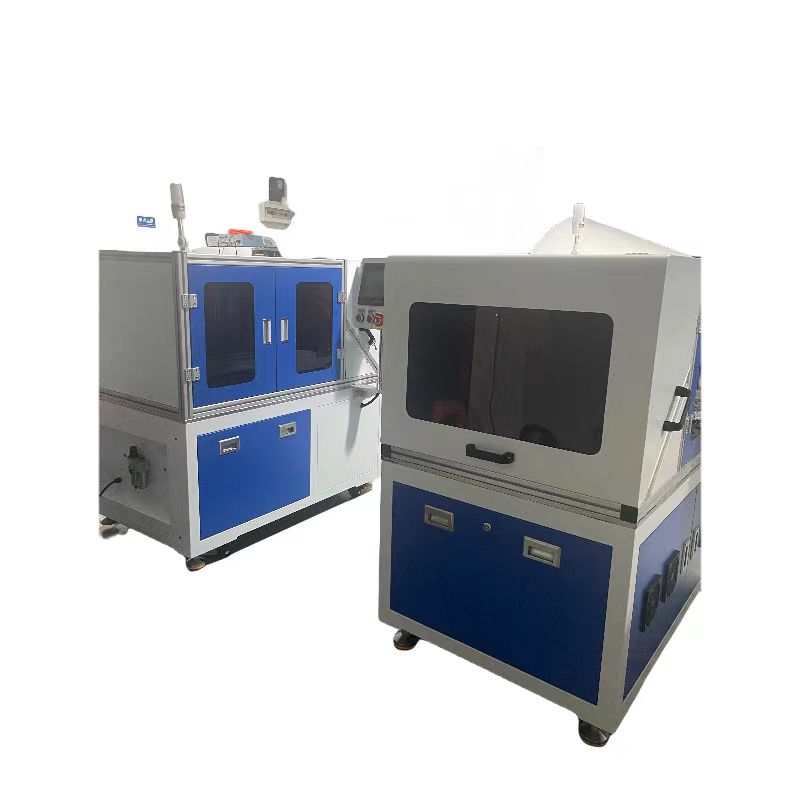

A semi-automatic film laminating machine is a film sticking equipment that combines manual operation and automatic control features. It can provide high film sticking accuracy and efficiency while maintaining ease of operation. This type of equipment is typically suitable for various industries, including electronics, communications, semiconductors, photovoltaics, etc., and is used to attach protective or explosion-proof films to product surfaces. Here are some detailed knowledge about semi-automatic wafer mounter machines:

Application areas: Semi auto wafer mounter machine are widely used in industries such as electronics, communication, and semiconductors for applying protective and explosion-proof films. In the photovoltaic industry, they are also commonly used in the manufacturing process of solar panels.

Operation process: When operating the semi-automatic film wafer laminating machine, the first step is to check whether the fastening bolts of the equipment are loose and clean all components on the machine. Then, adjust the glue and check whether the functions of the equipment are normal. After starting the machine, it is necessary to master the speed adjustment of the drum, temperature control of the drum, and temperature control of the drying channel. During the film application process, it is necessary to strictly control the speed and temperature of the equipment to ensure the quality and efficiency of the film application.

Maintenance: The semi-automatic wafer laminator machine requires regular maintenance, including checking the fastening bolts of the equipment, cleaning machine components, adjusting glue, etc. During the operation, pay attention to safety and avoid getting clothes and long hair caught in the machine to prevent accidents.

Technical features: Semi automatic film laminating machines usually have high efficiency, ultra quiet, and other characteristics. They use a rolling process to ensure no bubbles and high film sticking accuracy. Some high-end models are also equipped with user-friendly touch screen operation, making the operation more convenient and flexible.

Applicable products: The semi-automatic film sticking machine can be applied to various products, such as wafers, semiconductors, ceramics, glass, etc. They can handle wafers of different sizes, ensuring a tight fit between the film and the wafer to protect the wafer surface from contamination, oxidation, or other damage.

In summary, semi auto film wafer linamiting machine is an important production equipment that can improve film sticking efficiency and quality, reduce production costs, and is relatively easy to operate and maintain.