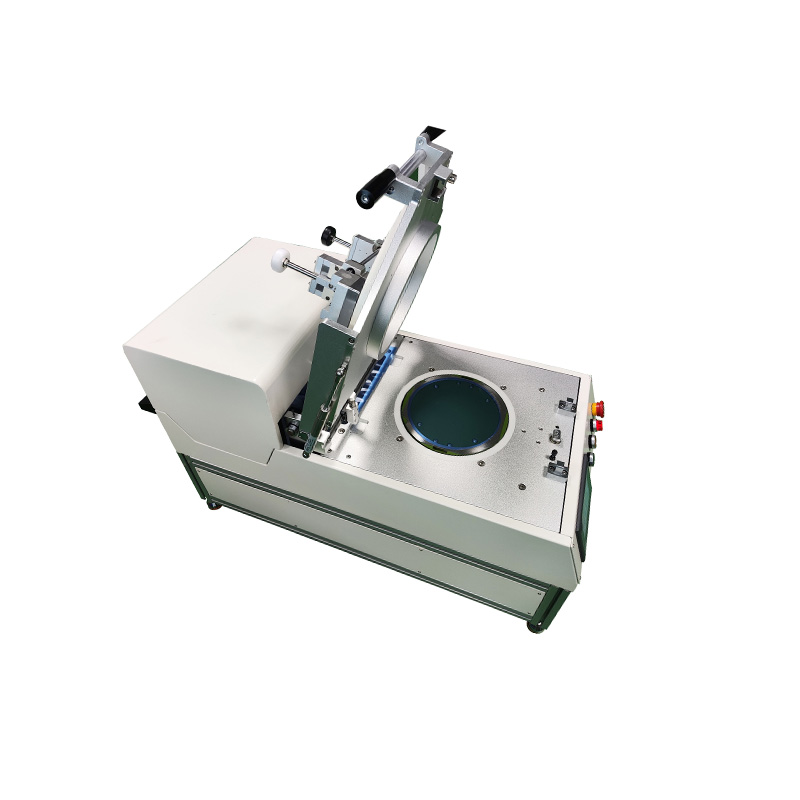

Manual or Semi-automatic, Uniform membrane expansion, tension control,Support disco iron rings

model no. :

DSXUV-WM6-BColor :

Whiteport of dispatch :

ShenzhenPayment :

100% T/T before shipmentoriginal region :

ChinaLead Time :

15 days

Wafer laminating machine Blue UV film wafer mounter machine BG QFN film laminator machine Customized glass filter semiconductor

1. Suitable for blue film, UV film, PET substrate film, and double-layer film.

2. Optional microporous film coating tray that can be applied to ultra-thin wafers.

3. The heated and elastic film coating tray design can adapt to wafers of different thicknesses.

4. Unique film roller pressure adjustable design.

5. Equipped with a circular knife and a cross cutting knife.

6. Optional ion air rod electrostatic removal device.

7. Small size, desktop placement type.

Micro porous film coating tray suitable for ultra-thin wafers (optional):

The micro porous design of the film coating platform, combined with unique air path design and elastic support structure, can be applied to wafers, glass or ceramics with a minimum thickness of 100um; This structure and the roller device equipped with air flexible elasticity and adjustable elasticity can minimize the damage to ultra-thin wafers during film application and greatly reduce the probability of breakage.

Anti static PTFE surface treatment film table with heating function and elasticity:

The table design with heating and adjustable heating temperature range ensures that the adhesive effect of the film can be adjusted to the ideal state.

The elastic platform can adapt to wafers, glass, or ceramics of different thicknesses.

The surface anti-static PTFE treatment not only minimizes the static electricity generated during film application, but also effectively prevents physical scratches on the chip.

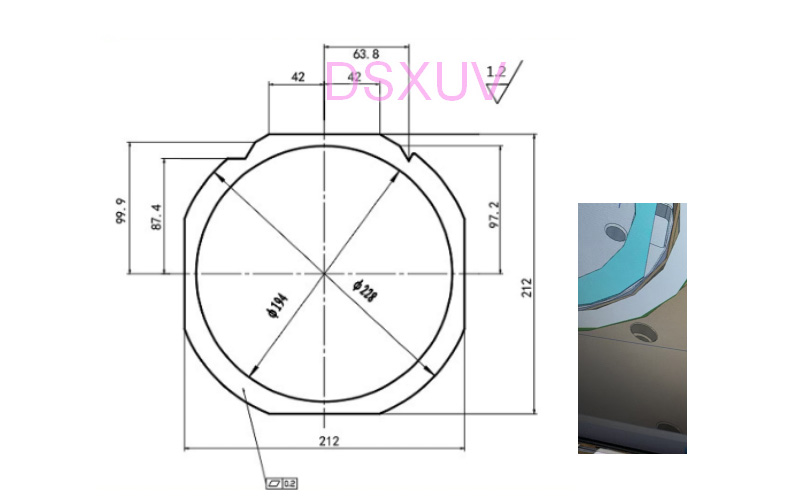

Suitable for standard 6-inch frame rings

|

Model |

DSXUV-WM6-B |

Size |

6-inch, ID228mm, OD194mm |

|

Overall size |

L1021×W490xH613mm |

Input power |

100-240V AC 50-6OHZ |

|

Total power |

500W |

Air pressure |

0.5~O.8Mpa |

|

Workbench lifting height |

0-30mm (PLC display screen set as needed) |

Type film |

Blue film/UV film (note: this machine is compatible with a film width of 270mm) |

|

Heating temperature of the tray |

O~1OOC |

Film thicknes |

0.06-0.17mm (For reference only) |

|

Film function |

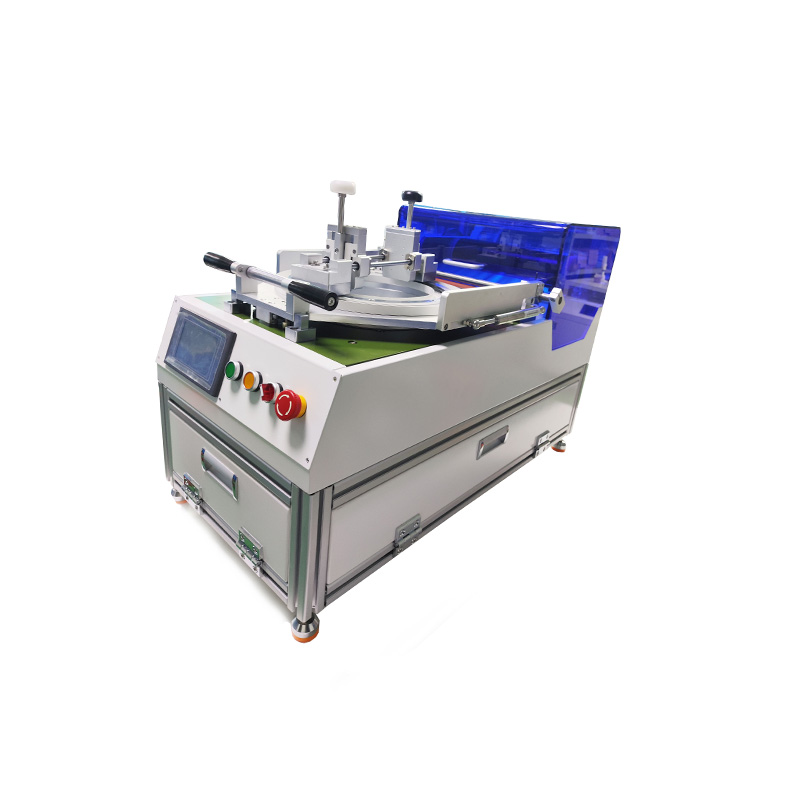

Manual loading and unloading, automatic lifting |

Film cutting function |

Manual rotating type |

|

Waste film recycling |

Automatic recycling of UV film release paper |

operating mode |

Touch screen combined with buttons to achieve manual/semi-automatic operation |

|

Function |

Without product stretch film, the film expands and tightens, |

Warranty period |

one year |

DSXUV 12inch Semi-automatic Wafer Mounter Film Sticking Machine

DSXUV 12inch Semi-automatic Wafer Mounter Film Sticking Machine

This equipment (lamator) is mainly used for 12 inch Si wafer BG film coating. No burrs, no bubbles. The wafer type is dummy wafer. This semi-automatic film sticking machine is suitable for applying film to products such as wafers, semiconductors, ceramics, and glass. It is a device used for film coating processing, specifically designed to precisely adhere thin film materials to the surface of wafers. It combines the characteristics of manual operation and automatic control, providing higher film application accuracy and efficiency while maintaining operational convenience.

Semiconductor Double Film Wafer Chip Laminating Machine

Semiconductor Double Film Wafer Chip Laminating Machine

Wafer Frame Film Mounter Machine can place UV tape and blue film at the same time for using.

Manual Wafer Laminating Machine Wafer Backgrinding Mounter 6 8 12 Inches

Manual Wafer Laminating Machine Wafer Backgrinding Mounter 6 8 12 Inches

6/8/12 inches Manual Wafer Laminator series is a fast and efficient sticking film machine, special designed for wafer, glass, LED PCB, and ceramic cutting process.

DSXUV-Wafer-M8 8 Inches Manual UV Tape Wafer Mounter

DSXUV-Wafer-M8 8 Inches Manual UV Tape Wafer Mounter

Wafer Frame Film Mounter is a machine that fixes a wafer and a ring together through a blue film or UV film.

DSXUV-Wafer-M6 6 Inches Semiautomatic Wafer Mounter For Dicing UV Film Cutting

DSXUV-Wafer-M6 6 Inches Semiautomatic Wafer Mounter For Dicing UV Film Cutting

Wafer Tape Laminating Machine is a machine that fixes a wafer and a ring together through a blue film or UV film.

Customized Glass Filter Semiconductor BG Film QFN Lamination Equipment

Customized Glass Filter Semiconductor BG Film QFN Lamination Equipment

DSXUV accept customized various glass material film laminating machine, various UV tape blue film BG film laminating systems.