2024-07-05 15:02:58

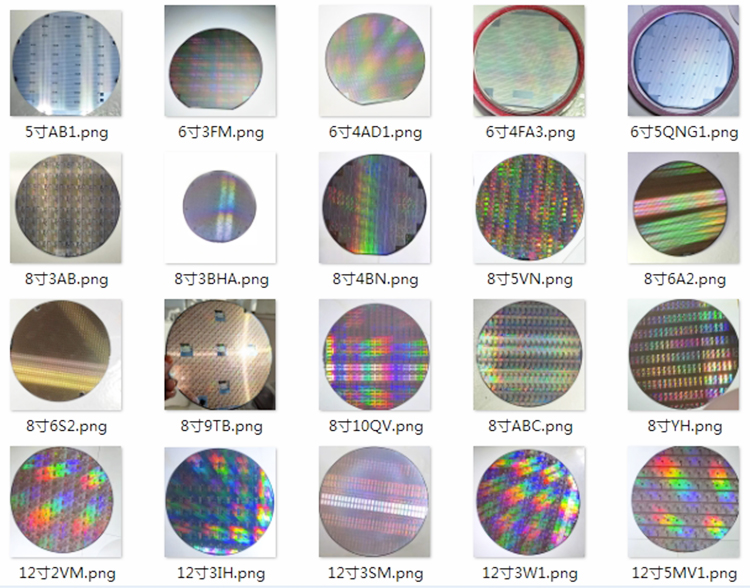

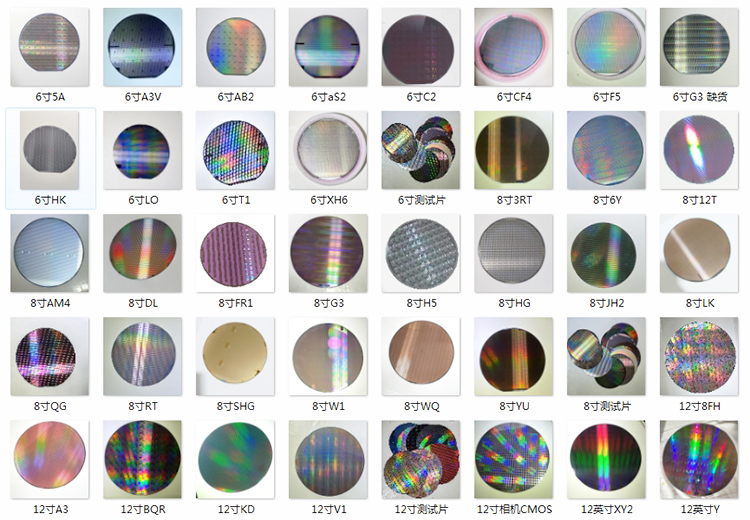

Dummy Wafer

Dummy means fake, not real. Generally, there are no graphics, or only a few layers of graphics. Main application for:

1.It is used for commissioning and calibration of semiconductor equipment to ensure that the equipment is in the best condition before the official production.

2. When introducing a new process or adjusting an existing process, dummy wafer chips are used for testing and optimization to reduce the risk of mass production pieces.

Test Wafer

The test wafer (engineering wafer) has a complete process flow, including a variety of graphics and structures of the wafer.

Main applications:

1.In the process of introducing new chip products, test pieces are used to verify and optimize the manufacturing process of new products, and finally achieve mass production.

2.When there are process problems with the production wafers on the production line, the corresponding DOE test is performed to improved the process.

Mass Production of Wafers

Mass production wafers are used to produce semiconductor devices that need to be shipped to customers. Strict quality control is carried out in the production process of mass production wafers to ensure that products meet customer requirements.

Why divide these types of wafers?

Mainly from the cost and importance of consideration. Cost / Importance: mass production wafer > test wafer > dummy wafer. Mass-produced wafers are to be shipped to customers and are the economic lifeblood of the entire company, so it is necessary to ensure that mass-produced wafers complete the production task with high quality and quantity. Process parameters and process flow are relatively fixed. Any changes must be 100% secure. Therefore, some low-cost and flexible dummy wafers and ENG wafers are derived to avoid the waste of mass production wafers!

DSXUV long-term supply of various wafer test wafer, dummy wafer. Welcome to consult!