional):

Micro-porous plate is with unique air path design and elastic support structure, suitable for up to 100um thickness wafer, glass or ceramics. This structure is equipped with air flexible elastic, and elastic adjustable roller device can minimize the damage to the ultra-thin wafer during the lamination, greatly reduce the probability of breaking.

Anti-static surface treatment lamination plate with heating function and elasticity:

1.With heating and heating temperature range adjustable plate design, to ensure the film bonding effect can be adjusted to the ideal state.

2.The elastic plate disc adapts to wafers, glass or ceramics of varying thickness

3.The anti-static teflon treatment can not only minimize the static electricity generated during the lamination, but also effectively prevent physical scratches on the chip.

DSXUV 12inch Semi-automatic Wafer Mounter Film Sticking Machine

DSXUV 12inch Semi-automatic Wafer Mounter Film Sticking Machine

This equipment (lamator) is mainly used for 12 inch Si wafer BG film coating. No burrs, no bubbles. The wafer type is dummy wafer. This semi-automatic film sticking machine is suitable for applying film to products such as wafers, semiconductors, ceramics, and glass. It is a device used for film coating processing, specifically designed to precisely adhere thin film materials to the surface of wafers. It combines the characteristics of manual operation and automatic control, providing higher film application accuracy and efficiency while maintaining operational convenience.

Semiconductor Double Film Wafer Chip Laminating Machine

Semiconductor Double Film Wafer Chip Laminating Machine

Wafer Frame Film Mounter Machine can place UV tape and blue film at the same time for using.

DSXUV-Wafer-M8 8 Inches Manual UV Tape Wafer Mounter

DSXUV-Wafer-M8 8 Inches Manual UV Tape Wafer Mounter

Wafer Frame Film Mounter is a machine that fixes a wafer and a ring together through a blue film or UV film.

DSXUV-Wafer-M6 6 Inches Semiautomatic Wafer Mounter For Dicing UV Film Cutting

DSXUV-Wafer-M6 6 Inches Semiautomatic Wafer Mounter For Dicing UV Film Cutting

Wafer Tape Laminating Machine is a machine that fixes a wafer and a ring together through a blue film or UV film.

Customized Glass Filter Semiconductor BG Film QFN Lamination Equipment

Customized Glass Filter Semiconductor BG Film QFN Lamination Equipment

DSXUV accept customized various glass material film laminating machine, various UV tape blue film BG film laminating systems.

Customized Plastic Ring Wafer Film Mounting Machine

Customized Plastic Ring Wafer Film Mounting Machine

DSXUV accept customized various glass material film laminating machine, various UV tape blue film BG film laminating systems.