2021-09-24 16:54:33

Take NICHIA NWSU333B UV LEDs as an example, the same for other UV LED welding.

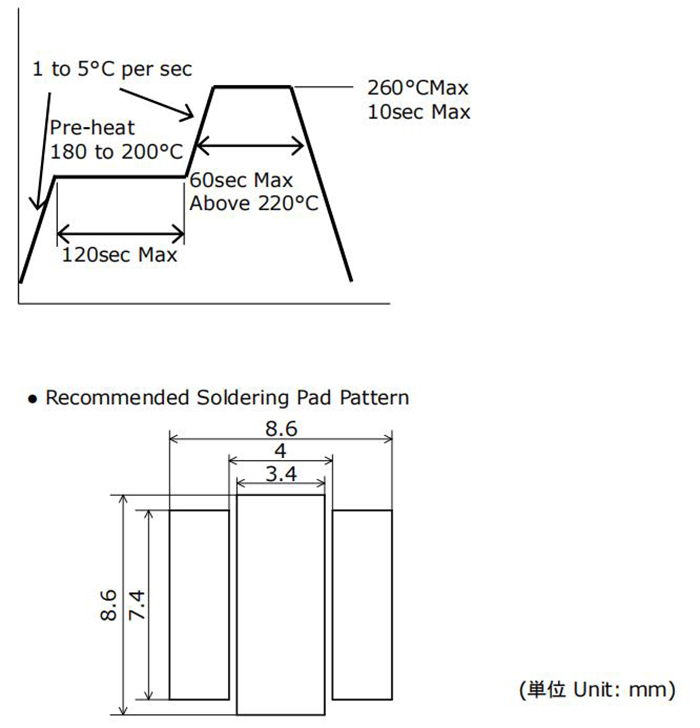

Recommended reflow soldering condition (lead-free solder)

1.This LED is designed to be reflow soldered to a PCB. If dip soldered or hand soldered, NICHIA will not guarantee its reliability.

2.Reflow soldering must not be performed more than twice.

3.When the LEDs are cooled from the peak reflow temperature, ensure that the cooling is performed very gradually to avoid excessive stress on the LED (e.g. causing cracks in the solder joints). ensure that sufficient preliminary verification is performed to ensure that there are no issues with the chosen reflow soldering conditions/process.

4.During reflow soldering, the heat and atmosphere in the reflow oven may cause the optical characteristics to degrade. In particular, reflow soldering performed with an air atmosphere may have a greater negative effect on the optical characteristics than is a nitrogen atmosphere is used. NICHIA recommends using a nitrogen reflow atmosphere.

5.Repairing should not be done after the LEDs have been soldered. It should be confirmed beforehand whether the characteristics of the LEDs will or will not be damaged by repairing.

6.The Die Heat Sink should be soldered to customer PCB. If it is difficult or impossible, use high heat-dissipating adhesive.

7.When soldering, do not apply stress to the LED while the LED is hot.

8.When using a pick and place machine, choose an appropriate nozzle for this product.

9.The soldering pad pattern above is a general recommendation for LEDs to be mounted without issues. If a high degree of precision is required for the chosen application (i.e. high-density mounting), ensure that the soldering pad pattern is optimized.

10.When flux is used, it should be a halogen free flux. Ensure that the manufacturing process is not designed in a manner where the flux will come in contact with the LEDs.

11.Ensure that there are no issues with the type and amount of solder that is being used.