model no. :

Dummy Waferport of dispatch :

HKPayment :

TT100%original region :

CNLead Time :

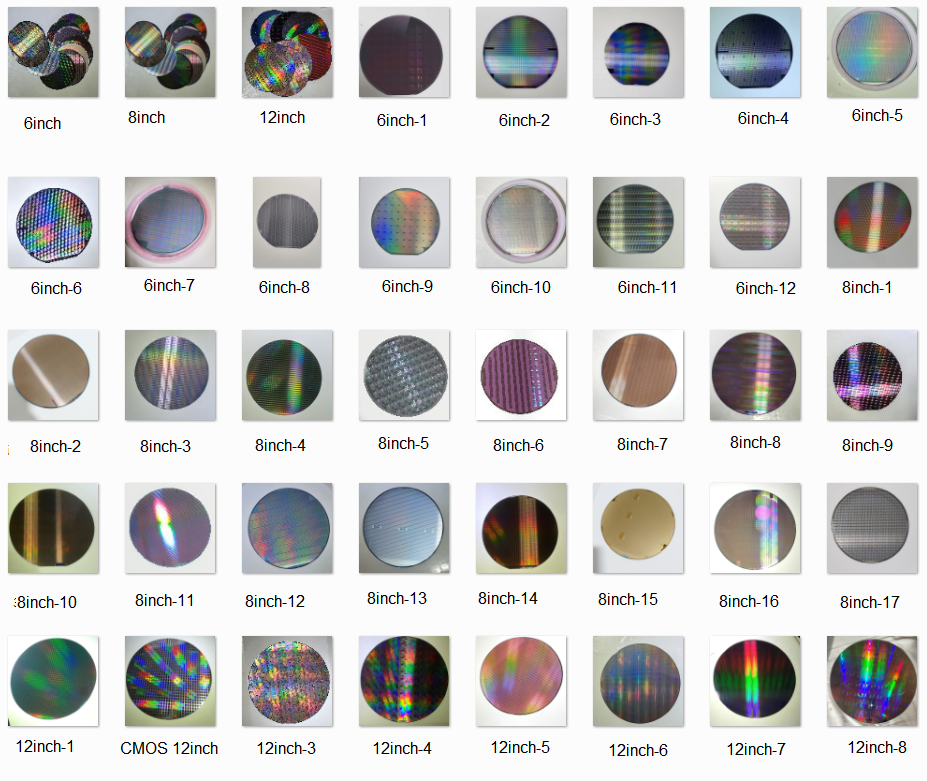

3daysWe Provide a Variety of Wafer Products to Meet Your Needs – Inquire!

6''Dummy Wafer

8''Test Wafer

12''Calibration Wafer

Probe Wafer

Monitor Wafer

Wafer Standard

Process Control Wafer

Metrology Wafer

Reference Wafer

Interposer Wafer What are the specifications of wafers?

Wafers come in various specifications and types. Here are some common wafer specifications:

1. Diameter: Wafer diameter is one of the most commonly used specifications. Common diameters include:

- 200mm: Also known as 8-inch wafers.

- 300mm: Also known as 12-inch wafers.

- 150mm, 100mm, 75mm, 50mm, etc.

2. Thickness: Wafer thickness is typically controlled and adjusted during the manufacturing process. Common thickness ranges include:

- 650μm: Common in earlier processes.

- 550μm, 450μm, 380μm: As technology advances and processes shrink, wafer thickness decreases.

- Ultra-thin wafers: In some advanced processes, wafer thickness can be much less than traditional thickness, reaching below 100μm.

3. Substrate Material: Wafers can be made from various substrate materials. Common materials include:

- Silicon (Si): The most common wafer substrate material, widely used in semiconductor manufacturing.

- Silicon Carbide (SiC): Used in the manufacturing of high-power electronic devices and optoelectronic devices.

- Gallium Nitride (GaN): Used in the manufacturing of LEDs and high-power electronic devices.

- Sapphire (Al2O3): Used in the manufacturing of optoelectronic devices.

4. Structure Type: Wafers can also be classified based on their structure, including:

- Silicon-on-Insulator (SOI): Wafers with a certain thickness of insulating layer, commonly used in high-performance integrated circuit manufacturing.

- Stacked Wafers: Wafer layers stacked together for 3D packaging and integration.

- Composite Wafers: Wafers integrating different materials to meet specific application requirements.

These are just some common wafer specifications and types. In reality, there are many other specifications and types available to meet the requirements of different application fields.

4 Inch Wafer Iron Hoop Wafer Frame Ring for UV LED Wafer Mounter

4 Inch Wafer Iron Hoop Wafer Frame Ring for UV LED Wafer Mounter

4 inch Iron Ring Wafer Frame is strong hardness, resistance to bending, good stickiness and durability, widely used in semiconductor packaging, film, cutting, adhesive process bearing appliances.

8inch Single Wafer Frame Shippers

8inch Single Wafer Frame Shippers

Single flex frame shippers design for 4" (100mm), 5" (125mm), 6" (150mm), 8" (200mm) and 12" (300mm) wafers.

Anti-static Silicon 6-inch 25 Slot Crystal Boat Box Octagonal Box Frame Ring Shipping Box

Anti-static Silicon 6-inch 25 Slot Crystal Boat Box Octagonal Box Frame Ring Shipping Box

Semiconductor specific 6-inch PP wafer boat box/anti-static flower basket 25 wafer packaging box, both horizontal and vertical transportation storage box, 6-inch octagonal box

Wafer Frame Cassette 12 Inches 13 Cells

Wafer Frame Cassette 12 Inches 13 Cells

Wafer Cassette Wafer Chip Frame Box With Blue Film Lron Rings Storage Standard 12 Inches 13 Cells Wafer Carrier

Wafer Carrier White Transparent

Wafer Carrier White Transparent

8-Inch Silicon Wafer Carrier Black/White Transparent PP Material Wafer Shipping Box