2021-01-30 12:06:46

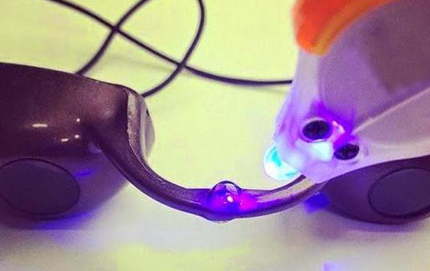

1.UV glue - application in medical supplies

One of the driving forces behind the growing use of UV-curable glues is the use of disposable items. UV glue can be used to attach hypodermic needles to syringes and IV tubes, as well as in catheters and medical filters.

2.UV shadowless - in the glass and handicraft, jewelry industry application

UV shadowless adhesive with its excellent optical and chemical properties, is widely used in glass industry, especially in the application of safety glass. Different from the traditional safety glass production time of about 20h, UV shadowless adhesive only seconds or a few minutes to complete the bonding process, greatly improve the production efficiency, shorten the production cycle. Additional, vitreous furniture also is important application field.

3.UV glue - applications in electrical and electronic industries

UV glue curing in the electrical and electronic applications of the fastest development, the main uses includes :

A.Adhesion and sealing of smart cards and conducting polymer display

B.Coating and sealing of terminal posts, relays, capacitors and micro-switches

C.Paste surface elements on printed circuit board (PCB)

D.Integrated circuit block bonding on printed circuit board

E.Fixation of coil lead terminals and bonding of parts

Similarly, the bonding of automotive industry components is often in this area, covering automotive light assembly, rear-view mirror and airbag components for bonding and fuel injection systems.

4. UV shadowless - application in optoelectronics and information industry

UV shadowless adhesive in the application of optoelectronics, information industry, this field with the continuous development of science and technology, has this huge potential, which mainly includes three consumer areas : digital optical disc manufacturing, optical fiber bonding and liquid crystal and polymer display.

UV glue in LCD manufacturing purposes are as follows :

Temporary fixation of photoelectric components, motherboard seal, port seal, the bonding of metal lead terminals, flexible sealing end, bare chip mount, homo-topic and film bonding, and FCOG cover coating.

In the computer hard disk manufacturing, the magnetic head and the folding work procedure is : a small amount of glue is added to the front end of folding piece tongue, and then by the central clamp head on the tongue glue place. With a certain intensity of ultraviolet light irradiation machine for a few seconds, so that the adhesive initial curing. Then take out from the automatic adhesive machine, after processing, put in the UV Curing Oven, in the set temperature heating curing, is a UV thermal curing double curing.