2021-03-19 17:22:00

High performance hard organic PCB substrate usually consists of dielectric layer (epoxy resin, glass fiber) and a high purity conductor (copper foil). We evaluate the parameters related to the quality of printed circuit board substrate, mainly including glass transition temperature Tg, thermal expansion coefficient CTE, heat-resistant decomposition time and decomposition temperature Td of substrate, electrical performance, PCB water absorption, electrical mobility CAF and so on.

Generally printed circuit board substrate can be divided into two types : rigid substrate materials and flexible substrate materials. The important type of general rigid substrate material is copper clad plate.

According to PCB board reinforcement materials are generally divided into the following types :

1.Phenolic PCB Paper Substrate

Because this PCB is composed of paper pulp, wood pulp, etc., it is sometimes also known as cardboard, V0 board, flame retardant board, 94HB, etc. Its main material is wood pulp fiber paper, through the phenolic resin pressure and synthesis of a PCB board.

Characteristics : don’t fireproof, can be punched processing, low cost, cheap price, relatively small density.

2.Composite PCB Substrate

This is also known as powder board, with wood pulp fiber paper or cotton pulp fiber paper as the reinforcing material. Glass fiber cloth is also used as the surface reinforcement material. Both materials are made of flame retardant epoxy resin.

There are single-side semi-fiberglass 22F, CEM-1 and double-side semi-fiberglass CEM-3, among which CEM-1 and CEM-3 are the most common composite substrate copper clad panels at present.

3.Glass Fiber PCB Substrate

Sometimes it is also called epoxy board, glass fiber board, FR4, fiberboard, etc. It is made of epoxy resin as a binder and glass fiber cloth as a reinforcing material.

Characteristics : high working temperature, little environmental influence, often used in double-sided PCB board.

4.Other PCB Substrate

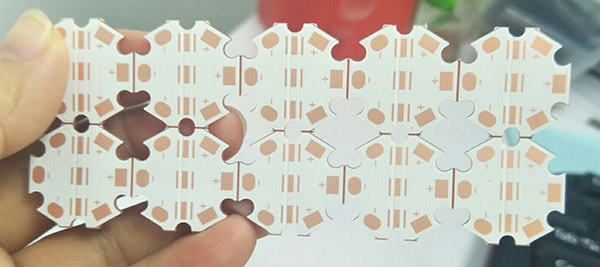

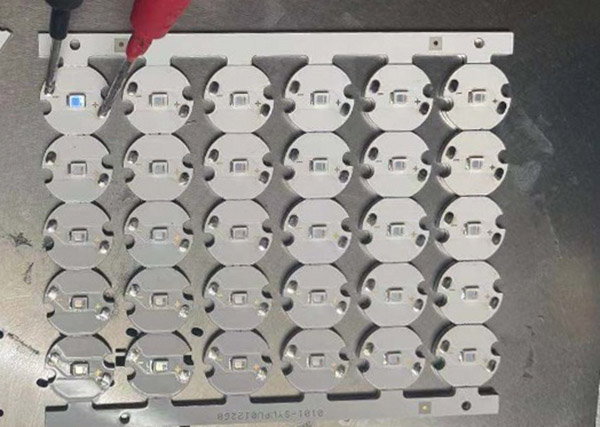

In addition to the three commonly seen above, there are also metal substrates and BUM.

Sub-base material technology and production, has experienced half a century of development, the world’s annual output has reached 290 million square meters. This development moment is driven by the innovation and development of electronics complete machine products, semiconductor manufacturing technology, electronics installation technology and printed circuit board technology.

China’s substrate material industry after 40 years of development, has formed an annual output value of about 9 billion yuan of production scale. In 2000, the total output of China’s mainland copper clad plates has reached 64 million square meters, creating an output value of 5.5 billion yuan. Among them, the output of paper-based copper-clad plate has ranked third in the world. But in the technical level, product variety, especially in the development of new substrate, there is a considerable gap with foreign advanced countries.