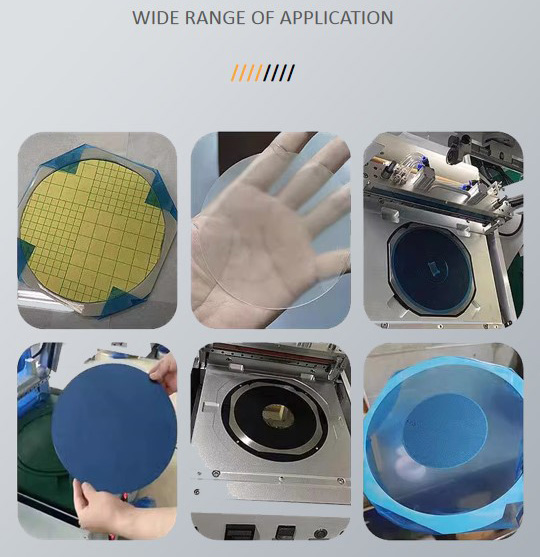

The wafer mounter machine is a key piece of equipment in semiconductor manufacturing. It is used to precisely laminate blue film/UV film onto thinned wafers, providing support and protection. It is applied in scenarios such as wafer fixation, pre-dicing support, and temporary bonding for 3D packaging.

Working Principle

1.Process: The robotic arm uses vacuum suction to pick up the wafer and press-fit it in the center of the pre-stretched film material. There should be no bubbles and particle contamination. In some cases, heating at 60-80°C is required to enhance the adhesion. The accuracy requirements are an offset ≤ ±50μm and a bubble diameter ≤1mm.

2.Key Components:

Material Suction Device: Anti-static silicone suction cups are used to ensure uniform suction and prevent damage.

Alignment System: High-precision CCD visual positioning (reaching ±5μm in 2025).

Temperature Control Module: Ensures the uniformity of low-temperature heating.

Usage Guide:

1. Pre-treatment: The wafer should be free of fragments and cracks. The height of the Ink dot should be < 25.4μm, and the trench depth of the etched wafer should be ≤10μm.

2. Film Material Selection: Commonly, blue film with an adhesion of 80-95μm is used. For ultra-thin wafers, low-stress UV film is used. Store the films according to regulations.

3. Operation Specifications: Run the machine without load to calibrate the alignment system. After laminating, let the wafer stand for 5 minutes before transferring.

4. Abnormality Handling: For bubbles, roll them with a dust-free roller. In case of offset, clean the suction cups and calibrate the CCD. If there is continuous offset, check the lubrication of the guide rail.

Technological Progress in 2025

1. Multi-size Compatibility: Quick-change pallets are available to support mixed–line production of 6/8/12-inch wafers, enabling efficient switching.

2. Intelligent Adjustment: AI algorithms optimize parameters, achieving a yield of 99.7% and reducing manual debugging.

3. UV Film Adaptation: A new UV irradiation module is added to support the switching of photocleavable film materials.

Maintenance and Safety

Regularly clean the equipment, check the suction cups and CCD lenses, calibrate the temperature control module, and replace vulnerable parts in a timely manner.

Ensure reliable grounding, avoid touching moving parts and high-temperature areas to prevent electric shock, mechanical injury, and burns.