2022-12-29 15:09:30

Bonding means attaching two objects together with a seal (often permanently)

Microtechnology involves various types of bonding processes

Used in IC packaging and printed circuit board assembly. Will not be covered in this lecture.

- Wafer bonding

- Wire bonding

- Flip chip bonding

Wafer bonding

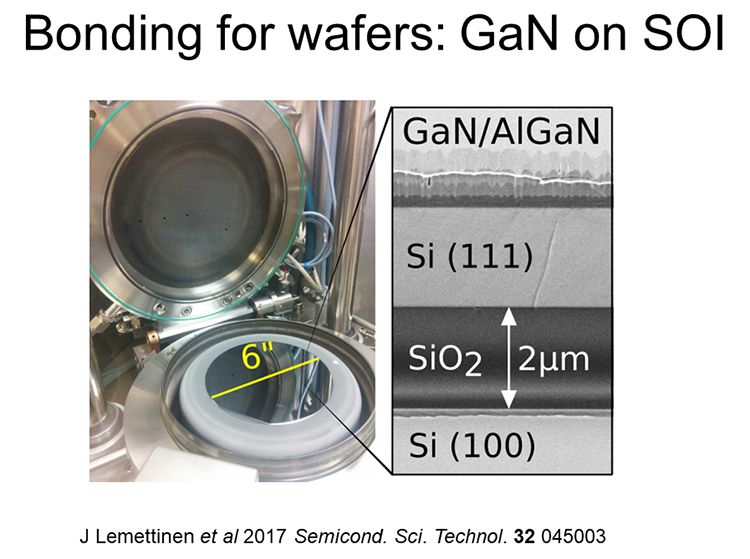

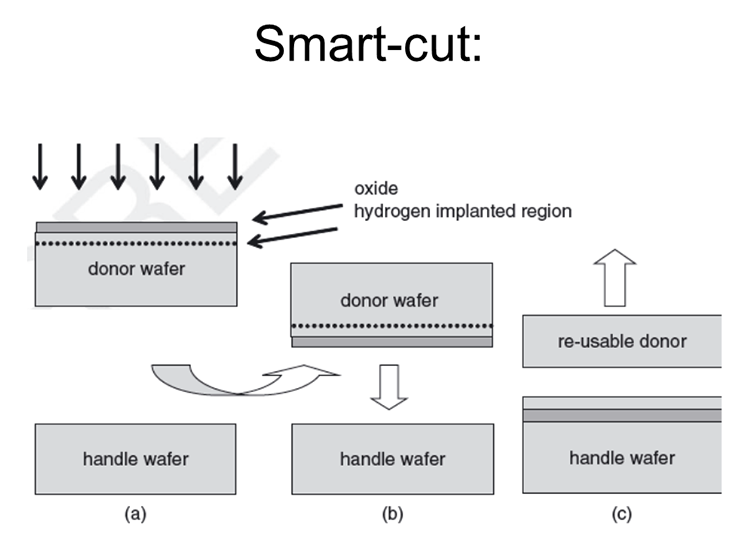

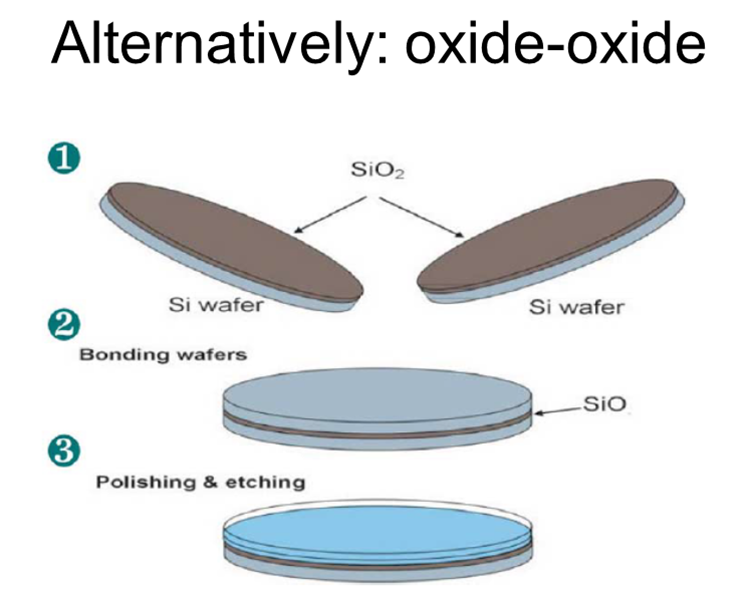

1: as a way to make advanced starting wafers SOI)

2: as a way to create complex 3D structures and cavities which create device functionality(chambers,channels,nozzles...)

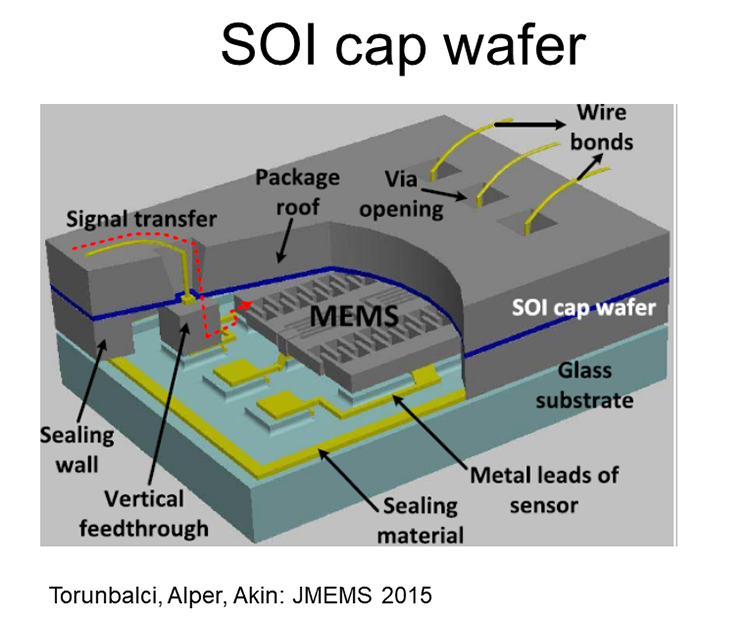

3: as a packaging method to create closed3environments(vacuum packages for resonators mirrors and IR devices)

Bonding requirements:

- smooth surfaces(on nm-scale)

- flat wafers (on cm-scale)

(intimate contact)

- no particles (voids larger than particles)

- matching CTEs (otherwise stresses)

- suitable surface chemistry (hydrophilic)

Wafer bonding procedure:

- particle removal

- surface chemistry modification

- (optional) vacuum pumping

- (optional) wafer alignment

- room temperature joining

- application of force/heat/voltage(optional) wafer thinning

Bonding considerations:

Bond properties

- What are the chemical bonds that will bond ?

- Exist naturally or formed by treatment?

- Bond strength ?

- Permanent vs. temporary ?

Bonding: materials

- Chemical compatibility

- Temperature tolerance

Bond formation temperature

Device operation temperature

- CTE(coefficient of thermal expansion) mismatch between materials

- Surface quality (roughness; waviness)

- Surface particles

Bonding: productivity considerations

- Availability of equipment (production tools have automated,cassette to cassette operation)

- Process compatibility (IC compatibility:temperature & contamination)

- Process yield

- Throughput

- Cost

- Maturity

Adhesive bonding

- surface cleaning

- spin coating of polymer

- initial curing (solvent bake)

- evacuate vacuum (optional)

- join the wafers

- final curing pressure and/or heat

Adhesive bonding benefits:

- temperatures around 100°C (>Tg)

- tolerant to (some) particle contamination

- structured wafers can be bonded

- low cost, simple process

Anodic bonding

- Anodic bonding (AB) = Field-assisted thermal bonding

- Glass and metals bonded

- Various glass types

Corning 7740 Pyrex glass most common for anodic bonding

CTE close to that of Si

- Annealing the glass before of after bonding can reduce stresses due to CTE mismatch

Fusion/direct/thermal bonding:

- Identical materials bonded

- No CTE problems

- Bonds naturally available

- Apply heat/pressure to enhance bonding

- Si-Si

- Glass-glass

- Polymer-polymer

Polymer thermal bonding (1):

Raise temperature above Tg

>softening

>intimate contact (hold long enough)>cool down below Tg

>Bond interface indistinguishable from bulk materials (because same bonds !)

Polymer bonding (2):

Softening by solvent surface treatment

>Intimate contact (hold long enough)

>Bonding of different polymers, too!

>In theory a room temperature process

>In practise difficult to control the thickness of the softened layer

C-SOl assignment

You are a SOl wafer manufacturer.

You would like to offer C-SOl wafers to your customers.

This brings about many technical issues as each design unique:

- SOl device layer thickness BOX-thickness

- cavity depths

- chip size

- film or no film at cavity bottom-what processes will be done afterwards ?

- ......

C-SOI commercial/contractua

You need to collaborate with the buyer more intimately:

- share designs

- share processing

- ship wafers around

- agree on inspections/quality

Develop a business model for C-SOI!

Output:

A PowerPoint presentation that you will present to potential MEMS manufacturers trying to presuade them to adopt C-SOl.

Audience includes engineers and bosses.