model no. :

DSX-new modelport of dispatch :

ShenzhenPayment :

T/T 100% before shipmentoriginal region :

ChinaLead Time :

10-15days

Parameters:

Model: DXSUV Chip Inverter

Method: Electric controlled servo motor

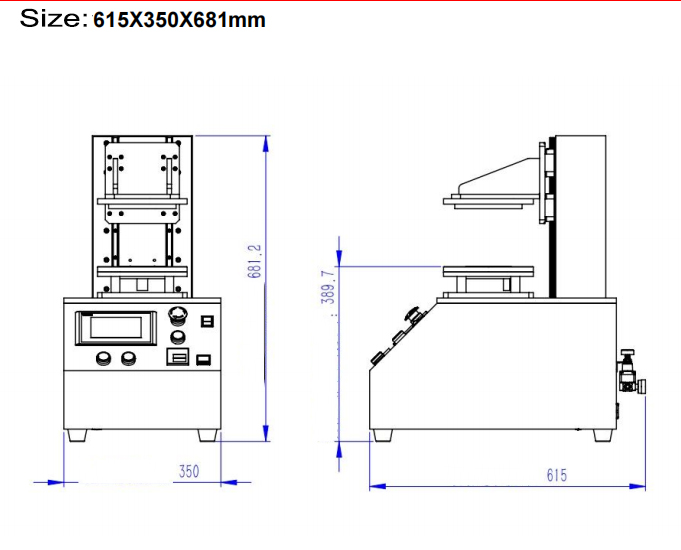

Compression stroke: 120mm+10mm

Heating system: Temperature controlled heating, heating range 0-70 degrees Celsius

Air pressure: 0.6-0.8Mpa

Total power: 950W

Machine voltage: 220V

Adsorption method: Vacuum adsorption

Film release method: manual

Product placement method: manual

The purpose of chip inversion machine:

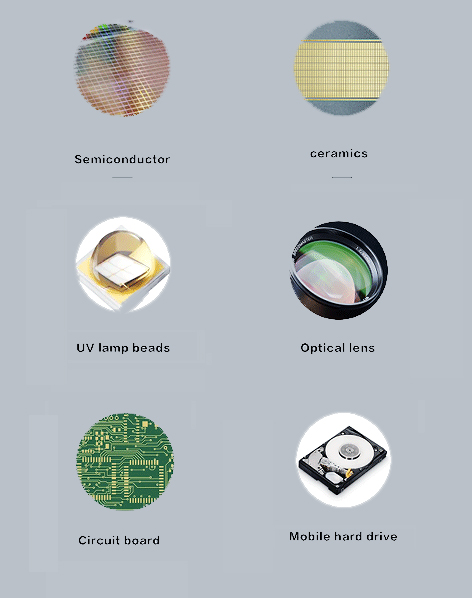

Packaging: In the process of chip manufacturing, a chip inversion machine can place a wafer containing completed chips onto the packaging layer (usually adhesive and packaging materials). This can protect the chip and provide electrical and mechanical connections.

Thin film transfer:

Chip inversion machines can be used to transfer wafers from one film to another (e.g. UV film, blue film, optical film, etc.). This can be used to manufacture devices with specific functions. Such as optical devices, sensors, and microelectronic components

Flip packaging:

In some advanced packaging technologies, a chip inversion machine can be used to invert the chip and package it in a specific position on another film. This method can achieve cleaning of products, thereby improving chip performance.

6 8 12 inches Semiautomatic Wafer Expander

6 8 12 inches Semiautomatic Wafer Expander

Blue Film Crystal Expander is used for expanding wafers after the singulation/dicing process

Manual UV Tape Expander Machine Die Matrix Expander

Manual UV Tape Expander Machine Die Matrix Expander

Manual Type Semiconductor Wafer Expander is widely used in expanding UV film on the crystal ring to facilitate the next operation.

Standard 8inch Wafer Expander for LED Semiconductor Chip

Standard 8inch Wafer Expander for LED Semiconductor Chip

Semi-Automatic Wafer Film Expander is used to evenly stretch the tape after the cutting process.

Semiconductor Wafer Chip Grip Ring Plastic Hoops Rings for Wafer Handling

Semiconductor Wafer Chip Grip Ring Plastic Hoops Rings for Wafer Handling

Plastic Wafer Expander Rings can be used in semiconductor and LED chip, consisted of inner and outer ring.

6inch Semiautomatic Wafer Expander for UV Tape Blue Film Expansion

6inch Semiautomatic Wafer Expander for UV Tape Blue Film Expansion

6 inch Semi-automatic Die Matrix Expander is widely used in wafer UV tape blue film expansion, frame ring to hoop ring, customized.

12inch Semiautomatic Semiconductor Wafer Die Matrix Expander

12inch Semiautomatic Semiconductor Wafer Die Matrix Expander

12inch Wafer Film Expander is a direct pressure grain expansion separation equipment, suitable for various wafer thicknesses.