2023-01-10 18:03:35

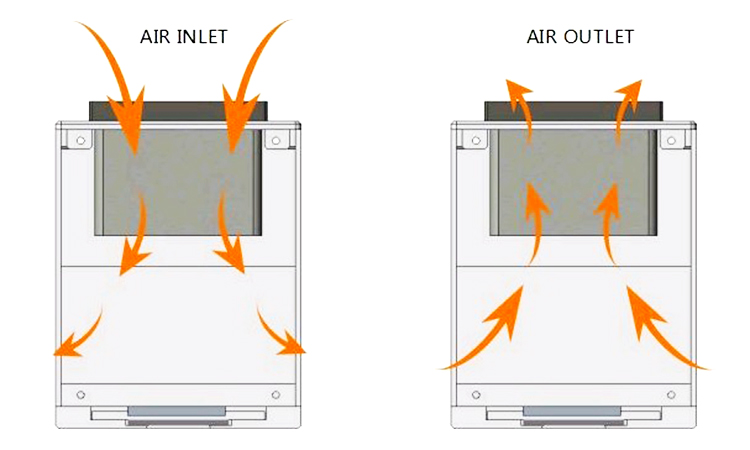

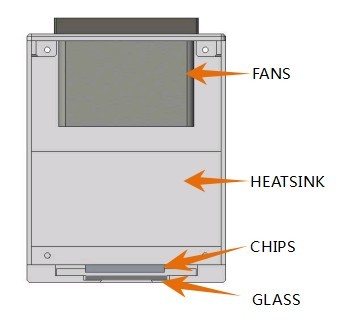

For UV LED Spot Light Source, Linear UV LED Curing Light, the heat dissipation mode is generally adopted fan cooling. When the fan is installed, there are two situations: one is to below air to the radiator, the other is to draw air in the opposite direction. The internal structure of conventional fan cooling irradiation head is shown below:

What are the characteristics of these methods? The answers are showed as below:

Characteristics of Below Air to the Radiator:

1.The air flow near the fan outlet is mainly turbulent and the local heat transfer is strong. It is suitable for the situation where the heating element is relatively concentrated. In this case, the main outlet of the fan must be aligned with the concentrated heating element.

2.When blowing, positive will be formed inside the device to prevent dust from entering the gaps in the device.

3.The fan will not be affected by the heat dissipation of the system. The fan works at a lower air temperature and has a longer service life.

4.Because the air blower has certain directivity, the air supply volume on the cross section of the entire enclosure will be uneven.

5.There will be a reflux and low speed zone near the fan HUB and between the parallel exhaust fans, resulting in poor heat transfer effect. It is advisable to keep the distance between the fan and the radiator at about 15mm.

Characteristics of Draw Air in the Opposite Direction:

1.Uniform air supply, suitable for heating device distribution is more uniform, more complex air duct situation.

2.The flow into the fan is mainly laminar flow

3.The service life of the fan is affected when the fan works under high temperature air flow in the outlet.

4.Negative pressure is formed in the equipment, and dust can enter through the gaps in the equipment.