2020-08-05 18:00:58

The cost structure of quartz lens mainly includes material, dimension size, dimension precision and process complexity.

1.Materials : common materials that can pass through UVC are synthetic quartz JGS1, fused quartz JGS2 and sapphire. The transmittance of synthetic quartz JGS1 is 1-3% higher than that of fused quartz JGS2 in the UVC 250-280nm band, and its price is several times higher than that of fused quartz JGS2. At present, the market use sapphire inferior packaging, experimental data shows that UVC 250-280nm band, sapphire transmittance than quartz is about 5-10%. Similarly, sapphire of superior and inferior grade is generally more expensive than quartz material, so sapphire is not suitable for the application of UV LED packaging and module.

2.Size : the smaller the volume, the lower the cost. Therefore, the original state of the material should be selected reasonably.

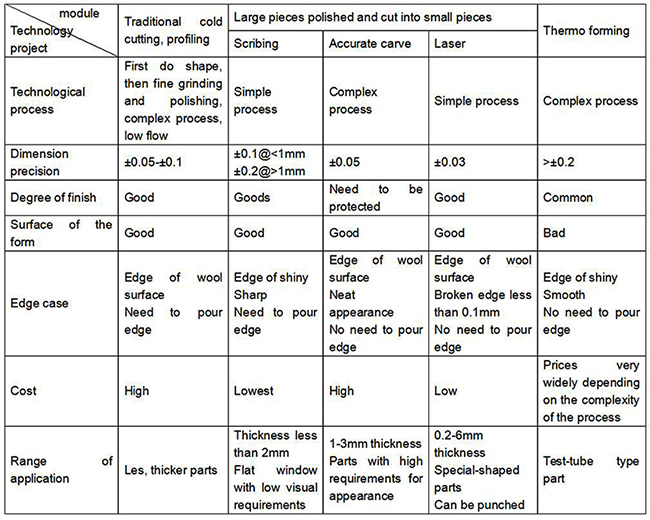

3.Process complexity : different processing techniques should be adopted for different shapes, and the corresponding cost impact is shown in the following table :

Lens coating can effectively increase the transmittance by more than 6%.

4.Parts precision requirements : mainly in the dimensions of precision, finish, surface, edge treatment of four aspects.

In a word, the cost of quartz lens can be effectively reduced by changing and controlling the material, shape structure, dimension precision and coating. Therefore, it is suggested that packaging and module manufacturers involve lens manufacturers in product design to control the cost of quartz lens.

Finally, let’s share the cases where the customer of the water purification module successfully reduced the price of quartz lens by 40%.

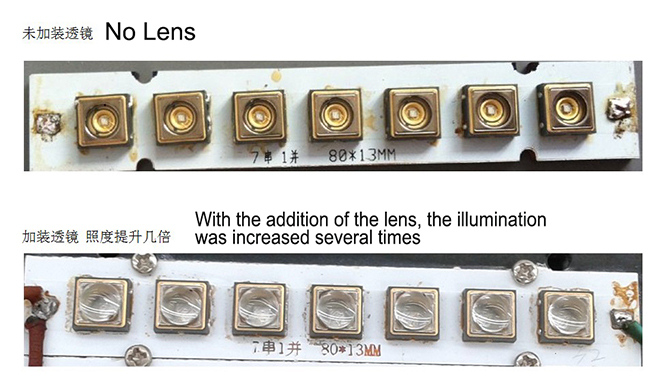

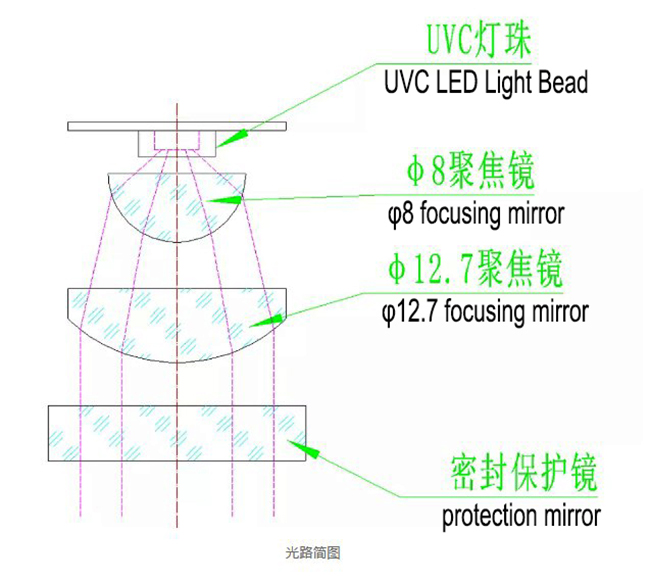

In collaboration with the client, the φ8 focusing mirror, φ12.7 focusing mirror and φ18 protection window were added to improve the intensity of light in the target area by collinating the light with a set of lenses to reduce scattering.

In addition, prices were successfully reduced by 40% through the following series of material and process controls.

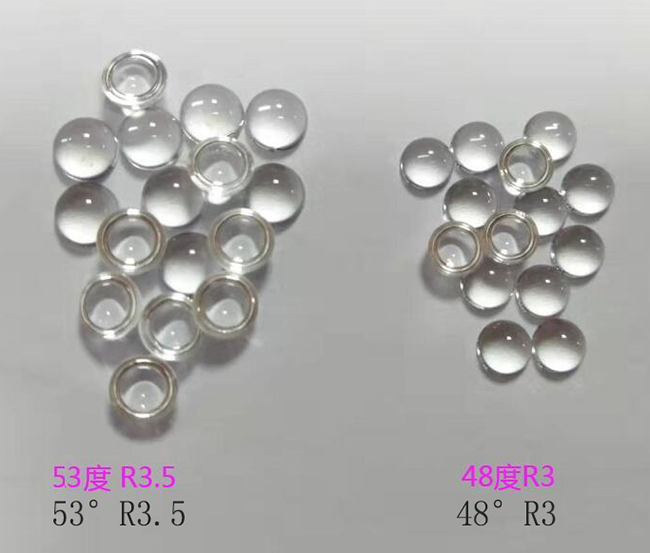

1.Change the shape of the lens and reduce the processing difficultly

2.Change lens size to reduce material consumption

3.Change the material type and reduce the material cost

4.Increased coating film, transmittance increased by 6%

5.Change lens dimension tolerance to reduce machining difficultly

Through the optical path design, material selection, changes in size, process control and increase coating, etc., to help customers reduce quartz lens costs and improve product performance, is also the hope later in the process of cooperation with customers, based on reasonable profit to help customers reduce costs, more rapid penetration of market in order to improve UV LED products.