2021-03-13 11:16:54

Some camera module manufacturers used UV lamp irradiation curing before, the time is longer. In addition, the surface temperature of the camera assembly is higher after irradiation, which seriously affects the quality of their products. Therefore, they found us, Shenzhen Deshengxing Electronics Co., Ltd., to conduct special product testing.

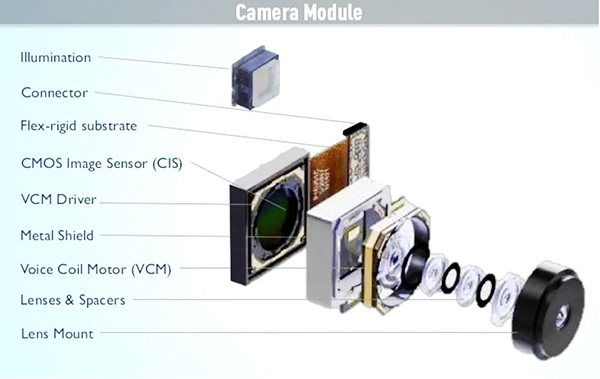

We knew that, in the production process of the security surveillance camera module, we need to use UV glue to fix the filters, lenses, CMOS components, etc. Because of using UV glue bonding, and the requirements of camera module is relatively high, it needs to use matched UV LED curing light source for curing and drying. And, because the volume of camera module is relatively small, we have given priority to choose Shenzhen Deshengxing Electronics Co., Ltd. UV LED Spot Light Source Equipment for product testing.

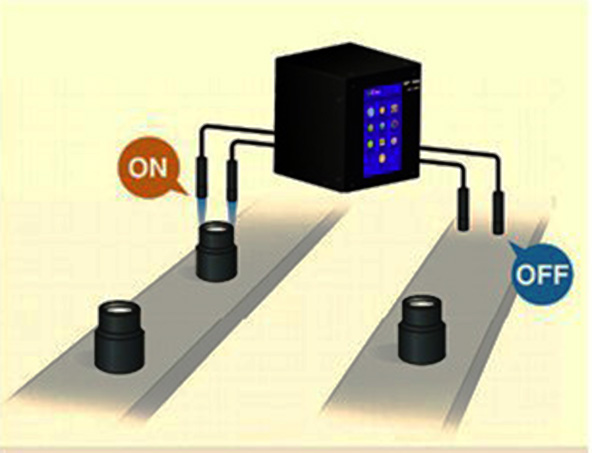

(overall / individual control)

After a series of comparative tests, the customer choose a custom UV LED spot light source equipment here for the curing UV glue. According to the test results, the surface temperature of the UV glue does not rise more than 5 ℃ after 5-10 seconds of UV irradiation, and the use of ordinary natural cooling irradiation head can meet the use requirements. Combined with actual using situation, we chose 1+4 UV LED spot light source curing machine to test. LED UV Curing Machine from Shenzhen Deshengxing Electronics Co., Ltd. not only greatly saves the curing time, but also the temperature of the camera module parts does not change basically. The curing effect of the UV glue is particularly good, which effectively solves the problems encountered by customers and achieves long-term cooperation opinions.

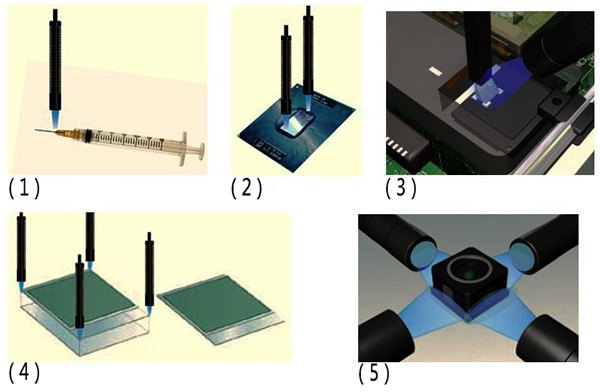

(1) medical products (2) electronics (3) components fixed

(4) LCD pre cured (5) camera module

(1) DVD/CD lens bonding irradiation

(2) lens and filter bonding irradiation

(3) digital lens IC bonding irradiation

(4) lens scoring bonding irradiation

(5) LCD/DLP optical

(6) liquid crystal main inlet seal and OLB enhancement

(7) small prism bonding

(8) hard disk, magnetic head bonding irradiation

(9) after core-adjusting, fiber optic connector parts bonding irradiation

(10) optical fiber color bonding irradiation

(11) photo-electric switch/special shaped parts bonding irradiation

(12) earphone voice coil bonding irradiation

(13) miniature motor parts bonding irradiation

(14) medical products bonding irradiation

(15) injecting needle fixation bonding irradiation

(16) compound bonding irradiation