2021-01-22 16:35:06

In cognition, we know that the curing speed of UV glue is very fast. In a certain wavelength of ultraviolet radiation can be dry within a few seconds. In actual use, the curing time of UV glue will be affected by a different factors. The factors affecting the curing time of UV glue are mainly divided into internal factors and external factors.

1.Internal factors

Internal factors are also decisive factors. Photo-initiator is one of the main components of any UV curing system, which plays a decisive role in the curing rate of UV system. Different UV glue formulations, the proportion of photo-initiator dosage is appropriate curing completely. On the contrary, it is slow and may not be cured.

2.External factors

UV curing adhesive curing rate, final curing depth and surface dry effect and UV light source, lighting time, material transmittance and other factors are also related, it is recommended to determine the specific curing time through the test.

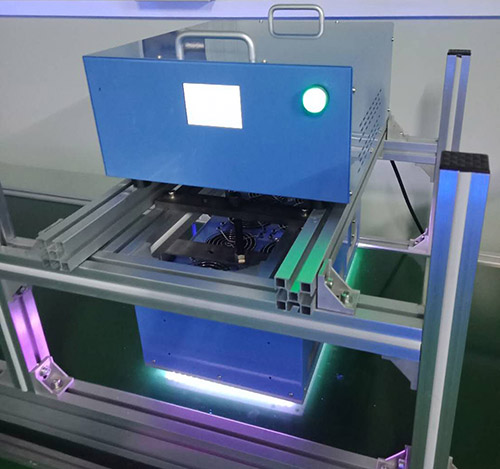

Related to the power of the ultraviolet curing lamp, high power curing polymerization is fast, otherwise the opposite. Under normal circumstances, UV glue is cured by UV curing lamp irradiation. Low wattage UV solidification systems curing time will be extended under irradiation. High wattage Ultraviolet lamp curing time will be shortened under irradiation.

It is also related to the transmittance of the material. The material is conducive to ultraviolet light penetration, which is conducive to fast curing speed. On the contrary, the curing time is extended. If UV penetration is difficult, it may not cure.