Jet Type AP Plasma Processing System is long service life, low maintenance cost, easy to control customer cost, can be in-line installed in customer equipment production line, reduce customer input cost.

model no. :

FURY-APO-RP1020-D Plasma SystemBrand:

DSXUVport of dispatch :

SHENZHENPayment :

T/T 100% Before Shipmentoriginal region :

CHINA

Jet Type AP Plasma Processing System is long service life, low maintenance cost, easy to control customer cost, can be in-line installed in customer equipment production line, reduce customer input cost. The equipment is compact in size, convenient to carry and move, saving space for customers to use.

Parameters :

Name : Jet Type AP Plasma Processing System

Model : FURY-APO-RP1020-D Plasma System

Power supply : 220V/AC,50/60Hz

Power : 1000W/25KHz

Processing height : 5-15mm

Processing width : 20-80mm(Option)

Internal control mode : digital control

External control mode : RS485/RS232 digital communication port, analog control port

Gas : Compressed Air(0.4mpa)

Applications :

Various types of nozzles are available, which can be used in different occasions and meet different products and treatment environment.

RS 485 / 232 digital communication port and analog control port to meet the diversified needs of customers.

Small size, convenient to carry and move, saving customer space.

The In-Line type can be installed in the production line of customer equipment to reduce customer input cost.

Long service life, low maintenance cost, easy to control customer cost.

Mainly used in the electronic industry of mobile phone shell printing, coating, such as pretreatment, the surface treatment of mobile phone screen.

Surface cleaning for aerospace connector in national defense industry.

General industry screen printing, transfer press processing and so on.

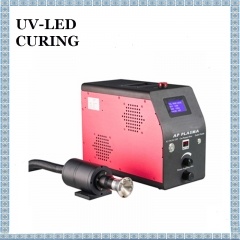

Rotary Round Sprinkle Head Jet Type AP Plasma Processing System

Rotary Round Sprinkle Head Jet Type AP Plasma Processing System

Jet Type AP Plasma Processing System FURY-APO-DP1020-A is mainly used in the electronic industry of mobile phone shell printing, coating, such as pretreatment, the surface treatment of mobile phone screen.

APO-RP1020D Plasma System Atmospheric Pressure Plasma Surface Treatment Machine

APO-RP1020D Plasma System Atmospheric Pressure Plasma Surface Treatment Machine

APO-RP1020D Plasma System Atmospheric Pressure Plasma Surface Treatment Machine is mainly used in the front processing of mobile phone case printing, coating and dispensing, as well as the surface treatment of mobile phone screen.

Mobile Phone Screen Cleaning Magnetic Levitation AP Plasma Processing System

Mobile Phone Screen Cleaning Magnetic Levitation AP Plasma Processing System

Magnetic Levitation AP Plasma Processing System Using magnetic power as power source, long service life and low loss. Long service life, low maintenance cost, easy to control customer cost.

Tip Nozzle Jet Type AP Plasma Processing System

Tip Nozzle Jet Type AP Plasma Processing System

Jet Type AP Plasma Processing System FURY-APO-DP1010-A is mainly used in the front processing of mobile phone case printing, coating and dispensing, as well as the surface treatment of mobile phone screen.

Atmospheric plasma surface treatment machine APO-RP1020D Plasma System atmospheric plasma low temperature jet cleaning equipment is a variety of nozzles are available for different occasions to meet different products and processing environments.

Customized Plasma Cleaner Atmospheric Plasma Low Temperature Jet Cleaning Equipment

Customized Plasma Cleaner Atmospheric Plasma Low Temperature Jet Cleaning Equipment

Atmospheric plasma surface treatment machine APO-RP1020D Plasma System Atmospheric plasma low temperature jet cleaning equipment , uses plasma cleaning, the cleaning efficiency can be greatly improved. The entire cleaning process can be completed in a few minutes, so it has a high yield;