At present, the spectrum of 365nm and 395nm peak wavelength is the main surface curing applied in the market . What kind of spectrum is needed to achieve the best effect depends on the glue or ink used. This need to consult the glue or ink supplier. In addition, because the wavelength of UV LED is much simpler than that of traditional UV lamp, if you want to achieve a better effect, it is better to ask your supplier if there is a model with single wavelength UV LED Curing Light Source when choosing UV glue and UV ink.

For UV LED Curing Light Source, UV LED energy (MJ / cm2) = UV intensity (MW / cm2) * irradiation time (s). Accurate control of UV LED intensity and exposure time can accurately control the UV energy of LED. For the control of irradiation time, our product has a built-in microprocessor, which can set the irradiation time and a variety of control modes, that is, on-off, without preheating.

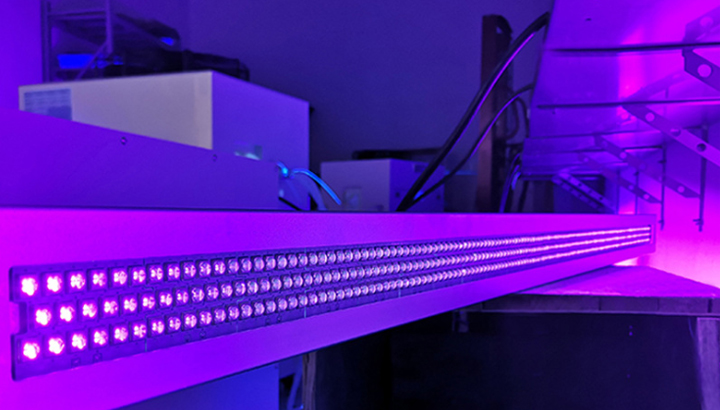

The UV intensity of UV LED Curing Dryer is very uniform, and the UV radiation intensity is considered in the design of products. For example, the curing light source of Heras, with imported high-power LED and high-tech optical lens, has unique software control program, and the radiation intensity range is from 1000MW / cm2 to 8600mw / cm2.

Advanced LED UV Curing Machine with safety lock, after setting the control mode, it can automatically turn off the light source to protect the safety of users. Taking Hera's curing equipment as an example, it uses cutting-edge heat dissipation chip technology and microprocessor functions to effectively control the temperature rise. This point needs special attention, the traditional mercury lamp temperature is not well controlled light source, will cause the bulb burst serious hidden danger.

It is difficult to prove this point directly by traditional technology, which is generally the accumulation of industrial experience. The general laboratory will not be equipped with a special machine, an unstable light source will seriously affect the relevant test progress. We have strict field test and many years of R & D experience to ensure the stable use of light source.