2025-03-24 15:26:33

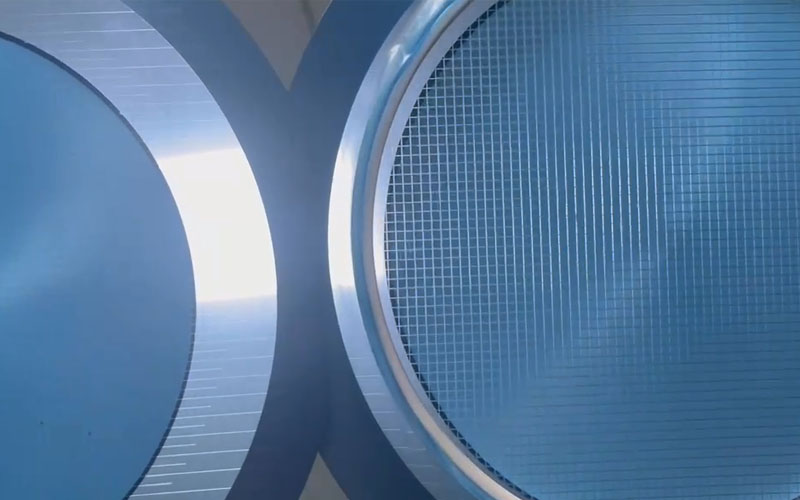

Wafer Expander System is a device used in the semiconductor industry to mechanically stretch the diameter of silicon chips. This process is called wafer expansion or wafer stretching. After the crystal cutting is completed, the spacing is very small and cannot be directly removed from the blue film or UV film. At this point, an wafer expansion machine is needed to increase the wafer size, such as: increasing the spacing from 200mm to 300mm or more, without affecting the integrity or quality of the wafer.

Wafer expander machine is a delicate process, and it is important to choose the appropriate expansion machine for the desired wafer size.

There are several types of wafer expander machine on the market, including manual expander system, semi-automatic film wafer extendion system, and automatic extender machine. Shenzhen deshengxing electronics Co., ltd, Specializes in producing manual expansion machines and semi-automatic expander machine. Manual expansion machines require operator intervention to gradually apply mechanical force and maintain control over the expansion process. The semi-automatic expander system is a machine that automatically cuts and pulls the film.

In addition, the expansion process should be carried out under controlled temperature and pressure, as different materials and device structures have specific limitations. It is necessary to monitor the magnitude of the force applied during the expansion process to prevent excessive stretching and damage to the wafer.

In short, using chip extenders for chip expansion is an important process in the semiconductor industry to increase chip size and improve production efficiency. Choosing the correct type of expander and following appropriate procedures, such as working in a clean room environment, monitoring force and temperature, and ensuring proper chip handling, is crucial for successful chip stretching and maintaining high-quality semiconductor manufacturing.