2020-07-24 19:04:38

Application of UVC LED in flowing water

Water plays an important role in human circulation, so the purification and sterilization of drinking water is particularly important. Especially in this sudden public health crisis, UVC LED water purification field has won high market attention.

Technology changes life. With the continuous innovation and iteration of water purification technology and equipment, various application scenarios, such as medical treatment, education and other public areas, home and office environment, have greatly increased the demand for harmful microorganism inactivation. People's awareness of healthy drinking water is also constantly strengthened. UVC led over-flow sterilization technology, which has the advantages of high sterilization efficiency, convenient use and no secondary pollution, has become the primary solution for the current water treatment.

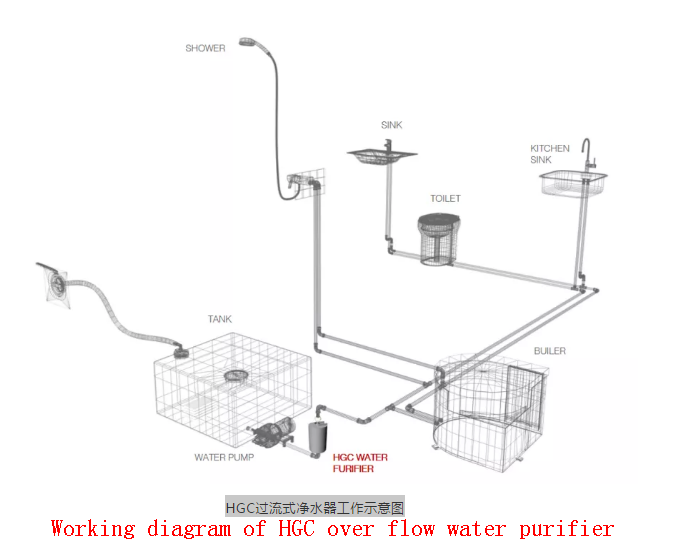

Structure and application scenarios of over flow water sterilization products

According to the application requirements of UVC LED related devices, UVC led over-flow water sterilization products are divided into five components: water inlet, water outlet, sterilization chamber, UVC LED module and main structure of the product. The sterilization chamber and UVC LED module are built into the main structure of the product, and the external power supply system is adopted for the product, and the water inlet and outlet are designed to connect in series into the water flow pipeline.

Light path design and material selection of sterilization chamber

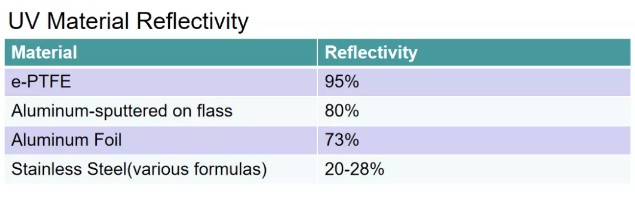

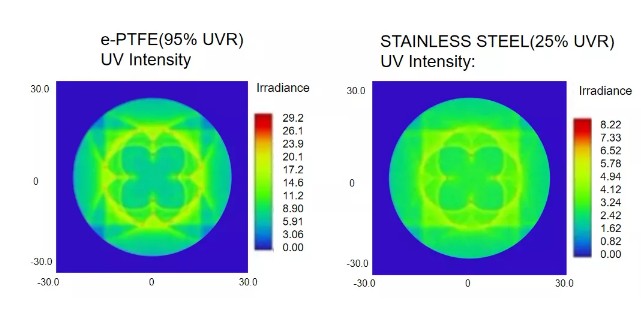

In 1878, human beings discovered that ultraviolet rays in the sunlight have the function of sterilization and disinfection. In 1906, people discovered quartz lamps with better performance of transmitting ultraviolet light. Quartz material is used because of the weak penetration of UVC. The transparent glass and transparent plastic UVC can not penetrate. In the cavity of over-flow water sterilization, quartz material is usually selected as light transmitting material, such as quartz lens, quartz tube, etc. PTFE (poly tetra fluoroethylene) or aluminum materials are generally selected as reflective materials.

Water is closely related to human health. Food grade materials should be used in the selection of products contacting with domestic water. The state has a special certification standard for food contact materials. Therefore, in the selection of UVC LED over-flow water sterilization products, not only the scientific matching of materials to UVC sterilization efficiency, but also the safety of materials should be considered. Our self-developed and designed over-flow water sterilization products use special reflective materials, pure quartz as lens and transparent pipeline, food grade silica gel as waterproof ring. The water-related materials of the products have passed food grade certification and obtained RoSH certification.

After selecting suitable materials, the design of light path should be considered when making sterilization cavity with specific structure. The angle between UVC propagating ray and pipe wall in the cavity pipeline should be greater than the total reflection angle θ of UVC at the interface between water and PTFE by making use of the refractive index difference of quartz, air and water, so that the UVC intensity in the water path can reach a higher value and make full use of UVC light source.

Improvement of overall sterilization efficiency of over flow water sterilization -- thermal management of UVC lamp beads

Over flow sterilization not only focuses on light path design and material selection, but also affects the final sterilization efficiency of the product

The first is the thermal management of UVC lamp beads. Since UVC over-flow water sterilization requires a one-time sterilization rate, the design light power of UVC module is high. The UVC lamp beads are usually high-density centralized patches. When working, a large amount of heat emitted by UVC lamp beads needs reasonable treatment, otherwise the light will quickly fade, leading to the decline of sterilization rate, HGC over water sterilization series adopts water cooling cooling system. During the use of the product, UVC module and flowing water continuously circulate and exchange heat to ensure that the junction temperature TJ of UVC LED is at a reasonable working temperature.

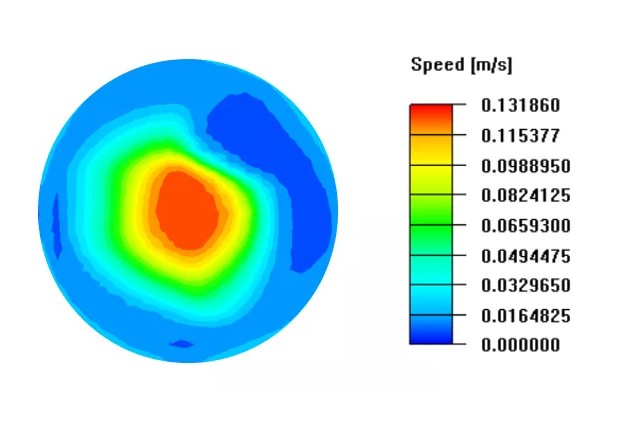

The second is the design of water flow in the pipeline. The essence of the product is that the water flows through the product and is irradiated by UVC. Therefore, the fluid needs to be scientifically designed. In principle, the water flow in the sterilization pipeline should be in the laminar flow model to avoid turbulence. The light intensity distribution should be designed according to the water flow density to ensure the highest sterilization efficiency.

There are also some factors that can affect the sterilization efficiency, such as air heating after UVC lamp beads work. The condensation will be generated after hot air contacts quartz lens, dew affects the transmittance of UVC rays in quartz lens. And the product design of some structural dead Angle are easy to scale and form eddy current, etc. These factors that are unfavorable to sterilization rate should also be considered in product design.

The over flow water sterilization product is a typical terminal application of UV LED with multi-disciplinary integration. The technology required for product design includes optical design, thermal design, material matching, parts assembly and many other technologies. The self-developed over-flow water sterilization and water purification terminal product series developed by HGC can achieve a flow rate of 2-20l / min and a sterilization rate of 99.99%, which is in the leading level of the industry.

At present, the world is still in the period of active epidemic prevention. We will continue to deepen the application of UVC-LED, and introduce High Power UV Ultraviolet LED Sterilization devices and solutions with higher cost performance, higher light efficiency and higher reliability, so as to contribute to the high-quality development of UVC industry.