Supporting Square Iron Rings, Steel Ring Film Sticking, Ceramic Substrate Dedicated Film Sticking Machine, Green Anti-static Coating, No Bubbles, Adjustable Chuck Table

model no. :

DSXUV-WMDPCBrand:

DSXUVColor :

Whiteport of dispatch :

ShenzhenPayment :

100% before shipmentoriginal region :

ChinaLead Time :

15 days

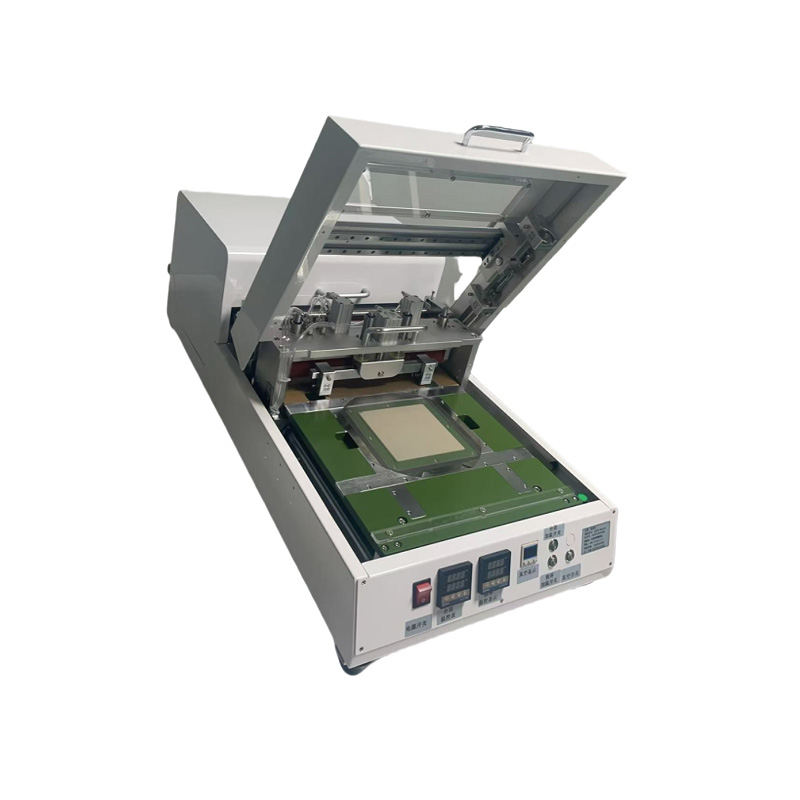

Ceramic substrate dedicated wafer laminating machine

No bubbles or burrs

Green anti-static coating

Teflon heating table plate

Micro porous vacuum adsorption

Support square steel ring film

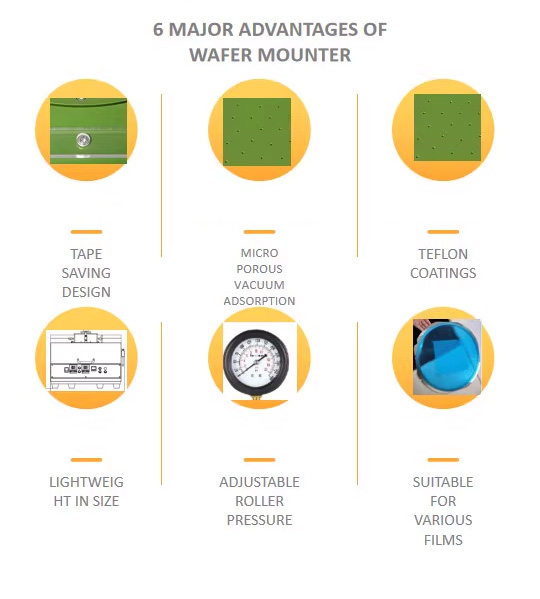

PRODUCTS DETAIL AND FEATURES

Adjustable elasticity of tabletop: Micro porous tabletop

Temperature controller: used to set the heating temperature

Vacuum gauge: Vacuum pressure display on the table

Vacuum switch: 4-inch, 6-inch, 8-inch vacuum switch

Temperature control switch: temperature on and off function

Recycling roller: Recycling of release protective film

Tray: Place wafers (surface PTFE)

Side door: convenient for maintenance and film replacement

Film release roller: setting and fixing of film

Transition roller component: transition of film

Technical alarm: When the counter value reaches the set value, the alarm will sound

Back cover: protection for the film placement area, can be opened and closed, convenient for operation and maintenance

Film roller: Roll the film to make it flat, wrinkle free, and bubble free

Cutting components: retractable cutting blade, safety protection

Cutting handle: the ring cutting handle of the ring cutter

Local advantages:

1- Adapt to ceramics and wafers of different thicknesses: Designed with a heated and elastic film coating platform, suitable for wafers and ceramics of different thicknesses

2-- The pressure of the film roller can be adjusted according to the requirements of the customer's product

3-- Protect the product, equipped with anti-static Teflon working disc and heating function

4- Efficient and stable, the equipment is designed with a floating worktable and precision guide rod to ensure stability and accuracy during the film application process. At the same time, the roller pressure can be adjusted to adapt to products of different thicknesses

5- Multifunctional, some manual wafer laminating machines have automatic circular trajectory cutting of adhesive film, plasma electrostatic function, etc., ensuring that the laminating is smooth and free of burrs and bubbles

DSXUV 12inch Semi-automatic Wafer Mounter Film Sticking Machine

DSXUV 12inch Semi-automatic Wafer Mounter Film Sticking Machine

This equipment (lamator) is mainly used for 12 inch Si wafer BG film coating. No burrs, no bubbles. The wafer type is dummy wafer. This semi-automatic film sticking machine is suitable for applying film to products such as wafers, semiconductors, ceramics, and glass. It is a device used for film coating processing, specifically designed to precisely adhere thin film materials to the surface of wafers. It combines the characteristics of manual operation and automatic control, providing higher film application accuracy and efficiency while maintaining operational convenience.

Semiconductor Double Film Wafer Chip Laminating Machine

Semiconductor Double Film Wafer Chip Laminating Machine

Wafer Frame Film Mounter Machine can place UV tape and blue film at the same time for using.

Manual Wafer Laminating Machine Wafer Backgrinding Mounter 6 8 12 Inches

Manual Wafer Laminating Machine Wafer Backgrinding Mounter 6 8 12 Inches

6/8/12 inches Manual Wafer Laminator series is a fast and efficient sticking film machine, special designed for wafer, glass, LED PCB, and ceramic cutting process.

DSXUV-Wafer-M8 8 Inches Manual UV Tape Wafer Mounter

DSXUV-Wafer-M8 8 Inches Manual UV Tape Wafer Mounter

Wafer Frame Film Mounter is a machine that fixes a wafer and a ring together through a blue film or UV film.

DSXUV-Wafer-M6 6 Inches Semiautomatic Wafer Mounter For Dicing UV Film Cutting

DSXUV-Wafer-M6 6 Inches Semiautomatic Wafer Mounter For Dicing UV Film Cutting

Wafer Tape Laminating Machine is a machine that fixes a wafer and a ring together through a blue film or UV film.

Customized Glass Filter Semiconductor BG Film QFN Lamination Equipment

Customized Glass Filter Semiconductor BG Film QFN Lamination Equipment

DSXUV accept customized various glass material film laminating machine, various UV tape blue film BG film laminating systems.